Latest News

The first Paul McIntyre Award was also presented at the CED working day to Ulf Kivisäkk of Sandvik Materials Technology R & D, Sweden, by the ICorr President, Sarah Vasey. Paul’s son, Gerald and daughter, Anthea, were also in attendance and said some kind words about Paul. Ulf then gave a short talk summarising his contribution to the EU-funded programme on developing an ISO standard test method for assessing crevice corrosion of 316L stainless steel in marine environments (“CREVICORR”), and also his investigations into HISC of duplex stainless steels.

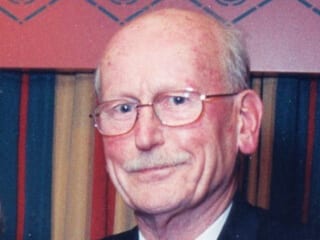

With Ulf Kivisäkk are Sarah Vasey, Nick Smart and Paul’s children, Gerald and Anthea.

Corrosion Engineering Division, Latest News

A CED Working day and Symposium on Corrosion Engineering and Concrete was held on Thursday, 27 April at IMechE Engineering Training Centre, Sheffield. The meeting was sponsored by the Institute of Concrete Technology. Some sixty delegates were welcomed by the Chair of CED, Nick Smart (Amec Foster Wheeler), who introduced the Division for the benefit of those who were not members and also outlined the programme for the day. This was followed by an ‘Introduction to the Institute of Concrete Technology’, given by the President, Raman Mangabhai.

Chris Atkins (Mott MacDonald) addressed, ‘The trouble with concrete’. He outlined the origin of the problems with concrete caused by shrinkage and the means of overcoming its poor compressive strength by inserting reinforcement. Settlement cracking was capable of giving rise to 2 mm wide cracks, which could penetrate right up to the rebar. Other aspects of steel corrosion in concrete were then discussed including the electrochemical mechanisms of corrosion, forms of chemical attack that can occur during use, repairing chloride-induced corrosion, cathodic protection, and decisions to repair (covered by BS EN 1504), with BS EN ISO 12696 providing further guidance on conformity.

Next, David Simmons (BAM Nuttall) outlined, ‘The use of coatings to manage corrosion in concrete’. “Getting it right first time” is a phrase that is often used in construction. This applies equally to reinforced concrete if it is to be durable and provide the service life as specified by the end-user. The problem with reinforced concrete is that while engineers fully appreciate the importance of including the reinforcing steel, not much consideration is given to the low-cost, easy-to-use, void filling material that surrounds it. In effect, the concrete cover should be regarded as a protective coating, and must be properly specified, batched and used, which can only be achieved by proper exchange of information between the designer, user, and producer of the concrete.

‘Impressed current cathodic prevention of steel in concrete’ was the subject of the lecture by Hugue Bois (SAPIEM SA, France). Theoretically, steel in concrete should not experience corrosion. The concrete pH is around 13 and this alkaline environment stabilises the iron oxide or hydroxide film, thereby passivating the embedded steel. The concrete layer also presents a low permeability barrier vs. external aggressive species, e.g. chloride ions or carbon dioxide. However, in some cases, ingress of these species reduces the pH to 8 or 9, thus impairing the passive film. Examples of field experience were given, including reinforced concrete steel piles, the use of Mn/MnO2 reference electrodes, and the importance of identifying the various at-risk zones, for example of a sea wall, viz. immersed wall, buried wall, atmospheric, splash and tidal zones.

The final presentation entitled, ‘Latest understanding of the corrosion of Magnox, aluminium and uranium metal wastes in cement’ was given by Hugh Godfrey (National Nuclear Laboratory). An overview of the work that has been carried out in the nuclear industry on the corrosion of Magnox (magnesium/aluminium alloy), uranium and aluminium wastes encapsulated in cements was presented under the following headings: the origin of the waste; how the waste is encapsulated in cement; how the corrosion rates were measured and a comparison of the corrosion behaviour of the three metals. Uranium has the simplest corrosion behaviour – an initial incubation period followed by continuous corrosion and a steady rate. Magnox behaviour is more complex, with the corrosion rate gradually decreasing to a fixed long-term rate. This contrasts with the corrosion rate for aluminium which continually decreases without appearing to reach a steady rate.

The technical talks from this meeting are available (in pdf form) on the members area of the ICorr website.

After the presentations, the delegates were afforded the opportunity of visiting the concrete and corrosion laboratories at Sheffield Hallam University, and to participate in CED Working Group Meetings. The concrete and CP, nuclear and coatings work groups all had successful sessions.

Latest News

Dr Charles James Louis Booker BSc, PhD (Lond), PhD (Cantab), FRSC, C.Chem, FICorrSt (Hon). 16 August 1930 – 1 March 2017

Charles J L Booker (always known by his work colleagues as Charlie) obtained an honours degree in Chemistry from Sir John Cass College and went on to achieve not one, but two PhDs! The first, in 1952 from University of London, was in Physical Chemistry, the second from Christ’s College Cambridge in 1962, was in Metallurgy. These established Charles as one of the brightest thinkers on the subject of corrosion. After his marriage in 1958 to Marylyn, he undertook a two year academic placement in Canada before returning to the UK to take up a post working under George Butler at the National Physical laboratory. Charles had a progressive view of education and strongly believed in the Polytechnic movement, and would encourage the new generation to consider higher education by giving talks at local schools. In 1965 he returned to City of London Polytechnic to become the Principal Lecturer and Course Director of the MSc in Corrosion Science and Engineering. It was whilst working there that Charles would leave his own great legacy. In 1928 and 1953 London had been struck by lethal flooding, resulting in the deaths of hundreds of people. In the 1970s a plan to create a strong flood defence barrier was born and Charles’ department was asked to lead a team of chemical engineers, tasked with ensuring the barrier’s longevity. With a group of committed colleagues he worked hard to ensure the barrier would elude corrosion in the generations to come (the Thames Water Barrier is not due to be de-commissioned until 2070, after close on century of quietly keeping watch over the city) After his retirement, Charles took a part-time voluntary Directorship at the Institute of Corrosion where he was Honorary Secretary for ten years (1992-2002), and at the conclusion of this period of service, a special award was instituted, (The Henry Cole award – a Poniard) for outstanding administrative service to the Institute, and Charles was the first recipient. He also served the European Federation of Corrosion as Honorary Treasurer in the years 2001-2004 where he worked closely with Paul McIntyre. Charles Booker was a man of distinction, whose loss will be keenly felt by his colleagues, friends and the three children and eight grandchildren that survive him.

Latest News

Supervisor Course

This new course is proving popular and has already been held three times in 2017. The course is available to any applicator who has two years’ experience following successfully completing the mandatory ICA ICATS module. Supervisors and Technical Managers who have more than two years’ experience in the industrial coating field will also be considered with supporting evidence from their employer, even if they have not completed the ICA course. Other candidates with at least five years’ verifiable experience in the coating industry will also be eligible.

For further details and course dates please visit our website www.icats-training.org and use the Supervisors Module tab, or call the Correx office on 01604 438222.

Company Trainer Course

We hold the Company Trainer Courses three or four times a year. Please contact the office for the date of the next course.

CSCS

As previously advised all new ICATS cards now incorporate the CSCS logo, confirming holders are suitably trained and qualified in Industrial Coating Application and they will not need another CSCS card to work on sites which require CSCS certification.

We are currently investigating converting to a SMART card system, so that the authenticity of the card and the holder’s details can be interrogated by Site Managers using a smartphone, tablet or PC allowing them to instantly record the cardholder’s information, and be secure in the knowledge that the cardholder is qualified for the job they do on site.

Further details of the CSCS Partner Scheme are available on the website under the CSCS Partner Scheme tab.

Keep up to date with ICATS using the website above or through the ICATS group on LinkedIn the business-oriented social networking service.

Fundamentals of Corrosion Course

This four day course (with an examination on day 5) has now been developed and is ready to be delivered. The first such course is scheduled for mid-September 2017. Dr Jane Lomas will be the presenter and it is likely that this first course will be held at IMechE

in Sheffield.

More details will be published in Corrosion Management when they are available.

Latest News

UK-based LUX Assure provides a revolutionary approach to the monitoring and management of production chemicals to both upstream and downstream oil & gas activities. Their pioneering technologies, inspired by their heritage as a life sciences research company, provide unique solutions for monitoring difficult to detect chemicals widely used across the oil & gas industry, and provide critical information to support key management decisions.

CoMic™ helps operators improve production efficiency by reducing surplus use of corrosion inhibitors, while still protecting asset integrity. It can also help to extend asset life, demonstrate best practice in corrosion management, and avoid the unwanted cost and separation difficulties that can arise from overdosing the pipeline, helping clients achieve optimal corrosion inhibitor concentration, every time.

OMMICA™ is an easy-to-use on-site testing kit that can rapidly determine MEG and methanol concentrations in produced oil, water and condensate.

An independent company, with global headquarters in Scotland and agents in the Americas, Middle East, Malaysia and Australia, LUX Assure serves customers worldwide. They are innovator in oil & gas intellectual property, and were ranked number 2 in the IP100 (2015), the UK’s Intellectual Property League.