Industry News, YEP

Can you present your research or a topic as an elevator pitch in just 3 minutes? Well, these Young ICorr members certainly can.

To celebrate Corrosion Awareness Day 2021, in collaboration with the European Federation of Corrosion and World Corrosion Organisation, four PhD students presented their research. The audience were treated to an informative presentation on hybrid FeCO3-poly(allylamine hydrochloride) deposition on carbon steel to improve corrosion resistance and characterising the associated mechanical properties and wettability by, Dlshad Shaikhah of Leeds University. Mohamed Alhebsi provided an in-depth analysis of pitting corrosion and SCC behaviour of CRAs in sweet and sour environments, to support industry applications. New techniques for understanding the erosion-corrosion phenomena revealing how time-dependent surface-hardening processes affect material loss rates during mechanical-electrochemical coupled corrosion, were presented by Aigerim Omirkhan from Imperial College.

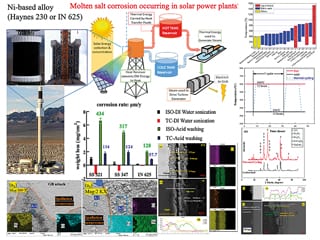

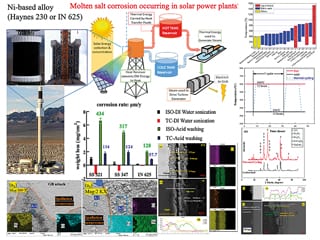

Competition was fierce and the standard of presentation was excellent. However, there had to be a winner, and Qingyan Liu from Leeds University’s whistle stop presentation on corrosion resistance of alloys to molten nitrate salt environments to support their use in solar power plants was the winner! Qingyan described how thermal cycling mitigates the corrosion rate and reduces the spallation behaviour of stainless steels compared with isothermal samples. Further analysis showed the multilayer corrosion products consisting of on the outside, sodium ferrite, and on the inside, iron chromium oxides. It was fantastic to find out about everyone’s research and the standard of presentation was very high. Many thanks to the judges, Bill Hedges, David Mobbs and Trevor Osborne.

Institute News

Bijan Kermani is the founder and Managing Director of KeyTech and a visiting professor at the University of Leeds. He has been involved in the field of corrosion for over forty years across the materials, metallurgy and corrosion disciplines within the oil and gas, geothermal, carbon capture and steel industries. He has a particular focus on materials optimisation, corrosion mitigation and integrity management. He has combined these activities with roles at various universities including Cranfield, Manchester and UCL.

Bijan is a leading authority on oilfield corrosion and materials and has more than sixty publications on his field of expertise related to environmental sensitive cracking, structural integrity and degradation, materials selection, steel development and corrosion control strategy. He has presented at numerous international conferences with many keynote lectures. He has edited two prominent publications on CO2 corrosion, and established a new methodology in material design for sour service duties which is now included in ISO15156. He has recently published “Corrosion and Materials in Hydrocarbon Production; A Compendium of Operational and Engineering Aspects” and also a “Recommended Practice on Pipeline Corrosion Management”. He has conducted many materials and corrosion control projects and training courses for leading oil companies, and has managed innovative projects for multinational companies globally.

Bijan is a Fellow of Institute of Corrosion and Fellow of Institute of Materials, a NACE Fellow, and the recipient of NACE 2007 Technical Achievement Award, a Chartered Engineer. and Instructor for various NACE International courses.

Institute News

CED Working Day, Wednesday 28 April 2021

This one-day meeting was the latest in a series of working days held by the Institute of Corrosion’s Corrosion Engineering Division (CED). This year’s meeting had the theme of ‘Managing Corrosion in Low-Carbon Energy Technologies’. As in 2020, it was originally planned that the meeting should be held at the National Railway Museum, York. However, due to the ongoing coronavirus restrictions, the meeting was again held on-line. Over a hundred people registered for the event, which was also an approved European Federation of Corrosion meeting. As we are all too aware, the topic of low carbon energy generation is an internationally important topic for the future of the planet and humanity, and which is rapidly gaining international importance. Managing corrosion in the evolving low carbon technologies is vital to the future success of such technologies. The symposium covered the management of corrosion in five different

low carbon energy technologies, namely hydrogen, wind, nuclear, biofuels, and carbon capture and storage.

Nick Smart (Jacobs) chaired the meeting, which followed the usual format and published agenda and timetable. Nick explained the operation of the CED, then thanked Ruth Bingham for her work as document editor in support of the CED, and welcomed Josh Zatland who has recently taken over the role. After the talks, the meeting divided into individual CED working groups, using the Zoom breakout room facility. At the end of the morning session, Bill Hedges, the Institute president, presented the 2021 Paul McIntyre Award to Bijan Kermani (see below), who gave an acceptance talk summarising some highlights of his distinguished career, after the main technical talks.

This article gives a brief summary of the talks enjoyed by the on-line audience, and presents some highlights from the working group meetings. The slides used by the presenters will be made available on the Institute’s website, together with recordings of the presentations. Minutes from some working group meetings will also be made

available in the members’ area.

The first talk on “Pipeline Materials in a Hydrogen Environment”, was given jointly by Nancy Thomson (SGN) and Julia Race (University of Strathclyde). SGN are responsible for the operation of many of the

local gas transport networks in the UK, which were originally

established in the 1960s to carry town gas (a mixture of methane, hydrogen, carbon monoxide and a range of other trace gases), but there is a plan to reuse the same transmission system for pure hydrogen in a future hydrogen economy. To achieve this it is necessary to demonstrate that the legacy materials used in the manufacture of the original pipelines will not be susceptible to hydrogen embrittlement, fatigue cracking or uncontrolled fracture. The metallurgy of the carbon steels used for the pipelines was reviewed, and the metallurgical characteristics that might increase susceptibility to cracking were discussed. The current supporting test programme underway at Strathclyde University and NPL was also outlined.

In the second talk, Birit Buhr Jensen (Ørsted) discussed “Cathodic Protection of Offshore Wind Power – Design using upcoming ISO 24656”. The presentation firstly covered an overview of the

remarkable expansion in the development of wind power in Denmark over the last 40 years, with a correspondingly large reduction in the cost of wind power facilities. Concrete gravity structures placed on the seabed are not normally considered to be in need of cathodic protection, however, protection may be needed in cases where premature deterioration has been observed, or if an unacceptable risk of corrosion exists in these offshore installations. Birit described the ongoing development of the ISO 24656 Standard to assist wind power operators to maintain these key assets for future generations, by taking account of critical environmental factors, such as seawater flow patterns and velocities, immersion levels and wave heights, in the design of the

CP system.

In the third talk Francois Ropital (IFP Energies Nouvelles) described corrosion challenges for reliable biorefineries. Biofuels have a key

role to play as part of the energy mix in the decarbonisation of future supplies during the next century. Francois described the background to some of the biofuels that are becoming available, such as ethanol and methyl esters derived from plant-based source materials (e.g. sugar beet and cane, oil from rape seed and sunflower seed), leading on to a discussion of the wide range of corrosion issues associated with the processing such materials. These include stress corrosion cracking (SCC) of carbon steel in ethanol production and alkaline processing media, uniform corrosion of carbon steel in acidic fluids at high temperature and pressure (related to total acid number, TAN, and sulphuric acid concentration), and corrosion in molten salts during gasification processes. The main conclusion was that each novel process for the refining of biomass needs to be considered individually, and that the development of suitable corrosion resistant materials is a significant challenge.

In the fourth talk of the morning, Stuart Medway, Jacobs, described a range of sophisticated advanced testing methods for testing the SCC and corrosion fatigue behaviour of structural materials for use in a pressurised water reactor environment, to support safety regulators in the nuclear industry. He emphasised that similar test methodologies could be applied to evaluating materials in other low carbon energy technologies, in aqueous, gaseous or molten salt-based environments, with strict control of the environmental chemistry required. He showed examples of techniques for testing multiple specimens in a single test, using DC potential drop technology to monitor crack growth, and the application of thermal cycling and thermal shock simulation. He also presented a recent novel development in which it is possible to

simulate multi-axial loading in a uniaxial test machine using

sophisticated specimen design techniques.

The final talk was given by Ivan Gutierrez (OGC Energy) on a methodology for corrosion and environmental assisted cracking risk assessment for industrial carbon capture, utilisation and storage (CCUS). The CCUS technology is important as a means of (i) controlling carbon emissions from energy-intensive industrial processes, where carbon release is unavoidable, (ii) extracting carbon from the atmosphere, and (iii) controlling carbon emissions during hydrogen manufacture. Ivan outlined the risk-based approach that is used to perform corrosion assessments of CCUS technology, by taking account of more than twenty possible corrosion mechanisms.

In the afternoon there was a set of parallel working group meetings

for all the CED working groups, namely nuclear, coatings, oil and gas, cathodic protection and corrosion in concrete, together with a general discussion group on the topic of corrosion in low carbon energy technologies. Highlights of the main working group discussions are summarised below.

At the end of the afternoon, Nick Smart thanked all the participants and contributors, and he looked forward to holding the next CED working day in person at the National Railway Museum next Spring!

Working group meetings (chairman):

Corrosion in Concrete (Chris Atkins): A summary of the current work by the structural concrete alliance was presented, plus an update of BS EN ISO 12696 (CP of reinforcement). Following this the floor was opened to discussion, with topics such as coating concrete and aggressive carbon dioxide attack discussed.

Coatings (Phillip Watkinson): The coatings group discussed the review and update of the nine coatings guidance documents that are currently on the Institute’s website in the member’s area. The chair will contact the original authors in the first instance, or seek alternatives if they are not available, to action the review and update. The group discussed possibilities and suggestions for the future direction of the group and reviewed recent news from the industry, such as the effect of Brexit on the activities of members. It aims to have an interim meeting before the next CED working day to progress the actions.

Oil and Gas (Alistair Seton): The status of the working documents was reviewed and the future direction of the group was discussed. It was decided to change the title of the working group from ‘Oil and Gas’ to the ‘All Energy’ Working Group, to encompass the current status of renewable energy and the alternative energy strategy. There was a brief discussion on the status of API 510 and API 570 in the UK. Steve Paterson agreed to take over chairmanship of the newly named working group, as Alistair Seton was stepping down as chairman after four years in the position. Stephen Tate, the Institute’s vice president, expressed the Institute’s gratitude to Alistair for his contributions to the group since joining as chair.

Cathodic Protection (Bryan Wyatt)

Brian Wyatt chaired the meeting on an interim basis, as Pablo Merino had stood down as chair at short notice. It was noted that there are many other forums for discussions about CP and the main discussion was around the future role of the CED CP working group. The consensus was that there may be a role to interface between the younger Institute members with some interest in CP and more experienced practitioners. There was a proposal for a small number of half-day seminars to be run by the Institute every year, comprised of a CP Design Tutorial and an ‘Ask the Experts’ session. The arrangements for such events are under discussion. There was also some technical discussion regarding the morning presentation on the new EN ISO 24656 Offshore Wind CP Standard.

General discussion group (Steve Paterson)

Following the presentations on the day, a discussion forum was held in the afternoon to review key points arising from the morning presentations, and to gauge interest in forming a working group to cover this emerging theme. The discussion covered reusing existing pipelines for hydrogen transport, cathodic protection for offshore wind turbines, issues with production of biofuels, and corrosion concerns with carbon capture and storage. The discussion was supplemented with information about other ongoing initiatives in this field including: (i) a new EFC task force set up to promote information exchange around corrosion in green and low carbon energy technologies, (ii) a workshop on this topic at the virtual Eurocorr 2021 conference, and (iii) a guidance document being developed by the World Corrosion Organisation. It was also agreed during the discussion forum that the theme of corrosion in low-carbon energy technologies should be developed further as a specific focus area within the CED Oil & Gas Working Group because of the many synergies and current industry trends relating to low carbon energies (see above).

Institute News

I would like to thank our clients for their continuing support during a very difficult period for us all.

While we have been unable to carry out face to face training, online training has worked very well and continues to do so. It remains our intention to continue with ICATS online and to develop that concept going forward through 2021, whilst also to begin face to face training at Corrosion House later this year, providing restrictions continue to be lifted, and additional safety procedures can be put in place at Corrosion House. Once a decision is made dates will be added to the ICATS website.

Trainer training has been very popular during Covid 19, with companies using ‘down time’ to update and increase qualifications, and increase the numbers of their ICATS trained operatives. The ICATS ‘managers course’ has also been very popular with multiple managers, engineers, specifiers, taking the one-day course and increasing their knowledge as to what is actually done on site.

I often get asked about CSCS cards and how they work. Upon successful completion of the ICATS, ICA, Industrial Coating Applicator course, a person then gets awarded their ICATS card with the CSCS logo embossed onto the card for identification on site. This is the approved method of CSCS recognition for them as painters on site. The cards are considered a “T Level” card, of which our category is ‘building services’. Cards can be checked on the ICATS website by using our card checker for validation using

smart technology’.

At some point in the first quarter of 2022, smart cards may be introduced, so that they can be read at multiple locations, for easier identification purposes.

We are due to have trainer seminars in accordance with the ICATS Requirements, however even with current restrictions gradually being lifted, it would not be appropriate to hold seminars at this time. Therefore, I will be considering an online portal containing new and pertinent information that can be accessed by trainers, supervisors, managers etc, that will be available later this year.

Kevin Harold, CORREX Managing Director

Institute News

Hello everyone, it’s been another busy and productive two months for our ICorr members so I’ll start with a quick review of that. In April the annual Corrosion Engineering Division (CED) working day was held virtually with over 60 participants for the full day. I sat in for the whole meeting which was very successful and provided a good balance of excellent presentations and break-out discussions. Many thanks to Nick Smart, our CED chair, for pulling together another great networking event.

A few days later Caroline Allanach, our Young ICorr chair organised a “Thesis in 3 minutes” on-line event where several young engineers gave enthusiastic talks based on their current work. As you might expect it was a fast-paced event and I was impressed by how all the participants presented so much information, very clearly in such a short time. They all did well and congratulations go to Qingyan Liu from The University of Leeds who won the competition for his talk on the corrosion resistance of alloys in molten nitrate salt environments, to support their use in solar power plants.

In early May, Stephen Tate, VP, and myself, had our regular catch-ups with the leadership of AMPP (the new name for the merged NACE & SSPC societies). Whilst we all recognise and respect that we compete in the area of providing training there are so many areas where we have mutual interest and goals. As an example, we held a joint meeting on Additive Manufacturing recently which was very successful and there are several areas where we are looking to cooperate further.

On the 10th May I was delighted to attend the opening of our new CP training facility at Corrosion Control Services Ltd. (CCSL) offices in Telford, UK – my first official presidential visit since the Covid restrictions. You can read more about this in this issue.

On the subject of training there is a lot happening and one highlight I’d like to mention is that we have agreed to be a founding member of the European Federation of Corrosion’s (EFC) new training course approval scheme. We will be submitting several of our training courses this year which, once approved, will allow us to use the new EFC approval logo when advertising them. Our expectation is that this will allow us to reach a wider audience with our training offer. Many thanks to Trevor Osborne and Brian Wyatt who represented ICorr on the EFC project team and ensured our views formed part of the programme.

One of the many benefits of ICorr membership is that we offer the highest level of professional accreditation with both Chartered Scientist (CSci) from the Science council and Chartered Engineer (CEng) from the Engineering Council. These are prestigious attributes and, as you might expect, there is a high level of quality control and audit that we must adhere to for retaining our license to issue them. In May we had our license review with the Science Council which went very well and the auditor’s recommendation was that we retain our license to issue CSci. This is a great result, and I would like to thank Brenda Peters, Paul Lambert and Douglas Mills for their hard work to ensure all of our procedures and documentation is up to date. On the same day as our review, I was delighted to hear that Brenda has been approved as a Board Member of the Registration Authority of the Science Council – Brenda many congratulations.

In my last column I mentioned that several of you had contacted me with suggestions to update our website and members database. As a result, Stephen Tate (VP), Denise Aldous (ICorr office manager) and Jonathan Phillips (Square One – our website managers) are now working on a proposal to do this which will be presented to the ICorr Council at the next meeting. It will likely be broken into phases spread over several years to ensure that we prioritise the most important things and get them completed in a timely manner. If you have any suggestions for improvements that should be made to our website, please don’t hesitate to contact me at the email below.

Finally, I’d like to mention the great work that Kevin Harold and the board of Correx are doing to improve and deliver the Industrial Coatings Applicator Training Scheme (ICATS). For those of you who may not be familiar with Correx it is an independent company that is owned 100% by ICorr. Despite the difficulties as a result of Covid, Correx has continued to perform well and is working on several exciting opportunities to provide our training overseas.

I do hope all of you are keeping well.

Until next time,

Bill Hedges, Institute of Corrosion President

Email: president@icorr.org