The cart is empty!

Innovative Corrosion Under Insulation Training Breaks New Ground

Experience Shared and Expertise Qualified

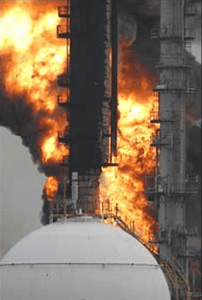

Corrosion under insulation (CUI) remains a challenging corrosion mechanism to manage across the global process industries. After 70 years of insulating equipment and numerous published guidance, CUI failures continue to occur – some with very high safety, finance, and environmental consequences. CUI occurs on insulated, carbon steel, low-alloy steel, and stainless-steel equipment across a wide range of operating temperatures and coating and insulation designs. CUI can be especially prone to catastrophic failures.

While there are several CUI training courses available, few address the holistic nature of corrosion under insulation based on plant experience, and few include the examination that certifies the expertise that attendees have acquired. Industry is left without a recognised standard for companies, employees, contractors, and consultants who must manage design, risk assessment, and detection strategies of CUI, to reduce the onset and severity of CUI and detect significant CUI before failures occur.

The Institute of Corrosion has addressed this by developing an ICorr-accredited CUI course that includes examination and certification.

In this article, we answer the following key questions:

- What makes this a must-attend course?

- Who should attend the course?

- What can you expect to learn?

- Why should you attend this course?

What makes this a must-attend course?

Certification – not just of attendance but of your new knowledge and acquired expertise – is a crucial and defining element of this course. However, that’s not all that makes this training so exceptional. The credentials behind this two-day course are impeccable.

You may recognise the two names that have shaped the content of, and present the ICorr-CUI course:

With 25 years’ experience in corrosion and integrity management, Clare Watt has set up and led CUI improvement campaigns, created CUI risk-based control methods, and conducted work in CUI data-driven innovation, among many other accomplishments. Clare is one of a small group of people who have specialised in CUI, having worked for a well-known global insulation and coatings service provider for six years to develop CUI expertise and innovation.

With previous experience across different oil and gas operators, service providers and assets, including ExxonMobil corrosion subject matter expert and consultancy to many other operators, Clare has specialised in operational integrity improvement programs, failure investigation, and problem solving; for 15 years she delivered the industry corrosion lecture for the Cranfield University Corrosion Training Program.

Dr Steve Paterson has more than 40 years’ experience and has built an eye-popping CV. His work has taken him around the globe, encompassing materials, corrosion, and welding inspection.

While Discipline Head for Shell’s European Upstream Assets, Steve’s responsibilities included involvement with CUI integrity issues. This included investigating significant failures, and executing major refurbishment programmes.

Though he officially retired in 2017, Steve’s involvement with the corrosion industry never stopped. He has remained active as a consultant on many corrosion management projects. He’s specialised in wider corrosion training including materials and corrosion in well engineering, stress corrosion cracking, and insulation inspector training, as well as CUI.

Dr Paterson was the recipient of the Paul McIntyre Award 2019 for his services to the corrosion protection industry.

In short, when attending ICorr’s Corrosion Under Insulation course, the expertise you onboard is gained directly from more than 60 years of corrosion industry experience, from two lead engineers with extensive knowledge of corrosion under insulation.

Who should attend the course?

This two-day course and the certification with it is ideal for all those who wish to improve their knowledge and capability in the CUI field.

If you slot into any of the following job descriptions, this corrosion under insulation training could prove invaluable to your career:

- Managers and engineers with responsibility for design and operation of safe and reliable fireproofed pressure systems

- Mechanical, projects, and operations personnel

- Repair and maintenance technicians who deal with plant pipework, pipelines, and vessels

- Process engineers

- Coatings inspectors

- Coatings installers

- Manufacturers of insulation equipment and materials

- Anyone with responsibility for the integrity and inspection of plant and installations

This training is relevant for companies of all sizes, existing and new builds, including in the oil and gas industry, upstream, onshore and offshore, petrochemical, and LNG.

What can you expect to learn?

Don’t be fooled by the duration of this course. We know your time is precious, and so it benefits from fast-paced delivery, keeping you engaged with both theory and practical examples and exercises. You’ll also have direct access to the trainers for their support and answer all your questions.

You’ll receive a complete CUI overview applicable to all levels of experience. The presenters will address your queries with their own real-life experiences, a vast library of case studies, and their extensive CUI knowledge networks. This course is bang up to date and will impart the latest developments and innovation work to deliver a much-needed step-change improvement in efficient and effective CUI management.

You’ll love the interactive nature of learning on this CUI training experience. The enthusiasm that Clare and Steve have for imparting their experience and knowledge is infectious – and you’ll get a huge amount of course materials and documentation to help you toward successful certification and beyond.

As a summary of the modular course content, training covers:

· An overview of CUI

Introducing you to CUI with specific examples of failures, lessons learned, and challenges faced.

· Influencers of CUI and the CUI mechanisms

Discover the mechanism of CUI, the environmental factors that cause it, and what we can and cannot control.

· Design considerations for insulation systems

Standards to follow in the design of insulation systems, including different types of coating, insulation, cladding, water management design features, and installation quality considerations.

· CUI management

This includes how to build risk assessment methods to set inspection and coating repair strategies and the need for insulation, relating to the latest design, prediction, and inspection technologies. You’ll learn about the extent and origin of CUI prediction knowledge, and how to avoid common errors or weaknesses that have led to serious failures.

· Non-destructive CUI detection techniques

Non-destructive inspection technology can play a significant role in CUI management. You’ll be introduced to a range of NDE technologies, their capabilities, and current NDE innovation projects.

· Monitoring systems

An introduction to permanently installed monitoring systems, old and new generation technologies, including remote digital sensors, and current sensor innovation status.

· Challenges in adopting CUI technology

A discussion of the key challenges faced in adopting state-of-the-art technologies, whether design, prediction, detection, or monitoring, and how these challenges are currently being addressed on a global level.

No questions unanswered

With interactive case study sessions, and time set aside for feedback and Q&As at the end of each day, you’ll never be left with an unanswered query. The course presenters also encourage you to bring your own case study for review.

Why should you attend this course?

At the Institute of Corrosion, we have noticed a general trend within the industry toward requiring certified expertise. Industry, governing bodies, and companies are increasingly concerned with the quality of the employees, contractors, and consultants they hire.

Like our PFP training (and other ICorr-accredited corrosion courses), the certification and qualification you receive from this course upon passing the exam will confirm your competency within the field of CUI. The knowledge you receive will enable you to make informed choices. Should such competency be mandated (which we expect it will be in the future), you’ll be ahead of the game.

To learn more about the course details and how to pre-register, contact our ICorr admin department.

STOP PRESS!

We’re offering a special course price to those who register on our first CUI Practitioner Course (date of course below), as part of our focus on World Corrosion Day. Here are the details you need:

Date of Course: Tuesday 8th and Wednesday 9th October 2024. (Lunch, tea, and coffee are provided.)

Location: ICorr HQ, Corrosion House, 5 St. Peter’s Gardens, Northampton, NN1 1SX, UK.

Cost:

- £1,800 without examination – a certificate of attendance will be provided

- £1,900 including examination – if passed, you will qualify for the CUI Practitioner Certificate

This represents a 20% reduction on the standard course price, but this price is only available for the October course.

Don’t miss out on this one-off discount. To book your place on the course, contact our ICorr admin department today.