Institute News

The branch has arranged a technical talk in December, to be held in the IMME offices in Newcastle, from Ing. Britt Gevaert, Acotec, Belgium, on their Humidur® brand of Passive Fire Protection coatings.

The branch is also organising a two day “Sustainability Conference “in 2023, in collaboration with IMME.

Continuing with the introduction of the committee members of the newly reformed branch announced in the last issue.

Treasurer: Josie Terri Watson, is a Project engineer at Metec Cathodic Protection. She works in the technical department generating engineering documents such as manufacturing drawings and inspection test plans. She will be a great asset to the Committee and demonstrates the wide span in experience to the branch. Josie hopes to raise awareness with the youth and female members, and she will be the Young ICorr.

Events: Matt Fletcher is currently Global Linings Product Manager at International Paint. In addition to his masters degree in Mechanical Engineering from Newcastle University he is Diplom-Ingenieur (FH), SSPC Concrete Coatings Inspector Level 2, and has a Professional Diploma from the Chartered Institute of Marketing.

Patrick Johnson is currently Technical Marketing Manager with Carboline Europe and has extensive experience in the coatings industry R&D, business development, sales management and marketing.

Secretary: Chris Langley has been working in the Coatings industry for 35 Years, and most of his career has been in the energy sector and chemical industry, focussed on corrosion inspection, and project managing fabric maintenance projects. He is currently a Field Consultant with the Safinah-Group, working in the energy and offshore sectors.

Barry Turner has also joined the committee. He is a very experience technical, sales and marketing professional with almost 40 years experience in industrial coatings. He is a recognised expert in pipe coatings and sits as a representative of the UK on ISO standards development groups for pipe line coatings, and is now working as an independent consultant.

Institute News

The branch committee has been strengthened by some younger ICorr members, and the new committee met over the summer to discuss how best they can meet the needs of members, and developed the following mission statement.

The Branch’s mission is to promote the understanding of corrosion, its impact, and how to mitigate it, in the various industries, through community knowledge sharing and transfer. The Branch also aims to meet the needs, and provide networking opportunities, for local ICorr members and the greater engineering community in London and beyond.

Following on from this, a questionnaire was sent out to the branch members asking for their views on how we can fulfil this statement, and these are being analysed. The branch is also looking for new committee members, so if you are interested, please get in touch.

The first meeting of the 2022/2023 season will be on 13th October at the usual venue, The Lancaster Hall Hotel, Bayswater, when Anthony Setiadi, Wood Thilsted Partners, will present “Corrosion protection considerations for offshore wind foundations”. This presentation will primarily focus on monopile foundations, and the design considerations that would need to be taken onboard.

Details of future branch technical meeting can be found on the diary page of the magazine.

Institute News, Uncategorized

The May meeting of the branch was a hybrid presentation from the Palm Court Hotel by Martin Worth, Director, Plant Integrity Management (PIM), entitled: SECEs: It’s time for a rethink!

The recent anniversary of the Piper Alpha disaster reminds us all of the need for effective safety controls. Our UK Oil and Gas industry was shaken to its core on 6th July 1988, when 167 people perished in the fire and explosions, and many others were traumatised and injured.

The subsequent Cullen inquiry, which took 2 years to complete, led to the Safety Case Regulations* being established, and the Offshore Industry thereafter moved to a goal setting safety regime, characterised by the introduction of PFEER (Prevention of Fire and Explosion, and emergency Response on Offshore Installations), and DCR (Design and Construction Regulations) – put in place to ensure that duty holders of offshore installations dealt appropriately with the requirements to provide measures to prevent, mitigate and respond to major accidents. * See, HSE website:

The Offshore Installations (Safety Case) Regulations 2005 – SPC/ENF/158 (hse.gov.uk)

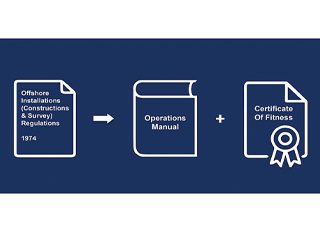

Prior to the Safety Case Regulations there was the 1974 Offshore Installations Regulations, which required that there was an Operations Manual and a Certificate of Fitness. These were prescriptive regulations, and were all about certification. These documents were essentially ‘How to build and operate an offshore platform’ and specified six organisations that you needed to use to certify your platform operation.

Piper Alpha Incident 6 July 1988

Lord Cullen Enquiry Report.

However, during the Cullen enquiry there was the immediate introduction of the “Forthwith Studies”, in advance of, and in preparation for, the Safety Case requirement for each asset by UK Operators. These identified areas requiring priority attention:

• Emergency Systems Review (ESR)

• Smoke and Gas Ingress (SGI)

• Fire Risk Analysis (FRA)

• Evacuation, Escape & Rescue (EER)

This was put together by large teams within the industry, but was second guessing what might be required when the Safety Case regulations came out.

These new Safety Case Regulations involved a formal Safety Assessment process, based on goal setting.

1. Identify Major Accident Hazards (MAH)

2. Identify all Mitigation Measures and Barriers

3. Specify Measures (SECEs and Performance Standard Criteria)

4. Apply the Performance Standards Process (Maintain/Assure/Verify)

Performance standards based around Functionality, Availability, Reliability and Survivability became the norm. Today, these are referred to as the “Safety and Environmental Critical Elements (SECE)”, and according to the regulations, can be either hardware or software based, including management systems.

Setting performance standards for certain types of hardware can be very challenging. For example, a performance standard for a pipe or vessel may state that it shouldn’t leak, but in practice we shouldn’t be waiting for items to leak before we consider them to have failed as SECEs.

Martin debated that any hardware-based system shouldn’t be the principal SECE, and that while many operators today claimed to be carrying out assurance, in practice some were doing little more than performing inspections, incorrectly leaving the assurance elements of the process to the verifier.

Following on from this, Martin suggested that changing the emphasis of SECEs to focus on Management Systems and Integrity Management Systems (IMS) would deliver increased efficiency and reduced costs. As, if it can be demonstrated that the IMS is well formulated and correctly implemented, this will automatically confirm that the elements it covers are inspected, their functionality confirmed, anomalies managed, repairs carried out, backlogs controlled, planning addressed, and their condition endorsed. Thus, removing the need for the specific assurance of individual items.

Martin’s presentation was very thought provoking and again featured significant international attendance with a comprehensive Q&A following the event.

The Presenter

Martin graduated from the University of Liverpool in 1988 with a First-Class Honours degree in Physics, and has had over 30 years of experience within the field of safety management in the oil and gas industry, and was one of PIM’s founding Directors. As an established figure within the oil and gas industry, his breadth and depth of experience has been gained through a variety of technical safety roles within both operator and consultancy environments, specialising in safety management but having particular interests in the linked fields of: risk management, process safety and risk-based decision making.

Upcoming Events

The branch is now looking forward to its AGM planned for September 2022, ahead of the start of the new technical sessions at which a new committee will be elected.

The next event of the 2022-2023 calendar after the Annual

Corrosion Forum in August, will be a joint one with TWI. This will be given by Neil Gallon, Principal Engineer of Rosen, with a talk on “Re-purposing of Pipelines for Energy transition” – Thursday 22nd September 2022 at 6pm. Abstracts of potential papers for its Technical Programme are always welcome, and anyone wishing to join committee should correspond with: Hooman Takhtechian, htakhtechian@oceaneering.com

Process Pre-Safety Case Regulations.

Process Post-Safety Case Regulations.

Institute News

The European Federation of Corrosion has made an Honorary Fellow Award to Dr Douglas Mills, well known to members of ICorr (he was Technical Secretary 1999-2017).

The EFC jury recognised his outstanding accomplishment in the field of interpretation of electrochemical response of coatings on metals using techniques such as Electrochemical Impedance Spectroscopy (EIS) and particularly Electrochemical Noise (EN). He has also had a positive and long-term devotion to the EFC, with active involvement in a wide range of EFC Working Parties, in particular WP 14 (Coatings), but also WP 8 (Physico-chemical Methods of Corrosion Testing), WP 21 (Corrosion of Archaeological and Historical Artefacts), WP 1 (Corrosion & Scale Inhibition) and WP 11 (Corrosion of Steel in Concrete). He has submitted papers to all of these working party sessions at EUROCORR at various times. He has also attended and presented papers at most of AETOC (Advances in electrochemical techniques for organic Coatings) workshops /conferences that arose from the EFC coatings working party. He has supported EFC activities by being Editor of the EFC Newsletter from 2016 to 2022, and by providing regular scientific EUROCORR reports in the Corrosion Engineering Science and Technology journal.

This award is a nice recognition of Douglas Mills’s contribution, not only to the EFC, but more generally to corrosion science and technology. He will receive it in person at the opening ceremony of EUROCORR 2022 which will be held in Berlin on August 29th.

Institute News

The most recent ICorr, ICATS apprentices have been deeply affected by Covid over the last 18 months. With college staff being unwell leading to eventual loss of staff and students unable to attend college and other factors, the final End Point Assessment was carried out on the 20th July with one student only.

That student, Rory Voulgar, was a credit to himself and the Jack Tighe organisation for seeing it through to completion.

The day started with the professional discussion between myself, John Moody, BINDT, and ICATS senior trainer Robert Hurley and of course Rory.

Rory’s answers were clear and concise, and he remained so for the hour duration discussion.

This was followed by the practical session to test Rory’s preparation and application skills. Once more he was able to demonstrate all the skills necessary to become a fully trained ICATS apprentice.

After completion of the EPA, we were very proud to announce to Rory he had achieved the grade of ‘distinction’.

Other news

With all Covid restrictions removed our work at the larger asset owners and projects has resumed once more, and this is particularly true of the nuclear facility Sellafield in Cumbria. I recently visited Sellafield to see Eddie Blackmore, Jacobs Coatings Manager, who will be teaching all of the ICATS courses from the Jacobs main office at Sellafield. This is an amazing development for ICATS and we look forward to working with Eddie on his quest to progress all things paint and quality.

I have started travelling once more to visit our clients and further develop ICATS. I am also being helped in this by David Mobbs and senior ICATS trainer Robert Hurley.

KevinHarold,

CORREX Managing Director