Institute News

On Tuesday 26th September 2023, the Aberdeen Branch meeting welcomed Alyshia Keogh from the University of Manchester with a talk entitled Effect of Microstructure on the Localised Corrosion and Atmospheric Stress Corrosion Cracking of 15-5PH Stainless Steel. Alyshia completed undergraduate studies in Materials Science and Engineering at the University of Sheffield and, after spending some time working in the heat treatment and manufacturing industries, she is now in her final year of her Ph.D. at the University of Manchester.

The primary goal of the Ph.D. is to study the effect of heat treatment condition of a 15-5PH Stainless Steel. on its susceptibility to pitting and atmospheric induced stress corrosion cracking (AISCC) with the aim of aiding design of future alloys. The underlying microstructure of the heat-treated material was studied as a function of ageing treatment and linked to the materials susceptibility to corrosion through a series of specific tests. To this end, samples of 15-5PH stainless steel, in the solution heat treated condition, were aged for 4 hours at 3 different ageing temperatures of 450 °C, 540 °C and 650 °C to give ‘underaged’, ‘peak aged’ and ‘overaged’ conditions, respectively.

Solution treatment of the material at a temperature of 1038 °C for 1 hr obtains fully martensitic microstructure with small amounts of retained austenite. Subsequent ageing at a lower temperature forms fine Cu rich strengthening intermetallic precipitates through the matrix while also causing austenite reversion and some possible carbide formation, which can be detrimental to the performance of the material.

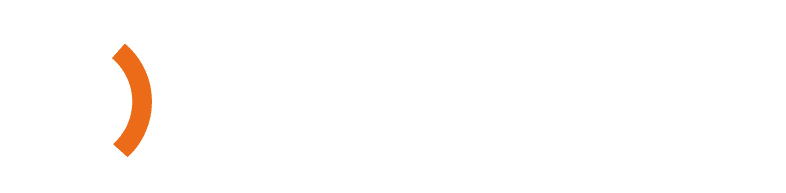

Microstructural evolution was characterised using mechanical testing (Tensile and Hardness) Increase in ageing temperature resulted in a rise in hardness and strength to peak aged, with ductility increasing and strength falling towards the over aged (650 °C) condition. XRD was used for austenitic phase fraction (w.r.t temperature) measurement and Scanning and Transmission Electron Microscopy (SEM and TEM) with EDX analysis was used for microstructure and phase analysis. Austenite fraction increased from 2.4 to 2.7 and up to 24 % with ageing Austenite nucleates along with boundaries and PAGBs with Austenite reversion far greatest with the 650 °C ageing treatment. The austenite content is known to have a direct impact on the mechanical and corrosion properties of the material. Element mapping using XRD showed the distribution of elements in the microstructure and reveals Cr and C concentrations at particles and grain boundaries; these were only present in the peak and overaged samples. Cr depletion areas are suspected to be initiation sites for localised pitting corrosion, particularly in the over aged condition. A line scan across the carbide particles shows the enrichment at the particle and depletion at the boundaries.

To study Corrosion properties, a number of techniques were employed including Potentiodynamic Polarisation which was used to study Pitting susceptibility using an Avesta Cell. However, while the 650 °C condition had the lowest E pit potential, the scatter in results was found to be too great to be statistically significant.

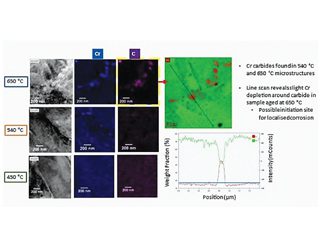

Differences in pitting behaviours were also assessed using Double Loop electrochemical reactivation (DL-EPR) This assesses the passive film layer integrity and detects the loss of passive film on grain boundaries where Cr depletion has led to sensitisation. The test uses an electrolyte of sulphuric acid and potassium thiocyanate and sweeps the surface with a potential which, upon return sweep gives a current difference identifying the activation peak. This technique showed there was a linear trend in degree of sensitisation with ageing temperature which correlated with the increase in the presence of Cr carbides.

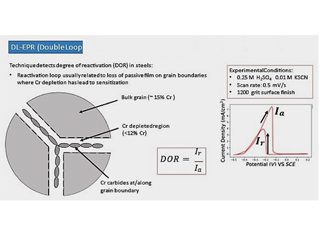

Another technique was used to study pitting susceptibility using electrochemical noise, which is measured by galvanically coupling dissimilar microstructures in an electrolyte. The results suggest that the higher temperature ageing treatment, which produced the most metastable pitting events, may have a higher probability of transitioning to stable pitting.

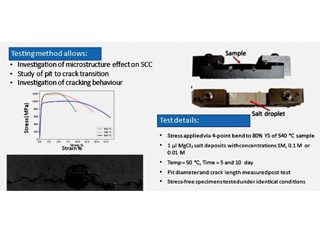

Four-point bend specimens with Cl- salt deposits exposed to controlled temperature and humidity were used to study the link between pitting behaviour and cracking. The test details are shown in the enclosed slide whereby stress is applied to a test sample with salt droplets on for different times and humidities. The samples are studied under an SEM and the microstructure, extent of corrosion and crack development can be imaged in detail.

The results of this study revealed that higher ageing temperatures (650°C) were more resistant to cracking. In addition, the mode of cracking changed from an intergranular pathway in 450 °C specimens to mixed-intergranular and trans-granular in 540 °C while no cracks were observed in samples aged at 650 °C.

In summary, the 650 °C microstructure was shown to be the most susceptible to pit initiation in the electrochemical tests through the greater frequency of detected metastable events. This is likely to be related to the Cr depleted zones associated with the carbide formation or the lower Cr content in reverted austenite. However, the 650 °C material seems to be the most resistant to environmental cracking in the environmental stress tests.

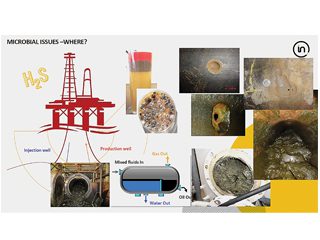

On Tuesday 31st October 2023, the Aberdeen Branch meeting welcomed Heike Hoffmann Consultant Microbiologist, Intertek, Aberdeen with a talk entitled Monitoring to combat Microbiological Issues in Oilfield Process Systems – Understand the Option for Better Visibility. Dr. Heike Hoffmann joined Intertek (formerly Commercial Microbiology) in 2006. After setting up the molecular laboratory and establishing the services within the company she is working as a Consultant Microbiologist supporting Intertek’s Oil and Gas clients with all aspects of controlling and managing microbiological growth within their ‘on- and offshore’ installation, ranging from Microbiological Influenced Corrosion (MIC), Biocide Optimisation, and Reservoir Souring as well as leading on bespoke, issue-based projects. Heike Hoffmann has a Diploma in Biogeochemistry from the University of Hamburg and in 2004 she gained her PhD entitled “Investigation of the effect of biocides on soil bacteria by microbiological and molecular-biological methods” from the University of Hamburg.Her talk was entitled – Monitoring to combat microbiological issues in oilfield process systems and understanding the options for better visibility. Even after over 35 years of practical field experience and routine monitoring in the endeavour to effectively manage microbiological proliferation and control MIC, failures still lead to unplanned shutdowns, repair and replacement costs. Over the last decades, a suite of microbiological and molecular methods has become available to the oil and gas industry to gauge the adverse effect of microbes in oil and gas installations. Extensive effort has been made to understand and act accordingly on the output of these different techniques and interpret results gained from these analyses to best effect.

The presence of microbes within the production side of oil and gas production is essentially due to the injection of seawater into the well to facilitate the extraction of the oil from the reservoir. Seawater filtration pumps attempt to filter out marine life, solids, plankton and algae thus restricting the presence of organisms and minimising impurities and organic matter that are injected into the wells. Oxygen is stripped out of the system using Paul rings and scavengers. Once the purified seawater is within the system there will be suitable conditions for any remaining microorganisms to thrive

The organisms can essentially deposit and grow on internal sides of the production piping and processing vessels, and multiply to form corrosive films which can consume metal on the inside of the pipes leading to wall thickness, loss of integrity and even failure of pipework systems. The biofouling causes lack of flow assurance and unwanted reservoir plugging, reservoir souring occurs, and we get oil separation issues in flotation and hydrocyclone vessels.

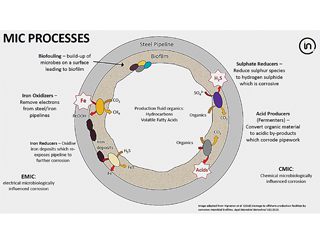

The principal mechanisms of MIC in Oil and Gas industry are:

• Sulphate reducing bacteria (SRB)

• General Heterotrophic Bacteria (GHB)

• Acid Producing Bacteria (APB)

More recently molecular method reveals the involvement of other organisms such as Sulphate reducing Archaea (SRA), Methanogens, Iron reducing bacteria and minor other types.

MIC is corrosion due to the presence and activity of microorganisms and studies show that it may account for up to 20% of the $20 trillion global cost of corrosion. The greatest threat is from SRB which are a diverse group of anaerobes utilising sulphites (SO2) the produce sulphide (S2). Several mechanisms have been proposed which include, amongst many, cathodic or anodic depolarisation, enzyme dehydrogenase and the generation of iron sulphides.

Sampling and monitoring are conducted to generate appropriate data in order to predict areas of risk and identify the source of microbiological contamination. It also helps to setup mitigation strategies and monitor the effectiveness of these strategies.

Molecular methods are used in the oilfield to improve sensitivities and reduce analysis time. These are ‘None PCR’ (Polmerase Chain Reaction) based methods, such as Flourescence in-situ Hybridization (FISH) and PCR based methods of Quantitative Polymerase Chain Reaction (qPCR) and Next Generation Sequencing (NGS). So the types and scope of analyses used in testing samples range as follows:

Range of testing samples

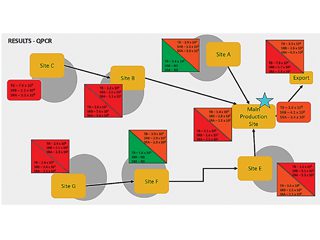

A case study was presented in which the aim was to determine the source of contamination which was causing the build-up of ‘biofilm’ at the main contamination site. The site contained 100 gas fields and > 55 oil fields currently in production on an onshore site. There were: 500+ producing gas fields and more than 200 producing oil wells. These were all feeding into a production site through kilometres of pipeline and flowlines via ~ 10 major satellite facilities. Water for the production was from bores and reverse osmosis treatment plant.

The qPCR tests on various sites revealed the sites and process lines which had the greatest amounts of contamination and helped identify areas for more detailed study using NGS techniques to identify the lines from site C and site B where the main source of contamination at the main production site and major contributor to contamination in the export product. The operators were able to then take action in specific sites where the microorganisms were multiplying and reduce the contamination within the exported product.

All methods have limitations when utilising the techniques to trace contamination, but the use of a combination of techniques can identify the strains of microorganisms and help eradicate the process problems. Molecular analysis, especially NGS, will give good indication of what is there, and MPN analysis gives indications as to what can grow in the system. qPCR (DNA based) gives indication of what is in the system and can grow if conditions are favourable. Monitoring for microbial contamination gives the indication of potential risk, and this is why regular testing is key, along with collecting meta data and trending the data.

Abstracts of potential papers for the Aberdeen Technical Programme are always welcome, and anyone wishing to present should correspond with the 2024/2025 Technical Programme Co-ordinator: mei ling cheah meilingcheah@gmail.com.

Further Information about the Aberdeen Branch, and past presentations, may be found on their website page: Aberdeen Branch – Institute of Corrosion (icorr.org) and to join the Aberdeen Branch mailing list, please contact: icorrabz@gmail.com.

Please also note that the Institute is now offering three levels of MIC training.

• MIC Awareness

• MIC Technologist

• MIC Certified Technologist

Refer to: ICorr Microbiologically Influenced Corrosion Courses – Institute of Corrosion for further information.

CAPTIONS:

Alyshia Keogh, a Ph.D. Student at the University of Manchester.

Chromium carbide precipitation as a function of ageing temperature.

Effect of ageing temperature on passive layer integrity using DL-EPR (double loop electrochemical potentiokinetic reactivation).

Comparison of pitting susceptibility via electrochemical noise.

Susceptibility to environmentally assisted cracking.

Dr. Heike Hoffmann PhD, Intertek Consultant Microbiologist.

Multiple locations of MIC issues.

An overview of MIC processes.

Results of QPCR analysis.

Institute News

Welcome to the November/December issue of the magazine. As 2023 comes to an end, I would like to express my gratitude to Stephen, Brian, the Square One team, the ICorr team, and all the authors who have contributed to the Corrosion Management Magazine. The success of Corrosion Management Magazine is ensured by our joint, committed efforts. I wish a happy and festive Christmas to every reader.

This issue is dedicated to the theme “Sustainable Energy”. The first technical article “How do you take sustainability into account during design?” is written by Birit Buhr. She has proposed that environmental impact be considered during the design process by including life cycle analysis (LCA) to minimise environmental impact over the lifetime of a structure. Dr Patricia Conder has authored the second technical article titled “Non-Destructive Challenges in the Net Zero World”. Five facets of inspection- degradation, physics of inspection, Inspection deployment, planning and data analytics are described to tackle key Net Zero NDT challenges by Dr. Conder. The third technical article, entitled “An Examination of Localised Internal Corrosion Failure Mechanisms for a Nutshell Filter Vessel,” is written by Riky Bernardo. Dr. Douglas Mills has also contributed an article for the Fellow’s Corner titled “Archaeological Corrosion and Conservation,” which is primarily historical and based on previously published work.

To help you learn more about the columnist, we have included a “Meet the Author” section with every article.

We welcome industry news, technical articles, and articles for fellow’s corner from you in whichever part of the world you are based. Your suggestions and feedback are very important for ensuring that we deliver magazine content that will engage our valued members. Please send all your content for consideration.

editor@icorr.org

Dr Shagufta Khan, FICorr

Consulting Editor