The cart is empty!

Developing ISO/DIS 9351 for Galvanic Anodes for CP in Seawater and Saline Sediments

An expert group of corrosion and cathodic protection practitioners from around the world have been busy collaborating in developing a new standard for Galvanic Anodes for CP in Seawater and Saline Sediments.

As Chief Corrosion Engineer with European Energy Birit Buhr says, “After intensive work from the truly global working group under ISO TC 156 WG10 jointly with CEN TC219 WG3, we now have a Draft International Standard (DIS) out for comments.”

In this article, and with the help of Brian Wyatt, Director of Corrosion Control Ltd., certificated to Level 5 in accordance with ISO 15257 by ICorr, we discuss why there was a need for a new standard, the process involved, and how you can now have your say on the final international standard that will emerge from all the work done to date.

The Why of ISO/DIS 9351

BS EN ISO 9351 has been developed from BS EN 12496.

“Many people from outside Europe who were involved in ISO 15589-2 (with the snappy title of ‘Oil and gas industries including lower carbon energy — Cathodic protection of pipeline transportation systems — Part 2: Offshore pipelines’) specifically requested that a new international standard be developed to provide greater availability globally,” says Brian. There was also pressure from within the experts preparing BS EN ISO 24656:2022 ‘Cathodic protection of offshore wind structures’ for this development.

The Process of Developing Standards in the Corrosion Industry

Developing standards is never a simple process. It’s not a straightforward renaming or cut-and-paste exercise. ISO says that the process from first proposal to final publication takes an average of three years, and likens it to a symphony, in which many people work together to develop a standard with ISO in the role of conductor.

The first crucial step in developing standards is to create a group of technical experts nominated by National Standards bodies. It is this team that then takes on the responsibility of creating a draft standard that meets the market need and is technically secure.

From EN 12496 to What We Hope Will become EN ISO 9351

Under the guidance of project manager Birit Buhr, a global team of experts has taken the bull by the horns, and shared their expertise to develop the new standard from the good start provided by EN 12496.

“The outcome of this parallel work by ISO and CEN is a significant improvement from what is currently EN 12496 to this final comment stage, DIS, of what will become EN ISO 9351,” says Brian.

There are some significant changes from EN 12496, which can be summarised as follows:

- Removal of some ambiguities in the definitions and permitted limits on physical properties

- Ensuring convergence of data and properties between this galvanic anode standard and the important ISO DIS 15589-2 (which is also out for vote now)

- Updated and increased range of aluminium anode alloys reflecting developments and needs

- Greater clarity on the known variations in magnesium anode alloy performance

- More extensive requirements and advice in respect of anode performance testing

- More extensive references to support the above data

- A new chapter, supported by Annex E, on environmental impacts providing guidance and recommendations

“The new standard also provides greater clarity in respect of performance variations within the generic composition limits and that optimum performance, in particular for aluminium alloys, may not be delivered within the entire generic alloy range,” explains Brian.

“For clarity, this is likely to mean that if a purchaser states they wish their supplier to deliver, say, alloy A2 and they expect to get the performance in the standard for any composition within the limits given in the standard, they may be disappointed.

“Optimised alloys, within the range but with tighter limits than the range, are required to deliver the optimum performance. Often these alloys will have been subject to patent protection, following extensive testing by their international developer – and the manufacturers may have kept (and may still keep) the production compositions confidential.”

The Standard also contributes to several Sustainable Development Goals, notably:

- Affordable and Clean Energy

- Decent Work and Economic Growth

- Industry, Innovation, and Infrastructure

- Responsible Consumption and Production

- Climate Action

You Are Important in Developing Standards for the Corrosion Industry

The proposed Standard will set basic requirements and give advice for the chemical makeup, electrochemical characteristics, size accuracy, and methods for testing and inspecting cast galvanic anodes made from aluminium, magnesium, and zinc alloys for use in marine applications.

These anodes are used for cathodic protection in sea water and saline sediments, and the proposed Standard covers most types of galvanic anodes used in these environments, specifically cast anodes of trapezoidal, ‘D’, circular cross-section, and bracelet types. It might also apply to other anode shapes like half-spherical or button, which are occasionally used in sea water.

This Standard will be relevant for offshore renewable energy, flood defences, offshore oil and gas industries, submarine pipelines, ports, harbours, ships, and any other situation where galvanic anodes are used for corrosion protection in sea water and saline sediments.

Developing this Standard has been a joint effort between ISO TC 156 WG 10 and CEN TC 219 WG3, led by ISO as per the Vienna Convention between ISO and EN.

With the scope agreed by both parties, and the Draft International Standard written, all those who use the current applicable Standards in their work – and those with expertise in the manufacture and design/use of galvanic anodes in marine applications – are invited to comment on the proposed Standard through their National Standards body (e.g. BSI, AFNOR, SA, DS, AFNOR, DIN, UNI, JSA, SN, ANSI, etc. – we apologise to all key bodies we have not mentioned here).

You can access the full ISO/DIS 9351 either through your national body, or via the ISO portal here.

The official deadline for comments on this standard is 5th January 2024. However, national deadlines will expire before this – so check with your national body when your comments must be entered to them.

Before You Comment on ISO/DIS 9351, Take Note!

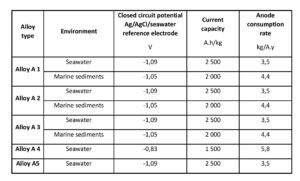

Within the Draft Standard, there is a compilation error in Table C.1.2. This error will be corrected by the Task Group when all comments and votes have been placed and received, for the table to read as follows:

Table C.1.2 — Typical properties of aluminium anodes in normal operation conditions

This is your industry. We urge you to get involved.