Institute News

All of ICorr’s 2023 courses were fully booked, and to “clear the waiting list,” we have already launched all 2024 CP training dates on the below website.

https://www.icorr.org/dante-categories/1146/cathodic-protection/

Candidates can now purchase their space on future courses directly. So far, the

new Dante online booking system has been a great success, and we are filling

2024 dates nicely and steadily.

Also, we have started using a secondary training site since September – IMechE in Sheffield—to manage the increased demand particularly for buried courses, and this has worked very well so far. A further centre for CP Marine courses is also being explored.

Institute News

On Wednesday, 13th November 2024, the North-East Branch of the Institute of Corrosion

hosted the Institute of Corrosion 2024 AGM at Neville Hall in Newcastle upon Tyne.

The day commenced with a Technical Offshore Wind Programme, followed by the AGM and concluding with an evening dinner. Almost 70 people from all over the UK attended the Technical Programme and 60 attended the evening dinner, attendees included the ICorr Council, Sustaining Members, Professional members, general members and potential future members. The day was a great success with the variety of engaging content keeping the attendees entertained for almost 9 hours from start to finish.

Matt Fletcher, Chair of the North-East Branch of ICorr, opened proceedings, which was followed by the formal opening of the Technical Program by the Lord Mayor of Newcastle, who welcomed everyone to Newcastle and described how offshore wind and the project to re-paint the Tyne Bridge brought valuable jobs to the region. Lord Mayor also explained that as he did not have his “driver” available, he was unable to wear his full collection of Mayoral Medals as they were too valuable to be worn in public without the extra security of his “driver!”.

The Offshore Wind Technical Programme then opened, consisting of 4 presentations:

Environmental Considerations for Offshore

Wind Foundations Corrosion Protection

Dr. Anthony Setiadi Chief Consultant / Associate Director Wood Thilsted

Anthony described how offshore wind industry growth is accelerating as the world is pushing towards renewable energy sources. These wind turbines need to be installed on foundations located in aggressive environments and are prone to corrosion if not protected and/or designed with corrosion in mind. There are various offshore wind foundation types, such as monopiles, jacket tetrabases, gravity bases, and floating structures. The presentation discussed what level of protection is required, what the options are, and how all of this would impact the structural integrity throughout the design life, as well as how fabrication, transport, and installation limitations would affect the corrosion protection design.

Anthony explained how equally important the environmental considerations need to be taken into account with respect to carbon equivalents in producing and protecting these foundations, as well as the potential byproducts expected. In discussing the creation of habitats for nature, Anthony made an interesting point: if habitats are created on the foundations, what happens to these environments when the foundation is decommissioned in the future?

Assessment of Thermal Spray Aluminium Coating in Synthetic Seawater by Using Complementary Techniques

Dr. (candidate) Adriana Castro Vargas Research Associated – Materials Innovation Centre University of Leicester and NSIRC

Adriana presented the results of her PhD that used complementary techniques, such as in-situ imaging and an analytical rotator, to understand the performance of thermally sprayed aluminium (TSA) coating in simulated marine immersion service. The experimental work involved evaluating TSA in quiescent and flowing synthetic seawater at room temperature. The coating (300 µm thick) was obtained by twin-wire arc spraying of 1050 aluminium alloy on an S355 carbon steel substrate. In quiescent condition, TSA-coated steel samples were evaluated by the optical analysis of sequential images captured in situ: (i) with defects machined before immersion (5% of exposed steel surface); and (ii) with a defect machined after 35 days of immersion (10% of exposed steel surface).

When the defect is machined before the immersion, initial dissolution of iron occurs until the air-formed oxide layer degrades, the electrolyte penetrates the coating, and the aluminium surface is activated. Conversely, when the defect is created after immersion, the aluminium activates rapidly, and the system reaches the range of protective potentials (according to DNV-P-B401), providing immediate protection to the exposed steel. In flowing synthetic seawater, cylindrical coupons were tested in an analytical rotator at 50 rpm and 600 rpm for 10 days. Open Circuit Potential (OCP) and Linear Polarisation Resistance (LPR) measurements were carried out to assess the flow velocity effect and calculate the corrosion rate.

An Introduction to the Offshore Renewable Energy (ORE) Catapult and Its Key Role in Advancing and Derisking Technology in

Offshore Wind.

Mr. Tom Chaplin Marketing Manager Offshore Renewable Energy Catapult

Tom Chaplin provided an introduction to the Offshore Renewable Energy Catapult and described the key role it plays in advancing and derisking technology in offshore wind. ORE Catapult is one of the world’s leading offshore renewables technology centres, with an unrivalled set of test assets that aim to accelerate the creation and growth of UK companies in the offshore renewable energy sector. Established in 2013, ORE exists to accelerate the development of offshore wind, wave and tidal energy technologies in the UK. Through its world-class testing and research programmes and its unique centres of excellence, ORE works with industry, academia and government to improve technology reliability and enhance knowledge, directly impacting the cost of offshore renewable energy. ORE delivers products and services in four main areas: research, engineering, testing and validation, and supply chain growth.

Tom showed the scale of the ORE Catapult testing facilities, showing a video of testing a 107 m blade (which needed to be cut down to 100 m to fit in the test facility) and the 14 GW powertrain, which, as a result of the testing, had its capacity increased. Tom also revealed plans to increase the capacity at ORE Catapult to be able to handle wind turbines well into the future with capability to test blades up to 150 m long (and expansion potential to 180 m) and a significant increase in drive train capacity to 23 MW (with potential expansion to 28 MW).

After the presentation Tom was asked about catastrophic failure during testing; although unable to share images, Tom said it had happened and was quite dramatic. All was not lost, as the fractured blade provided insightful data on blade failure to the owners.

Development of ISO 25249 – Corrosion Protection of Offshore Wind Structures

Mr. Simon Daly Consultant – Energy and Infrastructure Safinah Limited

Simon described how a series of parts of a new international standard, ISO 25249, are currently being worked upon. The standard will address the issues of developing a corrosion protection approach for the protection of offshore wind farms. With the growth in offshore wind will come the need for large-scale construction of assets, which will be placed in a corrosive offshore environment.

While the corrosion of steel structures offshore is well documented through experiences in the oil and gas industry, offshore wind energy has encountered its own challenges when it comes to providing corrosion protection. The ISO 25249 standard will address key issues and develop a framework for a more standardised approach to the selection, execution, and operation of a variety of different corrosion protection methods.

Simon presented on behalf of the program managers for the first 5 parts of this new standard, the development of which will shortly commence within the International Standards Organisation (ISO) framework. During the questions after the presentation, the sharing of experiences gained in the oil and gas industry was discussed. It was generally agreed that to prevent mistakes from 30 years ago being repeated, experiences should be reviewed and shared. It was hoped that with more of the traditional oil and gas companies entering the offshore wind market, this would be more likely to take place.

Following the Technical Program the ICorr AGM took place, details of the AGM can be found in the AGM minutes. At the AGM Stephen Tate passed on the Presidency of ICorr to Yunnan Gao and Yunnan passed on the Vice-Presidency to Anthony Setiadi.

The evening saw a three-course dinner, enjoyed in the library at Neville Hall. As can be seen in the photographs, the library is a beautiful wooden clad room, with many original features, such as elevated bookshelves, bookshelves hidden behind wooden doors, and stained-glass windows. A jazz band played throughout the evening, and the dinner was opened by the new president of ICorr – Dr Yunnan Gao.

Feedback following the event was overwhelmingly positive:

-

“NE Hospitality is famous and you certainly lived up to that.” – Stephen Tate: outgoing ICorr President.

-

“Please accept my thanks for the superb organisation and excellent day yesterday.” – Brian Wyatt of CPGB and Council.

The Chair of the NE Branch of ICorr is grateful to the NE Branch Committee for all their hard work in creating a most successful day; all are volunteers and worked tirelessly to make the event a success. Simon Daly, Patrick Johnson, David Mobbs, Bruno Ravel, Barry Turner, and Josie Watson.

Future Meetings

Due to a date clash with London Branch Dinner, NE Branch will now hold its Xmas (Branch) event at the end of January 2025.

There will be a tour of the Newcastle Castle Keep, the cost of which will be £20 a head.

Please contact nechair@icorr.org for further details.

The Historic Lecture Theatre at Neville Hall.

Photo: The Lord Mayor of Newcastle Upon Tyne Opening the Technical Programme.

Photo: Dr Anthony Setiadi of Wood Thilsted Presenting.

Photo. Dr Adriana Vargas of the Materials Innovation

Centre University of Leicester Presenting.

Photo. Dr Adriana Vargas of the Materials Innovation

Centre University of Leicester Presenting.

Photo. Tom Chaplin of ORE Catapult Presenting.

Photo: New Vice President – Dr Anthony Setiadi, New President – Dr Yunnan Gao, Past President – Stephen Tate.

Institute News

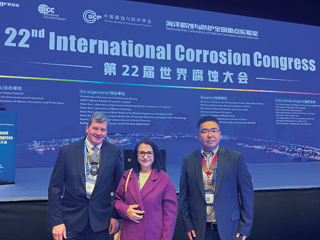

The 22nd International Corrosion Congress, is a prestigious global event dedicated to advancements in corrosion science and engineering and was held on 22nd to 26th October 2024 in Xi’an, China.

Organised by the International Corrosion Council (ICC) and supported by the Chinese Society for Corrosion Protection (CSCP), the congress brought together corrosion experts, scientists, engineers, and industry leaders from around the world. The event aimed to share the latest research, technological innovations, and sustainable practices in corrosion management across many different industries.

The Institute of Corrosion (ICorr), represented by President Stephen Tate and Vice President Dr. Yunnan Gao, attended the congress upon the invitation from the CSCP and the congress organisers, as providing international support to this congress and following ongoing ICorr/CSCP discussions during the previous 12months. The congress featured a diverse program of keynote presentations, technical sessions, workshops, and networking opportunities. Topics ranged from enhancing corrosion controls and corrosion management procedures to new digital tools and artificial intelligence for corrosion monitoring and mitigation. Xi’an, known for its rich history and role as a cultural hub, served as an inspiring venue for this landmark event and attracted a large audience.

During the Congress, ICorr Presidents actively engaged in discussions with the leadership team of the International Corrosion Council (ICC), including ICC past president Prof. Dr. Günter SCHMITT President (2018-2021) from Germany, ICC President (2021-2024) Prof. Emma ANGELINI from Italy, ICC President Newly Elected President in Xi’an (2024-2027) Prof. Vngaranahalli Srinivasan RAJA from India and ICC President Elect (2027-2030), Prof. Dr. Zehbour PANOSSIAN from Brazil.

The ICC Congress provided an excellent platform for ICorr to showcase its initiatives and contributions to corrosion science. ICorr leaders shared insights on professional development programs, such as training and certifications, and emphasised the organisation’s dedication to advancing corrosion engineering standards globally.

ICorr’s participation at this congress greatly enhanced its mission to contribute to global advancements in corrosion control and its aspiration to promote knowledge exchange and innovation within the international community. The interaction between with the ICC leadership emphasised ICorr’s growing influence outside of the UK and reinforced its commitment to strengthening ties with international counterparts.

The ICorr presidents’ successful joint participation in the Xi’an conference highlighted the growing interconnectivity and shared purpose of the global corrosion community. It also set the stage for a future defined by mutual support between CSCP/ICC/ICorr and welcome advancement in knowledge sharing.

Photo: All Attendees of the Opening Ceremony of the 22nd ICC Corrosion Congress in Xi’an. ICorr Presidents: Right 3 and Right 5, 2nd Row, Central Block.

Photo: ICorr Past and Future Presidents and ICC

President Elect (2027-2030), Prof. Dr. Zehbour

PANOSSIAN from Brazil, during the Congress.

Photo: ICorr Past and Future Presidents and ICC Presidents and

Congress VIPs at the Congress Dinner.

Institute News

Each year the Institute of Corrosion bestows a range of internationally renowned awards in recognition of excellence in corrosion science and engineering and to reward outstanding service to the Institute and the wider corrosion community. Many of these awards are open to nomination by both members and non-members of the Institute. Below is a brief description of each award, together with details of how to nominate potential candidates.

U.R. Evans Award

The U.R. Evans Award is the premier scientific award of the Institute of Corrosion and is presented annually for outstanding international achievements in pure or applied corrosion science. The recipient is selected by a Corrosion Science Division panel and presented with an engraved sword at the annual Corrosion Science Symposium (CSS). The symposium is one which seeks to encourage the participation of the junior members of the corrosion community who would appreciate the visit of, and address by, a corrosion scientist of international repute.

The form of the award symbolizes the fight in which we are all engaged. The recipient is also granted Honorary Life

Fellowship of the Institute. Nominations may be submitted at any time via email to the CSD Chair, Julian Wharton (j.a.wharton@soton.ac.uk).

Prof David Shoesmith (University of Western Ontario, Canada) was presented with the U.R. Evans Award 2024 by Stephen Tate (ICorr President) at the 65th Corrosion Science Symposium, which this year joined Electrochem2024 at Manchester Metropolitan University, held between 11th and 13th September. In his plenary talk entitled ‘Corrosion of the Spent Fuel Waste-form and Engineered Barriers in a High-Level Nuclear Waste Repository’, David addressed how various intricate electrochemical investigations into the possible long-term corrosion processes within Canadian/Swedish/Finnish deep geological repositories. This was a very fitting commemoration for the centenary of the first publication of Corrosion of Metals by Ulick Richardson Evans in 1924.

Paul McIntyre Award

The Paul McIntyre Award recognises a distinguished senior corrosion engineer who has demonstrated excellence not only as a leading practitioner in the field but also in fostering European collaboration and advancing international standards. This prestigious award includes an engraved trophy, presented at the annual CED Working Day meeting. The recipient will be invited to deliver a short presentation of their professional contributions and is encouraged to submit an article for publication in Corrosion Management. We’re also excited to announce that the 2024 award winner will be revealed at the upcoming CED Working Day on Corrosion Awareness Day on 24th April 2025. Nominations for the 2025 award are now open and should be submitted to the CED Chair, Danny Burkle, at Danny.Burkle@lbbcbaskerville.co.uk by the end of July 2025.

T.P. Hoar Award

The T.P. Hoar Award is presented to the authors of the best paper published in the scientific journal Corrosion Science during the previous calendar year. The winning paper is selected by a sub-committee of the Corrosion Science Division and the authors receive a certificate and a cash sum of £400.

Galloway Award

The Galloway Award is presented to a student author for the best publication describing original research in corrosion science and engineering as judged by a sub-committee of the Corrosion Science Division. The student should be the primary author of the work and preferably first author. A summary of the winning paper is published in Corrosion Management and the prize consists of a certificate and a cash sum of £300. The Institute does not retain copyright of the material, so this does not prevent separate publication of the work in a scientific journal. Submissions (in the form of a paper published within the past 12 months or a draft publication) may be sent via email at any time to the CSD Chair, Julian Wharton (j.a.wharton@soton.ac.uk). Supervisors may nominate students.

Lionel Shreir Award

The Lionel Shreir Award is given to the best student presenter at the annual Corrosion Science Symposium. Selection of the recipient is carried out by a sub-committee of the Corrosion Science Division. The award consists of a certificate and a cash prize of £125.

The Shreir award in 2024 was presented to Amber Sykes (University of Leeds). Amber gave an excellent presentation linked to her PhD research into the evolution of porous FeCO3 layers, and their influence on the CO2 corrosion rate of carbon steel.

For further details on the Institute awards, including lists of past recipients, please visit https://www.icorr.org/icorr-awards/

Institute News

Report by Sue Wharton, Science in Parliament (SIP) – The Journal of the Parliamentary and Scientific Committee (All-Party Parliamentary Group).

On 15th October 2024, visitors including eleven delegates from ICorr, were welcomed to the discussion meeting by George Freeman MP, new Chair of the P and SC.

The Parliamentary and Scientific Committee is an All-Party

Parliamentary Group funded by Membership – for further details go to

www.scienceinparliament.org.uk

Stephen Tate, President of ICorr, introduced Institute activities; training and informing corrosion engineers at all levels is a key objective. Courses are run, qualifications awarded, specialised meetings held, and financial support given, including for their Young Engineer Programme (YEP), currently running in London.

The APPG then heard four specialist presentations: Gareth Hinds, Senior Fellow and Science Area Leader, Electrochemistry Group at the National Physical Laboratory, gave us his thoughts on ‘Raising Awareness of Corrosion’; David Parker, Environmental Consultant, spoke on ‘The Potential of Value Retention Processes (VRPs)’; Izabela Gajewska, Intertek CAPCIS Consultancy Services, gave us her ideas on ‘Mentoring the Next Generation towards Corrosion Prevention’; and finally Christian Stone of Loughborough University and Concrete Preservation Technologies Ltd, described ‘Advanced Corrosion Management Techniques to Reduce Cost and Risk in Our Built Environment’.

Corrosion costs the UK £80 billion per year. Professor Hinds stressed we must raise awareness of this; we have expert knowledge of corrosion control practices, which could save up to 35% of this total. All countries pay the price of corrosion, and the World Corrosion Organisation (WCO), of which he is currently President, promotes global education and best practices in corrosion control; tackling corrosion also fits well with UN Sustainable Development Goals. Ideally, corrosion control should be incorporated in designs for new projects; unfortunately, undergraduate courses tend not to specialise in the subject, with knowledge generally learnt on the job.

David Parker focused on re-use, explaining the concept of Value Retention Processes (VRPs), Refurbishment and repair, re-use, and remanufacturing were reviewed. Benefits from re-use include reduced emissions, saving raw materials, and more skill orientated jobs. Industry and services are aware of benefits but hampered by regulatory and trade barriers and cost pressures.

Izabela Gajewska, Intertek CAPCIS Consultancy Services, and an ICorr Young Engineer, gave us her views on developing the new generation of corrosion engineers.

Optimised corrosion prevention practices can improve safety, protect the environment, and save money. She listed the varied work of corrosion professionals, reiterated the shortage of new engineers, and suggested suitable courses; experienced specialists retiring impacts the transfer of knowledge. Better communication on education, training, and mentoring would enable and encourage more homegrown students. Christian Stone described advanced corrosion management techniques. Much of our built environment uses reinforced concrete, but mid-20th century public infrastructure can now require intervention; current repair strategies are often lacking and work delayed due to budget constraints. Refurbishment of existing structures is better than rebuilding. Britain is a world leader in corrosion surveying and management; electrochemical surveys pinpoint issues and tailor them to specific locations. Hybrid Galvanic techniques are UK inventions, used worldwide. Recent Reinforced Aerated Autoclave Concrete (RAAC) concerns have been tackled using specific survey methods and anodes, now protecting many public buildings.

A varied Q and A session discussed RAAC safety, reluctance to use new technology, and shortage of specialist engineers. Reactive attitudes persist; only when a collapse occurs do organisations have to rethink. Better communication and design are needed; short-termism is a false economy.

A national register of structures at risk in all areas is considered desirable. Corrosion engineers can play an important role in sustainability and climate change; there should be more awareness of the value of their skills.

The Institute of Corrosion expresses its special thanks for assistance provided to ICorr by Karen Smith, Leigh Jeffes, Roger Brown and Sue Wharton of the Science in Parliament (SIP) Group.

Photo: P and SC Portcullis House, London. Image Courtesy of Parliamentary and Scientific Committee APPG.

Photo: L-R Yunnan Gao (ICorr Vice President), George Freeman MP (Past Minister of State in the Department for Science, Innovation and Technology), Gareth Hinds (Past ICorr President/Speaker), Christian Stone (ICorr Speaker), Stephen Tate (ICorr President/Speaker), Stephen Benn (3rd Viscount Stansgate), Izabela Gajewska (ICorr Speaker), David Parker (ICorr Speaker), David Mobbs (Coatings Specialist) and Douglas Mills (Past ICorr Technical Secretary). Image Courtesy of Parliamentary and Scientific Committee APPG.

Photo: ICorr President Stephen Tate with ICorr MIC Tutor Tony Rizk. Image Courtesy of Parliamentary and Scientific Committee APPG.