Institute News

On November 28, 2023, the Aberdeen Branch meeting welcomed Dr. Douglas Mills and Tianyang Lan with an online talk entitled ‘Assessment of anti-corrosive organic coatings and green corrosion inhibitors by electrochemical techniques, particularly electrochemical noise measurement (ENM).

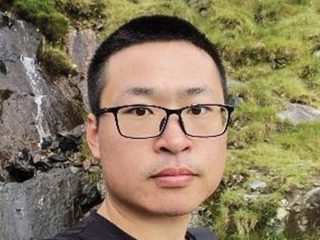

Douglas Mills gained a PhD in anti-corrosive coatings from Cambridge University, and after spells at the BNF Metals Technology Centre and the Nuclear Power Company, he has worked in academia and has continued to conduct and supervise research in the field of electrochemical methods for application to coatings, studying and advancing the electrochemical noise method. He was for fifteen years the Technical Secretary of the Institute of Corrosion and is also involved in standards development.

Recent Developments in Electrochemical Noise Measurement (ENM) Techniques

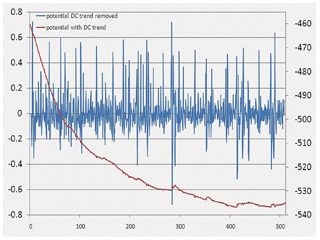

ENM is a series of techniques that can be used to assess the corrosion protection effectiveness of organic coatings. The advantages of the techniques are that they are non-intrusive and both ‘quick and easy’ to operate. The interpretation of the gathered

data is not complicated. The main purpose of ENM is to obtain a single parameter, the Noise Resistance (Rn) which relates to protective ability.

This is the standard deviation of the potential series / standard deviation of the current series.

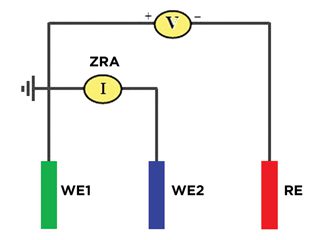

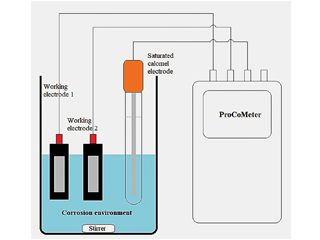

To obtain an R value, three electrodes are required: two nominally identical working electrodes (WE1 and WE2) and one reference (Re). The natural fluctuations of voltage (potential noise) are measured between WE and RE. At the same time, the natural fluctuations of current (current noise) are measured between the two WE electrodes.

The EMN data is typically gathered over about 4 minutes at 0.5-second intervals (512 data points). Repeat runs are made.

The criteria developed in 1948 by Bacon, Smith and Rugg defined the following:

• less than 106 Ωcm2 – poor corrosion protection,

• between 106 Ωcm2 and 108 Ωcm2 – intermediate level of corrosion protection,

• more than 108 Ωcm2 – good corrosion protection.

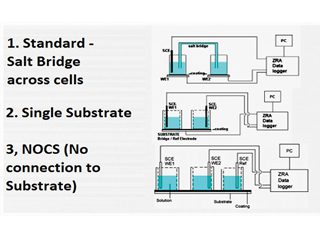

There are a number of different configurations of Electrochemical Noise Measurement techniques as shown in the schematic the Standard Bridge method, the single substrate, and the NOCS termed ‘No Connection to Substrate’.

The experimental work had the following aims:

1. Examination of different arrangements of ENM on a range of coated samples and comparison between them.

2. Checking the reproducibility of results and considering the more practical application of this technique in the field.

3. Investigation of NOCS arrangement of ENM.

Mild steel Q-panels were coated with an appropriate coating in the laboratory by a spreader bar.

The types of coating used in the experiments were mainly polyurethane with some Alkyd and others such as Waterborne Epoxy. To get exposure of the coated plates to the corrosive solution, plastic tubes were attached to the samples and sealed with silicon before filling with 3% Na Cl solution- the area of exposure was ~ 4 cm2. Saturated Calomel electrodes were used to measure the Electrochemical noise. An electrometer (Keithley 610) was used to make DC (Direct Current) measurements to compare Rn values with DC resistance values.

Reproducibility experiments were conducted over a period of 5 days, and they demonstrated that the technique gave stable results after multiple set-ups of the experimental apparatus.

A study was conducted to establish if one area of higher or lower resistance could be detected using the apparatus, i.e., if the Rn value of one area was different than for the other two, are we able to detect the odd one? If so, could we measure its value? A design experiment was set up using all permutations to compare high and low combinations of the coated plate resistances.

Designation of Cell DC Resistance Value (Ω)

A 6,40E+09

B 6,35E+09

C 6,40E+09

Designation of Cell DC Resistance Value (Ω)

X 5,50E+07

Y 1,05E+07

Z 1,30E+07

Six areas were used, three with high resistances A, B, C and 3 with lower resistances X, Y, Z, six combinations altogether.

In conclusion for this work, one single NOCS measurement, made with ACM equipment, when one cell was different from the other two, the research team could, by making multiple measurements, obtain the different value of Rn in the combination when the odd one was connected to WE1.

Using ECN for Green Inhibitor Testing

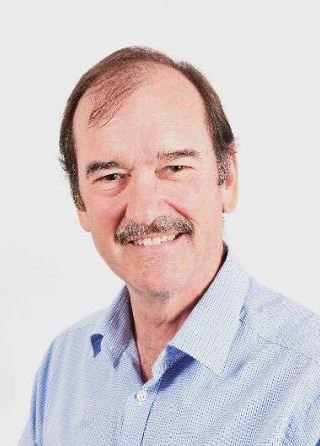

Tianyang Lan of DC Voltage Gradient Technology and Supply Ltd (DCVG).

Tianyang Lan has obtained both a BSc and MSc in General Engineering at the University of Northampton. During his studies, he conducted some Electrochemical Noise research projects under the supervision of Dr. Mills. He has worked as a researcher at the University of Nottingham, Department of Environmental Engineering, applying electrochemical noise and LPR (Linear Polarisation Resistance) techniques to the testing of green inhibitors. He is now working at the DC Voltage Gradient Technology and Supply Company, which has kindly provided various research equipment for the detection (e.g., ENM) and prevention (using coatings and CP) of pipeline corrosion.

Tianyang demonstrated how the EN Bridge Method can be used to assess a number of chemical inhibitors, both green and standard, for the corrosion of steel in hydrochloric acid.

The solution acts as a conduction ‘Bridge’ in the arrangement. The cell comprises a salt bridge with two working electrodes (5 x 2 cm2 carbon steel) with a Saturated Calomel Electrode as the Reference one. Test specimens were blanked off using a Corrocoat Zip E type coating giving an exposed area of 4.5 x 1.5cm2. Specimen holders were manufactured from an ABS material using 3D printing. The stirring speed was related to the size of the stirrer, (e.g. around 300 RPM for 3 cm stirrer).

The study environments were:

• 1 % Propargyl alcohol (C3 H4 O). in 3 levels of HCl: 0.37 %, 2.6 %,

and 5.5 %.

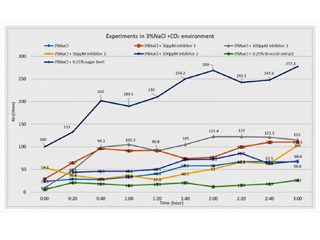

• 0.25 % Green inhibitor (Broccoli or sugar beet) in 3 % NaCl + CO2 /

2.6 % HCl, including two commercial inhibitors.

Propargyl alcohol (PA) is commonly used as an effective inhibitor in HCl solutions in the oil and gas industry. The green inhibitors were experimental test additions.

The results showed that, in Acid, PA provided significant corrosion protection (i.e. a higher Rn), especially in the highest concentration of 5.5% HCl environment. This result follows conventional theory. In 3% NaCl with CO2 bubbling through, the Rn values were found to be increasing over time, apart from when the Broccoli was added, where it actually increased corrosion compared with the control. The 100 ppm dose did better than 50 ppm for both commercial inhibitors, but surprisingly, Sugar beet showed the highest Rn value and also the biggest increase over time, suggesting potential as a green corrosion inhibitor. Comparison was made between the ENM and LPR methods using measurements on the same samples.

• ENM requires two separate iron specimens as working electrodes and one reference electrode.

• LPR measurement requires one working electrode, one reference electrode, and an additional counter electrode. It imposes an external current (±30mV) of the open circuit potential on the specimen.

In summary, the ENM approach gave comparable results to the more established Linear Polarisation Resistance (LPR) method. Further technical events are upcoming by the Aberdeen Branch, refer to Diary Dates at the rear of the magazine.

Abstracts of potential papers for the Aberdeen Technical Programme are always welcome, and anyone wishing to present should correspond with the 2024/2025 Technical Programme Co- ordinator: mei ling cheah meilingcheah@gmail.com Further Information about the Aberdeen Branch, and past presentations, may be found on their website page: Aberdeen Branch – Institute of Corrosion (icorr.org) and to join the Aberdeen Branch mailing list, please contact: icorrabz@gmail.com

CAPTIONS:

Douglas Mills, Senior Lecturer at

University of Northampton.

Left: The Electrode Arrangement is

Shown Here.

Graph Below:

All Data Obtained

Has to be Normalised by Detrending to Get the DC Potential Signature.

Different Configurations of ENM.

Measurements for a Range of Samples in Bridge and Single Substrate Arrangements of ENM and the Measurements of DC as a Comparative Method for ENM (L-R Salt Bridge, Single Substrate and DC Resistance).

Different ProCoMeter Resistances Deployed for Testing Purposes with Automated Switching of ACM Box.

The ProCoMeter Set-Up.

Various Inhibitors in 3 % NaCl + C02

Aberdeen Branch

On Tuesday 22nd August 2023 the Aberdeen Branch held its annual fund-raising Corrosion awareness Day (CAD) and welcomed eight corrosion industry speakers along with multiple equipment demonstrations from Rysco, who were ICorr’s host for this one special event. CAD is designed to assist the development of those unfamiliar with Corrosion & it’s prevention and provides and understanding of the corrosion processes and causes which are specific to a range of common industries.

Delegates learnt the basics of the role of the corrosion engineer; including materials selections, corrosion mitigations; failure investigation; testing and design issues.

Delegates – Group Photo

The Welcome was provided by the Aberdeen Branch Chair, Siji Anjorin supported by Dean Smith, Bridge of Don Operations Manager for Rysco U.K for the Safety Moment.

Rysco are headquartered in Calgary and are a global provider of Corrosion Management Solutions. They are both an ICorr Gold Sustaining Member and Aberdeen Local Branch Sponsor.

Compiled: Nigel Owen and Stephen Tate

Dean Smith, Operations Manager for Rysco U.K

A comprehensive series of Talks and Demonstrations followed the Introductions, designed to cover all they key Corrosion Topics.

1. Principles and Costs of Corrosion

Steve Paterson, Ph.D, C.Eng, Arbeadie Consultants provided the opening presentation running through the fundamentals of corrosion and electrochemistry with emphasis on what drives corrosion and the corrosion process of metals. He then outlined the different types of corrosion and common corrosion mechanisms and how these related to the Oil & Gas industry. Internal Corrosion mechanisms discussed were: Acid gas corrosion (CO2/H2S) consisting: CO2 (sweet) corrosion, Preferential weld corrosion, H2S (sour corrosion, Mixed sweet & sour corrosion), Sulphide stress cracking (SSC), Hydrogen induced corrosion (HIC), Hydrogen embrittlement, Chloride pitting/crevice corrosion, Oxygen corrosion, Microbial induced corrosion (MIC) and Sand erosion.

Several methods of corrosion control and management were outlined including:

• Materials selection: The most effective solution that can remove the corrosion threat completely (e.g. CRA/Non-metallic material).

• Water removal by dehydration.

• Chemical treatments (e.g. corrosion inhibitor, biocide or oxygen scavenger) a common mitigation method for internal protection of carbon steels.

• Use of Coatings and linings.

• Anodic/Cathodic protection used to limit and control Corrosion in both internal and external situations.

• Control of process parameters/environment, e.g. by limiting temperature and chloride content can reduce the risk of SCC.

Steve then highlighted the costs and significance of corrosion and demonstrated how implementing corrosion prevention best practices could result in savings of between 15% and 35% with the NACE 2016 study quoting savings of 3.4% of global GDP (Gross Domestic Product), giving immense motivation for corrosion engineers to contribute in achieving such savings and associated improvements in integrity of infrastructure and protection of the environment

2. Materials Selection

Rob Howard, PhD, of Lloyd’s Register discussed materials selection critical to the Oil & Gas processing industry making reference to a process diagram from well to final product, he looked at the common types of corrosion witnessed in the process equipment: A selection of materials for corrosion resistance was reviewed showing how we can move from Martensitic and Austenitic Stainless steels up to Duplex and onto Ni and Titanium alloys to get sufficient resilience, albeit with some heavy cost implications.

Rob Howard graduated with a in Materials Engineering from the University of Cape Town in 1995. and worked as a post-doctoral researcher at the Corrosion and Protection Centre, University of Manchester. He joined Lloyd’s Register in 1998 and at present he is the team leader for the Offshore Materials team in LR, whose main function is to provide technical support to surveyors and clients and to review design specifications for oil and gas and offshore wind projects.

He explained how the choice of equipment materials is influenced by parameters such as corrosivity, flowrates and chloride and hydrogen sulphide levels. However, equally important are the heat treatment condition and mechanical properties required, the corrosion resistance and issues such as weldability and ongoing costs for inspection maintenance and repair of materials selected. Rob referenced a number of international sources which are particularly useful for materials selection and stressed the need to examine Manufacturer capability and quality control of the product:

• Norsok M-001 (edition 5, Sept 2014)

• ISO 21457

• ISO 15156 (NACE MR-0175)

3. Oilfield Microbiology Analysis and Data Trending

Carol Devine, PhD, BSc (Hons) of NICMB has over twenty-five years’ experience in oilfield microbiology. She has a particular interest in microbiologically influenced corrosion (MIC), sulphate-reducing bacteria (SRB), seawater injection systems and molecular microbial ecology in general. NCIMB preserve, store and supply a collection of cultures to industry and universities with the largest collection of industrial, marine and food bacteria in the UK and have approx. 10,000 strains; 300 genera; 2000 species – and still growing.

Oilfield equipment is commonly damaged by the presence and activity of micro-organisms in systems for Production, Seawater Cooling, Water Injection, Cooling/Heating and in handling of Produced Water, Firewater, reinjection (PWRI), Diesel Storage & Ballast Water. The Organisms are either Planktonic from bulk water phases or Sessile biofilms on surfaces.

Carol explained the role of the oilfield microbiologist in generating useful and appropriate data in order to:

• Predict which particular systems, vessels, pipelines, locations are under threat from microbiologically influenced corrosion (MIC)

• Prioritise areas for treatment according to budget and time available

• Apply and monitor appropriate strategies to mitigate against the effects of MIC or biofouling

Techniques for analysis where explained: Triplicate MPN’s, qPCR and Metagenomic Analysis (NGS) to assess the threat of MIC and to quantify, identify and assess the activity which needs to be monitored on a continuous basis to see trends from production changes and implement actions to control and prevent system infestation which affects flow and efficiency in the process.

4. Corrosion Mitigation by Cathodic Protection

Dr. Nigel Owen, B.Sc., D.I.C, Ph.D., MIMMM, MICorr, Aberdeen Foundries has worked in the Aluminium Industry for over 35 years on alloy development and manufacturing processes, spending his later years at Aberdeen Foundries as Sales, Technical and Plant Manager, manufacturing Sacrificial Anodes He now oversees manufacturing, testing and design of all subsea and marine sacrificial anode systems.

Nigel explained how the Galvanic table shows naturally what materials are suitable as bases for sacrificial anodes. Aluminium, Zinc and Magnesium being the primary common bases for development of the alloys. With a sufficiently electronegative potential the base material can be alloyed with other elements to make it more electronegative and efficient as an anode. Aluminium has a high current output per Kg consumed and therefore has become the material of choice for anodes, particularly on large structures.

His presentation covered:

• Alloys for Sacrificial Anodes

• Design of a CP system to protect a structure

• Applications of Anodes

• The selection of the CP system:

• The pro’s and con’s of Sacrificial and Impressed systems and their applications.

The process of designing of a sacrificial anode system was explained from assessment of (cathode) material areas and the effect of coating to the calculation of anode mass and current output for a structure in an immersed environment.

Comparison was made between Sacrificial and impressed current systems in terms of their benefits or advantages in given current demand situations and maintenance requirements. Performance being determined by the conductivity (salinity) and the temperature (water depth/ geographic region) of deployment.

5. Corrosion Mitigation by Coatings

Colin Thomson HND, FM Lead at Bilfinger Salamis, has over 20years experience working in oil and gas fabric maintenance after serving in the Merchant Navy. He has supported various clients FM requirements including, BP, and Conoco Phillips, ExxonMobil and Petrofac. He skilfully explained how Fabric Maintenance prevents corrosion, degradation and wear which could otherwise lead to safety and or operational issues. Coatings acts as a barrier to the environment therefore all locations where coatings are damaged must be maintained to prevent metal loss. Colin also brought everyone up to date with modern FM strategies and also instantaneous barrier methods such as anti-corrosion tapes (ACTs) and Corrosion Inhibiting Waxes.

Various key properties of coatings were highlighted including:

• Anti-Fouling

• Environmental Protection

• Fire Protection

• Process Flow aids.

• Safety

• Thermal protection / insulation

The complete range of surface preparation techniques were evaluated along with all factors affecting coating ‘Life Expectancy’ for example:

• Anchor Pattern (too rough or too smooth)

• Chemical Salts

• Condensation

• Existing Coatings

• Fabrication Defects (weld spatter, sharp edges)

• Mill Scale

• Oil, grease and soil

• Surface Corrosion

6. Corrosion and Chemicals Management

Jennifer Watson HNC, Senior Account Manager/Production Chemist at Champion X is currently based within the BP office supporting Glen Lyon FPSO and has over 20 years experience in Oil & Gas operations offshore and onshore. She enthusiastically described all the key chemical mitigations deployed within the energy sector including:

• Biocides for preventing MIC

• Corrosion inhibitors for internal corrosion

• Drag reduction

• Oxygen and H2S scavengers pH stabilization

Jen also discussed all commonly used monitoring processes and analysis methods for rates, chemical residuals and other dosing checks. Most importantly she emphasised the need for having appropriate Chemical & Corrosion Control Matrices (CCCM) in place. These are the basis for understanding individual threats and how they should be mitigated by applied chemical application or other barriers.

A magnificent Lunch followed with an opportunity for all to network.

One of many Networking Opportunities.

7. Integrity Management and Risk Based Inspection.

Simon Hurst, BSc, MSc has been with CAN since 2008 and is currently the Engineering Director where he is responsible for the ENGTEQ business stream and is the nominated Technical Manager under their UKAS Accreditation for Integrity Management and Pressure Systems Inspection. He commenced his talk by defining Integrity Management – BS ISO 55000:2014 states that it enables an organization to achieve its objectives through the effective and efficient management of its assets. The application of an asset management system provides assurance that those objectives can be achieved consistently and sustainably over time.

Simon went on to define some of the key components of Asset Integrity Management including the following:

• Ageing and Life Extension

• Anomaly Management

• Corrosion Control Matrices

• Failure Investigations

• Integrity Operating Windows

• Risk Based Assessments leading to Risk Based Inspection

He then defined with good detail the nature of risk and the various different methodologies for Risk Based Assessment. In relation to CRA’s Simon usefully highlighted that:

• Although the use of corrosion resistant alloys generally leads to an increase in the time between inspections, the subsequent inspection of those CRAs is normally significantly more problematic than say on Carbon Steel.

• The use of CRAs (v CS) doesn’t normally lead to a significant increase in the periodicity for the first in-service inspection as this is more about identifying fabrication type defects than in-service damage.

In closing he reminded Delegates that it is best practice to create a “Written Scheme of Examination” (WSE) that details the applicable degradation mechanisms, and the precise location and inspection technique that will be used in order to try and either find the mechanism or confirm its absence.

8. Corrosion and Erosion Monitoring

Dean Smith is an experienced Operations Manager in the Corrosion Monitoring industry, having started his career as a Retrievals Technician in 2007 and worked his way up to field services management and eventually operations management. He emphasised that erosion and corrosion pose significant challenges to oil and gas production, impacting safety, efficiency, and profitability and effective monitoring techniques, combined with ongoing innovation and investment, are essential to mitigate these challenges and ensure the sustainability of the industry.

Prior to the practical demonstrations, Dean gave a run-through of the key services of Rysco UK which cover the following:

Design & Supply of Internal Corrosion Monitoring Systems including: High & Low Pressure Access Systems:

• Custom Equipment Design & Manufacturing

• Electronic Monitoring, e.g., Electrical Resistance Instruments

• Injection & Sampling Systems

• Mechanical Monitoring, e.g., Corrosion Coupons

Field Services including: High and Low Pressure Monitoring Device Retrieval.

• Hot Tapping

• Monitoring Data Analysis and Reporting

• Monitoring System Audits

• Sampling and Lab Analysis

Online Reporting including: Custom Reporting Dashboards via Business intelligence Software and Interactive Mapping

Sponsor’s Process Equipment Demonstrations

Three separate demonstrations followed for which the 52 strong gathering was split into 3 rotating groups.

Richard Rae of Rysco U.K explains Integrated Corrosion Data Management

Retrieval Tool Demonstration

Corrosion Coupon Review

A Corrosion Quiz covering multiple aspects of the Speaker Presentations followed by a vote of thanks from the President and CPD awards closed this very successful event attended by over 50 delegates.

Delegates enjoying the Corrosion Quiz

ICorr Aberdeen welcomes suggestions for further Industrial visits.

Abstracts of potential papers for the Aberdeen Technical Programme are always welcome, and anyone wishing to join committee should correspond with the 2023/2024 Technical Programme Co-ordinator: Adesiji Anjorin anjorin@gmail.com

Further Information about the Aberdeen Branch, and past presentations, may be found on their website page: Aberdeen Branch – Institute of Corrosion (icorr.org), and to join the Aberdeen Branch mailing list, please contact: icorrabz@gmail.com

Aberdeen Branch

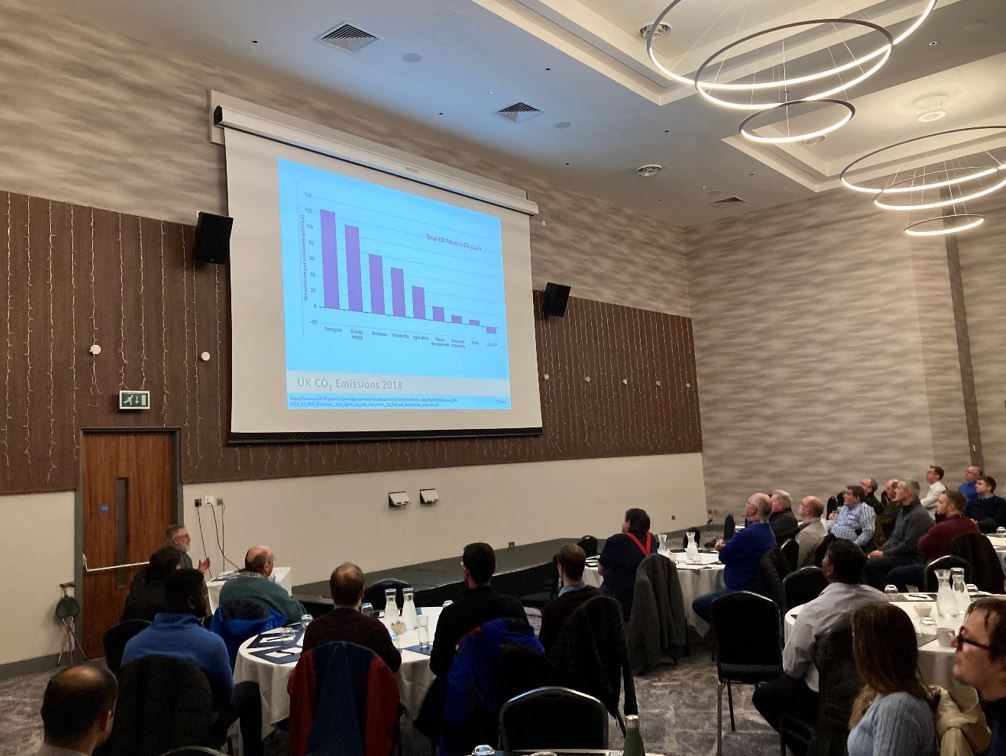

ICorr join forces with IMechE for a special Pre-Christmas Celebration.

On 20th December 2023, the Aberdeen ICorr Branch were guests of IMechE for a Joint Event at the Sandman Hotel in Aberdeen. This end of year Celebration that was very well attended with around 60 guests and was chaired by Steve Cromar CEng, FIMechE, IMechE Aberdeen Chair. The evening commenced with a welcome Hot Buffet Dinner, which was an excellent choice for a cold Winter night.

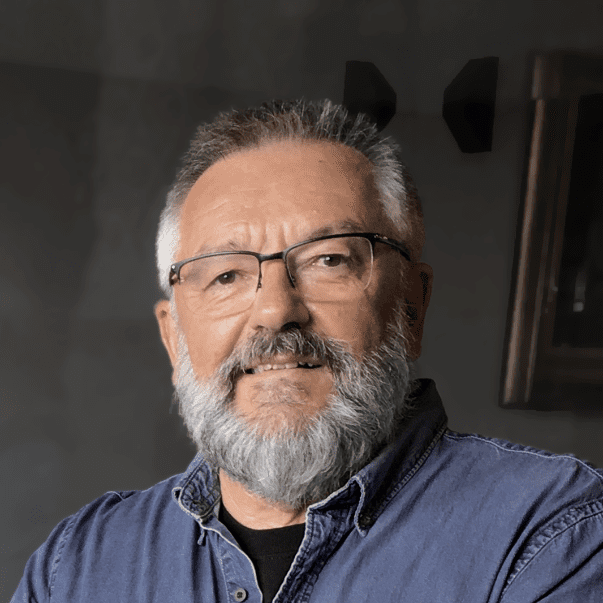

Tom Baxter a Chemical Engineering Consultant and founding member of the Hydrogen Science Coalition spoke on ‘Future Energies and Greenhouse Gas Reduction’.

Tom Baxter BSc (Hons), FIChemE

Tom graduated from Strathclyde University in 1975 with a B.Sc. in Chemical Engineering (first class honours) and is a Fellow of the IChemE. He started his career with ICI Petrochemicals, moved to fine chemicals with the Swiss company Ciba-Geigy before taking a position as a Process Engineer in 1980 with BNOC (British National Oil Corporation). Through privatisation and acquisitions BNOC became Britoil, then BP. Here he worked as an Operations Engineer, Development Engineer and Research Manager. In 1991 he left BP subsequently held positions with Altra Consultants as Technical Manager, as Technical Director with Genesis in 1998 and became the Aberdeen Business Unit Director in 2005. From 2010 together with became a Senior Fellow in the Chemical Engineering Department at Aberdeen University, which he helped establish and since 2003 he has been a visiting Professor of Chemical Engineering at Strathclyde University.

This coming decade is extremely important for achieving reductions and Individual impacts are great. During his most interesting talk key themes discussed were ways to use less energy and an eye-opening debate on the misconceptions about renewable alternatives, (in terms of actual energy efficiency breakdown from production through to final distribution) which was considered in great detail. Overall electrification came out as a very safe and efficient energy source.

Industrial Hydrogen Use

Hydrogen (H2) does have some favourable characteristics – particularly buoyancy and no carbon monoxide but has low caloric value. Generally, Hydrogen compares unfavourably overall with Methane properties and has limited applications presently. For example, it requires three times the amount of compression power to move it along pipelines and much talked of blending Hydrogen was not seen as a good idea although a 20% blend has much promoted of late by others presenting to the Institute.

H2 is considered applicable for Transport (although passenger car-dominated) and for some specialised industries e.g. steel making. There have been recent question marks over some H2 driven projects. Pau (in France) cancelled its H2 buses and the Redcar hydrogen project was recently cancelled.

Full electric vehicles are seen as most energy efficient, for trains only low train passenger routes in the UK (8ookms out of 15000 kms) but there are lots of Hydrogen miscellaneous uses, but batteries are the key to the future progression of renewables. Presently the accurate Hydrogen retail cost is not clearly defined.

Tom Baxter (seated) Chemical Engineering Consultant and Hydrogen Expert presented.

Tom also spoke of https://www.h100fife.co.uk/ a parliamentary party group with interests including Cadent / Shell / others – Projected costs to 2050 however are not considered reliable.

Domestic Hydrogen Use

Vested interests e.g. Catapult and EUA have recently promoted Hydrogen for heating. Tom reviewed the outcomes of hy4heat – Hy4Heat Its mission was to establish if it was technically possible, safe and convenient to replace natural gas (methane) with hydrogen in residential and commercial buildings.

Through a QRA study, they found that Hydrogen was inherently less safe than Methane QRA with three times as many potential events. Hydrogen usage requires more safety features and is 40% less energy efficient overall. Electric energy provides greater wattage.

Summary

Generally, with renewables, more government support is needed, so as to give more headroom / opportunity to recover capital cost over a longer period.

Tom Baxter was extremely knowledgeable and provided a most interesting talk.

Refer www.h2sciencecoalition.com

Hydrogen Science Coalition | Bringing an evidence based viewpoint into the political discussion on hydrogen (h2sciencecoalition.com)

Members of the Aberdeen ICorr Committee, with new member Stephanie Okoye 2nd from Left, with guest Shukun Liu (Oceaneering) far right.

Q&A

A lively Q&A followed:

- Will Hydrogen deliver in the short term? – No. Tom was of the view that the UK government was without a proper energy strategy and unfortunately its politicians are mostly not Stem educated (only about 10%) and therefore don’t ask right questions when dealing with potential energy providers.

- How do we manage the Stakeholders for H2 development? – Tom felt that key policy must come from Government but they must understand all the issues.

- How can we educate local communities properly about energy and renewables? – Tom proposed that Engineering Institutions like IMechE and ICorr are best placed to provide reliable information to the public.

Future Meetings

The Aberdeen Branch of ICorr hopes to continue its relationship with IMechE during the next Technical Session 2024-2025

IMechE Aberdeen meet on the third Wednesday of each month and may be contacted at:

Contact the Aberdeen Area – Institution of Mechanical Engineers (imeche.org)

ICorr Aberdeen meet on the last Tuesday of each month and may be contacted at:

icorrabz@googlegroups.com

Aberdeen Branch

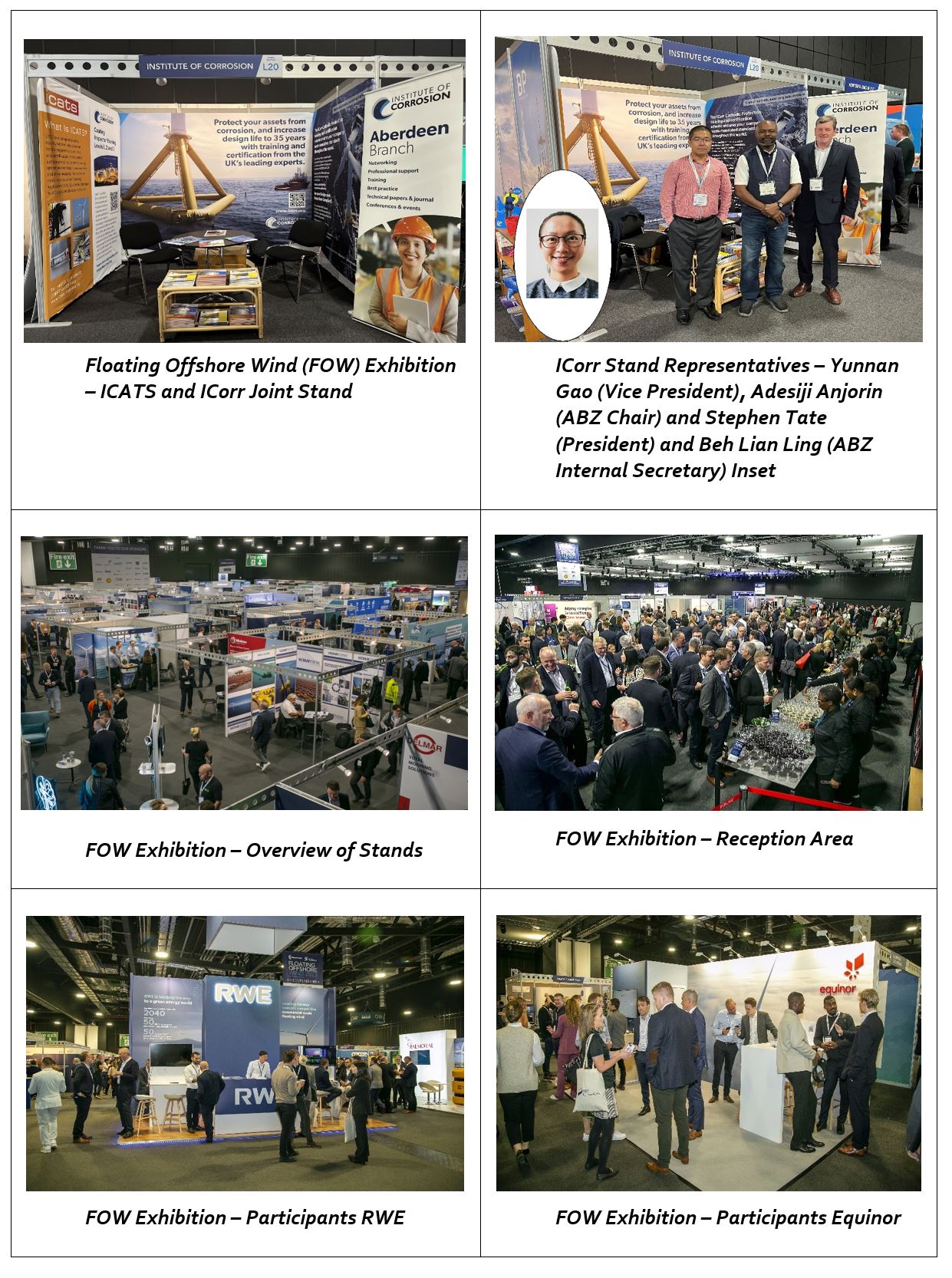

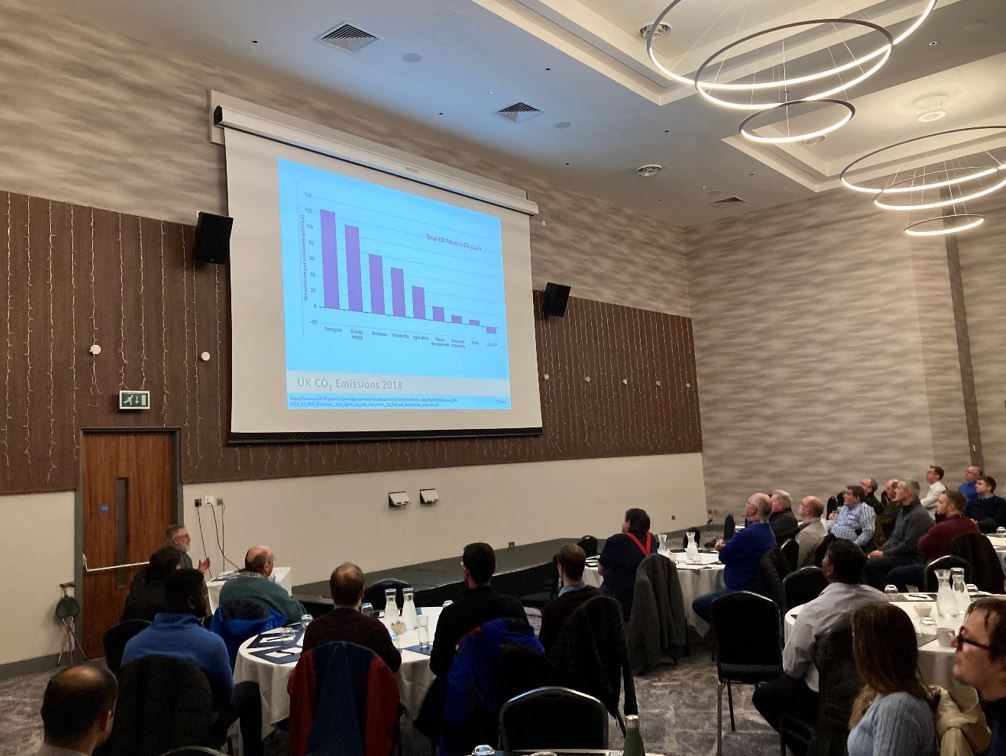

Initiated by Council and CP Governing Board member Bryan Wyatt, the Institute exhibited at Floating Offshore Wind (FOW) Expo 2023 (Conference & Exhibition) on the 4th and 5th of October 2023.

This unique operator and service provider event comprised around 100 Speakers, 200 Exhibitors and 2000+ high level attendees from around the globe.

ICorr Council and CP Governing Board member Bryan Wyatt (seen presenting at CEOCOR)

FOW is the meeting place for all the current and future players in the global floating wind industry. Providing an unrivalled opportunity to meet and network with all the key players as well as discuss the key technical challenges and solutions surrounding the industrialisation and commercialisation of floating wind.

ICorr’s participation was very successfully handled by the Aberdeen Branch and attracted a wide range of stand visitors. The key focus for this Event was our Training Services – Industrial Coating Applicator Scheme (ICATS) and ICorr’s Cathodic Protection and Coating Inspector courses that promote independent reporting to Facility Owners, (as now required in DNV-RP-B401 for their Cat IV coating). The highest levels of Competency, Specification and Performance Assessment at all stages from Design onwards are essential to maximise FOW Equipment life with Operators now seeking up to 35yr lifespans.

In the Cathodic Protection World, initial FOW structures were designed to RP-B401 which provides good guidance for conventional fixed jackets but is considered inadequate for monopiles or floating turbines. Latest available standards however, (the improved) RP-B401 and (the new) ISO 24656 require design by a competent, experienced CP Engineer/Expert (and Level 4 certification is the best measure, noted on both DNV and ISO).

One of the Key Objectives of our participation was to help drive Quality throughout the FOW Industry.

ICATS and ICorr’s presence at the Expo resulted in more than 60 high quality leads and around half of these were enquiries related to our existing –‘Training Services’ and others requesting new courses specifically covering the updated RP-B401 – 2021 and (the new) ISO 24656 – 2022 standards.

The Event provided excellent FOW Industry engagement and neatly followed our very well attended North-East branch sustainability conference. North East Branch – Institute of Corrosion (icorr.org) refer Local Technical Programme – 2023 Presentations.

![]()