The 5th branch event of 2018 took place on Tuesday 29th May 2018 with 46 attendees and with 29 CPD Certificate’s issued on conclusion of the Event.

The evening opened with a short AGM and election of a new committee for 2018-2019 session.

Next year’s Technical Meetings will be held at a new venue – The Robert Gordon University (RGU).

In terms of the committee members, Aberdeen Branch have secured continued commitment from all the existing 2017/2018 members. In addition, we have elected a new committee member, Ms. Zahra Lotfi (MICorr, CEng) who will service the branch from the 2018/2019 session.

Also the branch welcomed back a former committee member, Dr. Muhammad Ejaz who took a sabbatical year in the 2017/2018 session and has returned for the 2018/2019 session.

The established formation of ICorr Aberdeen 2017/2018 committee is now as follows:

Officers:

- Chair: Dr. Yunnan Gao

- Vice Chair: Mr. Stephen Tate

- Corrosion Awareness Chair: Bryn Roberts

- Secretary – External: Mr. Stephen Tate

- Secretary – Internal: Dr. Nigel Owen

- Treasurer/Finance Officer: Mr. Alistair Seton

- Event Co-ordinator: Mr. Amir Attarchi

- University Liaison and CPD Officer: Ms. Zahra Lotfi

Ordinary Committee Members:

- Bryn Roberts

- Hooman Takhtechian

- Muhammad Ejaz

- Philip Enegela.

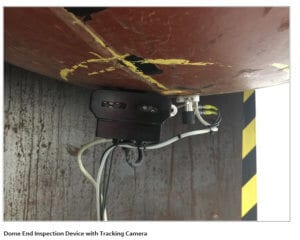

This month’s meeting was a very informative Industrial Visit to Sonomatic (ABZ), with many Presentations and showcasing Specialist Equipment and Facilities for Overcoming / Identifying Corrosion and Integrity Challenges.

It was a wonderful opportunity to witness so many different inspection technologies on display together and it was greatly appreciated by all who came along. It was also very interesting to hear about the Links between Industrial NDT as used extensively in the Oil and Gas Industry and Medical applications of these advanced techniques.

The applicability of the use of NII and possible time saving’s, was explained in the context of the main NII Grading’s of Table 4-1 of G103:

- Type A – No Corrosion likely and Minimum Inspection Requirements / Coverage.

- Type B – Predictable Corrosion Locations / Moderate Rates and Medium Inspection Requirements / Coverage.

- Type C – Unpredictable Corrosion Locations / High Rates and 100% Inspection Requirements / Coverage.

A wide range of Non-Intrusive verification methods were demonstrated, along with discussion of Non-Intrusive Codes such as DNVGL-RP-G103 as further developed by HOIS Joint Industry Project and others.The need for close working co-operation between Inspection Teams and Corrosion Engineers was stressed. Also the importance of post inspection analysis / data review and statistical analysis. When correctly calibrated and deployed, these specialist techniques provide an extremely useful 3 dimensional record of the completed inspection with all high risk areas highlighted / colour coded according to depth of corrosion penetration / pitting.

A full tour of the Sonomatic facilities was kindly provided along with an excellent buffet.

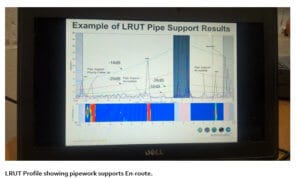

The use of LRUT as an effective screening tool was explained in detail to the audience. Weld locations maybe clearly visualised as high amplitude peaks, as illustrated below. When used properly, LRUT flags up areas showing corrosion activity which require further investigation. This does not necessarily stop at the specific location(s) of the indication(s) detected, but it triggers the operator to perform a higher level of investigation. For instance, if defect indications are detected in sections of straight pipe, adjacent elbows or other fittings may warrant inspection using a complementary NDT technique, e.g. CHIME.

CHIME is a semi-quantitative tool used to inspect pipe material located between two UT probes, which can be up to 1m apart. This is ideal method for pipe supports. LRUT indicates only where there is an indication but CHIME® classifies indications into categories of:

a. No corrosion. b. < 10% wall loss, c. 10% to 40% wall loss d. >40% wall loss

Later in the evening the DRS – Dynamic Response Spectroscopy demonstration showed how modern composite coatings / wraps such as Coal Tar Enamel, Neoprene and Multi-Layer Polypropylene could be effectively inspected, highlighting variations in thickness, the ability to detect internal pitting to +/- 0.5mm and any significant coating defects. DRS uses lower test frequencies to deal with these thicker type coatings.

At the end of the evening, a vote of thanks was given to all the Sonomatic staff, who contributed to this very successful event.

Throughout the evening, wide range of questions followed the very comprehensive presentations and all the presenters’ slides will be available soon on,https://sites.google.com/site/icorrabz/resource-center

Other event photo’s are available on: https://photos.google.com/share/AF1QipO2x5hHaJom3g5ZXwhs6CCqk8sW37gVZjCicIU8HoOVqBTpsiLHuQ9p4t4Y_iK34Q?key=YkduRGtLQzNxcjVRMDlRUnd6NmE1Ujlucmh0dHV3

For information about all forthcoming Aberdeen branch activities, please contact, Dr Yunnan Gao, ICorrABZ@gmail.com. To sign up to the branch mailing list, go to https://sites.google.com/site/icorrabz/home