Institute News

The new Wales and South West of England regional branch held its first event in Southampton on 24th October 2024. The event was held at Lloyd’s Register/Lloyd’s Register Global Technology Centre with presentations from Dr Maryam Bonyadi and

Dr James Kwame, both from Lloyd’s Register (LR).

Dr Maryam Bonyadi is a Technical and Failure Investigation Senior Specialist at LR. The presentation provided an introduction to LR and the specialist services LR provides. The presentation also included an overview of the LR’s Technical and Failure Investigation Department, its team, locations and some of the capabilities. Further, examples of corrosion mechanisms commonly found in the maritime industry were presented.

The second presentation was by Dr James Kwame, who is the Senior Manufacturing Technologist at Lloyd’s Register, working to develop LR’s internal and external technical publications. The presentation provided an insight into liquified CO2 and the impact of impurities such as H2O, O2, SO2, H2S, NO2 and organics which may be present in the CO2 stream on corrosion and phase change. The talk explored current industry limitations and the general lack of standardisation governing product specifications, such as the quality of CO2 grades, which present significant challenges in understanding their effect on corrosion and phase change during ship transportation and storage.

The talks gained lots of engagement and interaction from the audience, with many questions and plenty of further discussion. With 20 delegates in attendance, the first Southampton event was deemed a successful one!

Upcoming Event:

The next branch event will take place online on

December 11th 2024. For more information,

contact swchair@icorr.org

You can also keep up to date on events by

visiting our LinkedIn page;

https://www.linkedin.com/groups/12992293/

Dr Maryam Bonyadi is a Technical and Failure Investigation Senior Specialist at LR. The presentation provided an introduction to LR and the specialist services LR provides. The presentation also included an overview of the LR’s Technical and Failure Investigation Department, its team, locations and some of the capabilities. Further, examples of corrosion mechanisms commonly found in the maritime industry were presented.

The second presentation was by Dr James Kwame, who is the Senior Manufacturing Technologist at Lloyd’s Register, working to develop LR’s internal and external technical publications. The presentation provided an insight into liquified CO2 and the impact of impurities such as H2O, O2, SO2, H2S, NO2 and organics which may be present in the CO2 stream on corrosion and phase change. The talk explored current industry limitations and the general lack of standardisation governing product specifications, such as the quality of CO2 grades, which present significant challenges in understanding their effect on corrosion and phase change during ship transportation and storage.

The talks gained lots of engagement and interaction from the audience, with many questions and plenty of further discussion. With 20 delegates in attendance, the first Southampton event was deemed a successful one!

Upcoming Event:

The next branch event will take place online on

December 11th 2024. For more information,

contact swchair@icorr.org

You can also keep up to date on events by

visiting our LinkedIn page;

https://www.linkedin.com/groups/12992293/

Photo: Delegates Observing the Presentation by Dr Maryam Bonyadi.

Photo: Delegates Observing the Presentation by Dr James Kwame.

Institute News

NW Branch held their AGM on 1st October 2024 at the Luther King House Conference

Centre. Representatives from industry and academic research heard from two excellent speakers, Dr Patricia Conder from ESR Technology and Dr Paul Lambert of Mott MacDonald.

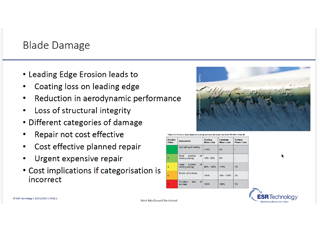

Patricia presented on the topic of “Non-Destructive Testing Challenges in the Net Zero World,” covering the challenges of inspecting and testing assets in relation to carbon capture and offshore wind. Conversion of existing assets to process hydrogen and carbon dioxide and testing for the associated changes in degradation mechanisms were some of the many highlights.

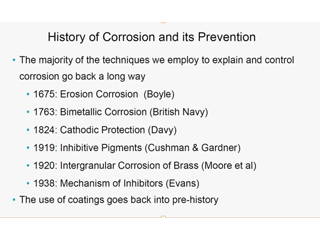

Paul Lambert covered the 200-year anniversary of cathodic protection since its conceptualisation at the Royal Society by Humphry Davy in 1824. The patenting of Portland Cement by Joseph Aspdin, also 200 years ago (!) was also touched upon in an excellent and enlightening presentation.

Both presentations can be found on the NW Branch Website – www.icorr.org/northwest/ at Local Technical Programme, along with previous presentations for what has been an excellent year for ICorr NW.

Our New Honorary Secretary

Brenda has been a long-standing member of the Institute and North-West Branch for over 30 years and has served in several important positions and is now the Honorary Secretary of ICorr and a new Trustee. She has been a consultant scientist for 40 years and has acted as an expert for the defence in criminal trials. Brenda is also an RAC-appointed independent inspecting engineer for vehicle paintwork and consultant to the Road Haulage Association. We wish her the very best as she takes over the role of secretary for ICorr nationally.

Photo. Dr Patricia Conder Delivering Her Presentation.

Photos: Slides from Patricia Conder’s Presentation.

Photos: Slides from Dr Paul Lambert’s Presentation.

Photo. Brenda Peters our New Honorary Secretary

Our New Committee Members

New members with a wealth of academic experience have now joined the committee in the form of Vincenzo Bongiorno and Alyshia Keogh. We look forward to the continued growth of the branch and more successful events next year.

Vincenzo is a research associate at the University of Manchester, where he has been recently awarded his PhD in Materials Science. His research focuses on organic coatings for corrosion protection, electrochemistry, and the interpretation of the electrochemistry of corroding systems with artificial intelligence.

Before starting his PhD, Vincenzo got his bachelor’s and master’s degrees in chemical engineering at the University of Palermo and worked as a materials engineer at Solvay Speciality Polymers.

When he is not too busy in the lab, Vincenzo loves walking/hiking (when it’s not too rainy), reading and writing, and playing guitar.

Alyshia Keogh is soon due to complete a PhD at the University of Manchester in metallurgy and corrosion. Her research has focused on the effect of microstructure on the localised corrosion behaviour of stainless steel for aerospace applications. Alyshia holds a Masters’ degree in Materials Engineering from the University of Sheffield and has previously worked in the heat treatment and manufacturing industries. She has participated actively in ICorr this year through her enrolment on the Young Engineer’s Programme. Aside from her interest in corrosion, Alyshia enjoys running, cooking, live music, and spending time with her cat.

Upcoming Events:

For future events please visit: www.icorr.org/events/

If you wish to present, please contact: nwchair@icorr.org

Photo: Vincenzo Bongiorno, University of Manchester.

Photo: Alyshia Keogh, University of Manchester.

Institute News

By Dr Prafull Sharma (Interim Chair, Midland’s Branch)

Our Year to Date

2024 has been a year of reforming and progress for the ICORR Midlands Branch. The branch, under new leadership of Dr Prafull Sharma, has embarked on initiatives to enhance its activities and strengthen member engagement. One key area of focus has been regional outreach, particularly to universities, aiming to encourage young professionals

to join ICORR and contribute to its growing community. Plans are also underway to further develop physical and digital engagement, combining events with an intensified presence on online platforms.

The branch’s digital initiatives have shown remarkable success. The ICorr LinkedIn channel, launched just a few months ago, has quickly surpassed 1,000 followers and continues to grow. This platform has become a vital resource for updates, educational content, and community interaction, and we encourage all members to follow it for the latest news. Expanding on this, the branch also launched a YouTube channel this year.

This will serve as a repository for all future webinars and educational resources, making them accessible to a broader audience. Members and followers can now revisit valuable sessions or catch up on missed events at their convenience.

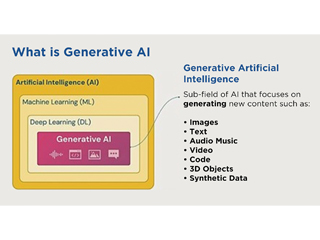

In addition to these digital advancements, on 19th June 2024 the branch has previously hosted a well-received webinar on Generative AI for Corrosion Professionals. This session, attended by over 200 members, explored the applications of artificial intelligence in addressing corrosion challenges, providing attendees with insights into the potential of AI to transform the field. The success of this event has reaffirmed the importance of delivering high-quality, innovative content to members and has inspired plans for several webinars in 2025. Refer to: www.icorr.org/midlands/Local Technical Programme – 2024 Presentations.

A mini-conference is proposed for 2025, with dates to be announced soon. The conference will bring together industry professionals, researchers, and academics to discuss current trends, challenges, and innovations in corrosion science. Meanwhile, the branch is also collaborating with the Marine Corrosion Forum (MCF) to organise a joint event in April 2025, reflecting a strengthened partnership and a commitment to fostering broader industry collaboration.

Engagement with MCF has been another highlight of the year, exchanging ideas and building connections to enhance ICorr’s impact. This collaboration underlines the branch’s mission to foster partnerships that amplify the reach and value of its activities.

As we move forward, ICorr Midlands remains dedicated to creating a dynamic, inclusive platform for knowledge sharing and professional development. With plans for innovative digital content, impactful events, and strategic collaborations, the branch is well-prepared to deliver value to its members while advancing the corrosion profession. We thank all ICorr members for their continued support and look forward to your continued engagement in the coming year.

Upcoming Branch Events

For future events please visit: www.icorr.org/events/

If you wish to present, please contact: midlandschair@icorr.org

Photo: Dr Prafull Sharma,

Interim Chair, Midland’s Branch.

Photo: Midlands Webinar – Generative AI for Corrosion Professionals.

Institute News

On 10th October 2024 the branch held a joint meeting with the London Materials Society

(LMS), when Ali Morshed presented, “Why Effective MIC Control is Still a Major Challenge in the Industry.”

Ali has a PhD in corrosion engineering from University College London and is the author of five corrosion management books, and one book on MIC, with NACE/AMPP. He is a corrosion engineer with more than 21 years of experience, starting his career in the Oil and Gas industry in 2002, and gradually expanded his work to many other industries.

Microbiologically influenced corrosion (MIC) remains as a major integrity threat and cause of failure for many upstream, mid-stream, and downstream, oil and gas assets, despite the continuous technological advances in the areas of oilfield microbiology, metallurgy, and chemicals.

MIC can be defined as corrosion influenced by the presence, or activity, of microorganisms. Such microorganisms can cause corrosion problems for various oil and gas assets either directly or indirectly. The corrosion damage inflicted by them is considered direct when they create, or further increase, the environment’s corrosivity (e.g., by acid production through their metabolism). The damage is considered indirect when they attack, deteriorate, or weaken, a corrosion control measure already in place, thus further promoting corrosion. Such affected corrosion control measures include surface coatings and some corrosion control chemicals such as certain types of oxygen scavengers.

Ali explained that the locations or systems most susceptible to bacterial contamination and MIC include, but are not limited to, sea water injection, fire water, cooling water, sand-wash water (where treated sea water is used to wash the sand accumulated in various pressure vessels), water displacement systems (where treated sea water is used to empty a product storage tank), and wet product transfer pipelines and product storage tanks.

He highlighted an important caveat regarding MIC – prevention is always better than cure, because microbial control once lost, may take years to restore, if at all! Extensive field experience from both the UK’s North Sea sector and the Persian Gulf r

egion indicated that the main root cause of the encountered MIC leaks, failures, and issues, has been either the total lack,

of or inadequate, knowledge and expertise in relation to bacterial and MIC basics and fundamentals, among the

relevant personnel.

More precisely, MIC incompetency has been the main culprit behind the failures. In general, the observed MIC incompetency can be divided into the following subject areas:

- Bacterial nourishment and growth conditions

- Bacterial and MIC monitoring

- Bacterial and MIC assessment and control

The last two items, when combined comprise the overall bacterial and MIC mitigation process, as was mentioned earlier.Simultaneously, it has also been observed that Oil and Gas assets which successfully managed and controlled the MIC integrity threat were those where the relevant personnel possessed adequate MIC competency, mainly due to the MIC training they had received.

Ali finished by saying that while MIC incompetency remains the main root cause of bacterial and MIC problems, timely, practical, and adequate MIC training is regarded as the main solution, and way forward for tackling the existing MIC issues for the Oil and Gas assets concerned.

Photo. The chair for the Evening Introducing the Speaker and the LMS Vice Chair, Melissa Tiskaya.

Photo. Ali Morshed Presenting on MIC.

Photo (Right): After an Interesting Q&A Session, Ali was Presented with an ICorr Pen in Appreciation of His Talk, by the Chair for the Evening, ICorr Committee Member, Brian Goldie.

The London Branch also kindly hosted the 2024 Young Engineers (Case Study) Programme reported separately above on page 10.

Institute News

ICorr Aberdeen Updates

On Thursday 7th November 2024 the Aberdeen Branch in a joint meeting with TWI welcomed Dr. Cheng Huan Zhong of Inductosense Limited, with a talk entitled ‘A Pathway to Thickness Measurement Locations (TMLs) Digitalisation.’

Complimentary to the recent presentation to South-West Branch by Erik Fabre this event focussed specifically on Case Studies of Inductosense Applications globally.

Cheng Huan received a B.Eng. degree in mechanical engineering and a PhD. degree from University of Bristol, England, in 2015. From 2015 to 2016, he was a Research Associate in the non-destructive testing research group at the University of Bristol. Both his PhD and Research Associate work was focused on the development of passive wireless transducers for structural health monitoring. He is a

co-founder of Inductosense Ltd, an industrial spin-off from Bristol University in 2015 and the Chief Technology Officer. He has managed multiple product development projects such as sensors, handheld data collector and remote data collector.

A Pathway to Thickness Measurement Locations (TMLs) Digitalisation

Synopsis: Permanently installed sensors provide more accurate results compared to conventional inspection due to their consistent positioning and coupling. However, due to their cost, they are normally used for monitoring critical areas for corrosion rate estimation. There are hundreds of thousands of thickness measurement locations (TMLs) on a process site for piping and vessels, making it challenging to monitor all of them. Inductosense has proposed an alternative approach that combines passive sensors and a different data collection method to enable a cost-effective, consistent, and deployable solution with wide sensor coverage possible at low cost.

Dr. Zhong presented their handheld data collector, robotics, and online solutions and demonstrated how they work together to address different applications with accessibility and inspection frequency. The presentation concluded with a large number of case studies aiming to demonstrate the benefits of this approach.

Amongst applications included were:

- Buried Pipeline Monitoring

- Drones

- Erosion Monitoring

- Integrated Corrosion Management

- Manual Wands

- Overhead Pipework Monitoring

- Production Optimisation

- Remote Data Collectors

- Riser and Flowline Monitoring

- Robots and Crawlers

- Ship Tank Usage

- Specialised Vessel Monitoring

- Subsea ROV Data Collectors

The Event provided interesting opportunities for questions.

Please contact the Aberdeen Chair for details of future ICorr Aberdeen Events.

ICorr Aberdeen Joint Online Meeting with TWI

On Tuesday 24th September 2024 the Aberdeen Branch held a joint online meeting with TWI and welcomed Neil Gallon, Principal Engineer of Rosen, with a talk on Welding and Metallurgy Requirements for Hydrogen Service.

Having previously worked for various consulting and manufacturing

companies, including British Steel Tata Steel and GE Wellstream. Neil’s, current work with ROSEN UK concentrates on understanding the effects of gaseous hydrogen on steel properties.

Neil outlined the requirements for

material selection, welding, and metallurgy of carbon steels for gaseous hydrogen service. He also described

the mechanisms and effects of gaseous

hydrogen embrittlement, presented current code requirements in terms of material properties (including welding), and gave an overview of recent research and code developments.

Key Points

Hydrogen embrittlement is the detrimental effect of hydrogen on the mechanical properties of metals and alloys.

-

The fundamental feature that drives much of the integrity concerns and challenges in gaseous hydrogen pipelines is the absorption of atomic hydrogen within the steel microstructure. The interactions of hydrogen can lead to major degradation of mechanical properties such as strength, durability, fracture toughness, and fatigue crack growth rate. These have been studied by various researchers of material types used in repurposed pipelines, such as API Series 5L X42, X52, X65, X80 and X100.

-

The data available to date, is not comprehensive but all show that all performing properties are reduced by increasing levels of Hydrogen.

-

While hydrogen pipelines could be purpose-built, it is very likely that a major proportion of the future transmission network will revolve around the integration of existing natural gas or other hydrocarbon infrastructure. Hydrogen pipeline design codes tend to be more constraining or restrictive than that for hydrocarbons. For example, typical hydrogen standards will limit the use of steels up to API 5L X52 (L360) to tackle hydrogen embrittlement issues, while over 45% of the European NG system is designed with higher steel grades.

-

The Code for Hydrogen pipeline integrity ASME B31.12 lists pipeline materials suitable for hydrogen transportation. Material compositions and properties are more restrictive than “standard” API 5L requirements on items such as the Charpy shear area requirement, the Maximum YS and UTS (including AWT) and a more restrictive chemical composition. The implications are that additional manufacturing and purchasing restrictions will be necessary and existing natural gas pipelines for repurposing may not meet material requirements. From a design perspective and materials performance factor, hydrogen pipelines will operate at lower pressure than that of natural gas unless specific hydrogen test data (KIH) is available.

-

A Material Hardness maximum of 248HV is required for production testing, which is even more severe than sour service requirements.

-

The magnitude of the interaction of hydrogen and steel is determined by the specific nature of the steel microstructures and chemistries, not just the grade. This important facet puts a great emphasis on the understanding of materials ‘DNA’ and on testing. Microstructure performs an important role in achieving higher fracture toughness in the presence of gaseous hydrogen up to 20.7 M Pa and alloy processing design influences final steel microstructure formation.

Mechanism of Hydrogen Embrittlement in Steels

Hydrogen embrittlement is basically the loss of ductility of a metal resulting from the adsorption of Hydrogen.

- Adsorption of H2to the steel surface.

- Dissociation of H2molecule.

- Absorption of H atoms into metal matrix.

-

Diffusion to thermodynamically favoured sites e.g. crack tips, dislocation cores, grain boundaries.

- Actual embrittlement takes place (mechanism unknown).

Hydrogen pipeline integrity depends on material susceptibility, stress, and environment. The possibility of cracking is largely dependent on the environment, and susceptibility to HE is dependent on the amount of hydrogen available. The equilibrium concentration of hydrogen in the metal depends on the partial pressure of hydrogen (Sieverts’ law) and its diffusivity (Fick’s law). At room temperature, H concentration from gaseous hydrogen is very low.

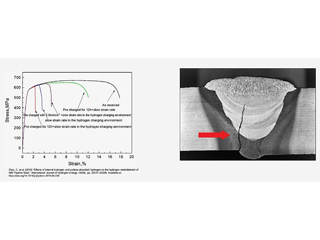

Neil outlined the effect that hydrogen has on pipeline integrity in terms of the principal properties of strength, durability, fracture toughness, and fatigue crack growth rate.

Hydrogen has a relatively small effect on strength at transmission pipeline pressures, while its effect on ductility is more dramatic; this has implications for fracture toughness. Laboratory studies of the effects of internal hydrogen and surface absorbed hydrogen on tensile strength and ductility demonstrate this slight fall in UTS in charged environments, but dramatic loss of ductility from 18 down to ~3% strain levels.

It is also clear that hydrogen reduces toughness from lab studies, but there is large variability in results, possibly due to microstructural differences in pipe grades.

Testing Approaches

There are two main approaches for testing H effects on fracture toughness:

-

Rising load fracture toughness as recommended by ISO 11114-4. This produces a measurable toughness value J, K, CTOD; however, the fracture toughness depends on H kinetics, and the results depend on loading rate.

-

Threshold stress intensity factor KIH – recommended by ASME B31.12 and ISO 11114-4. The results do not depend on H kinetics. However, on the downside, this is a pass-fail outcome, has long testing time with several tests required, and the result is not quantitative.

www.nist.gov/image/materialstestinghighpressurehydrogentestchamberjpg

Studies have also been made of fatigue crack growth rates in hydrogen environments:

-

As yet, there are currently no agreed standard test protocols, but full-scale tests are currently ongoing, and there is currently a lot of research activity in this area.

-

Crack growth da/dt is realised in the laboratory conditions, although there is no evidence that it has happened in pipelines in service, so the implications for pipelines are unknown.

-

Crack propagation does not happen all the time; it appears to be due to the pre-conditioning and stress state around the crack tip, with unpublished evidence that sometimes cracks arrest.

In summary, the requirements for material selection, welding, and metallurgy of carbon steels for gaseous hydrogen service are developed, but there remain areas for further study and development:

- Codes are not mature enough to follow prescriptively.

-

No clear relationship between in-air and in-hydrogen material properties.

-

Likely that extensive programmes of material qualification in gaseous hydrogen will be required.

-

Significant amounts of current code developments and research are necessary.

An extensive Q&A followed this well-attended online event, and the Aberdeen ICorr committee offered its thanks to Neil on following his most informative presentation.

The Aberdeen Branch provides a very full technical programme of both in-person and online events. Abstracts of potential papers for the Aberdeen Technical Programme are always welcome for consideration, and anyone wishing to present should correspond soonest with the 2024/2025 Chair and Technical Programme Co-ordinator: meilingcheah@gmail.com

Further information about the Aberdeen Branch and past presentations may be found on their website page: Aberdeen Branch – Institute of Corrosion. https://www.icorr.org/aberdeen/ under Local Technical Programme and to join the Aberdeen Branch mailing list, please contact: icorrabz@gmail.com

Presenter: Dr. Cheng Huan Zhong.

Neil Gallon, Principal Engineer

of Rosen.

Photo: Explanation of Hydrogen Embrittlement Process.

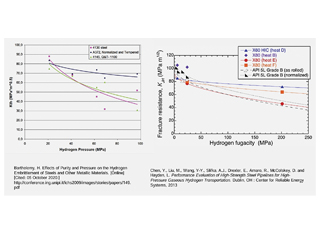

Figure 1: Effects of Internal Hydrogen and Surface-Absorbed Hydrogen on Hydrogen Embrittlement.

Figure 2: Effects of Purity and Pressure on Hydrogen Embrittlement.

Photo: NIST High Pressure H2 Test Chamber.