On November 28, 2023, the Aberdeen Branch meeting welcomed Dr. Douglas Mills and Tianyang Lan with an online talk entitled ‘Assessment of anti-corrosive organic coatings and green corrosion inhibitors by electrochemical techniques, particularly electrochemical noise measurement (ENM).

Douglas Mills gained a PhD in anti-corrosive coatings from Cambridge University, and after spells at the BNF Metals Technology Centre and the Nuclear Power Company, he has worked in academia and has continued to conduct and supervise research in the field of electrochemical methods for application to coatings, studying and advancing the electrochemical noise method. He was for fifteen years the Technical Secretary of the Institute of Corrosion and is also involved in standards development.

Recent Developments in Electrochemical Noise Measurement (ENM) Techniques

ENM is a series of techniques that can be used to assess the corrosion protection effectiveness of organic coatings. The advantages of the techniques are that they are non-intrusive and both ‘quick and easy’ to operate. The interpretation of the gathered

data is not complicated. The main purpose of ENM is to obtain a single parameter, the Noise Resistance (Rn) which relates to protective ability.

This is the standard deviation of the potential series / standard deviation of the current series.

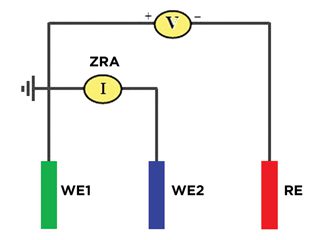

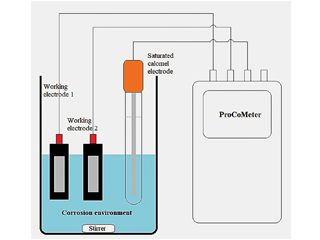

To obtain an R value, three electrodes are required: two nominally identical working electrodes (WE1 and WE2) and one reference (Re). The natural fluctuations of voltage (potential noise) are measured between WE and RE. At the same time, the natural fluctuations of current (current noise) are measured between the two WE electrodes.

The EMN data is typically gathered over about 4 minutes at 0.5-second intervals (512 data points). Repeat runs are made.

The criteria developed in 1948 by Bacon, Smith and Rugg defined the following:

• less than 106 Ωcm2 – poor corrosion protection,

• between 106 Ωcm2 and 108 Ωcm2 – intermediate level of corrosion protection,

• more than 108 Ωcm2 – good corrosion protection.

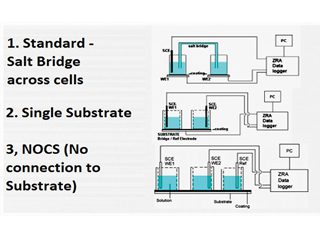

There are a number of different configurations of Electrochemical Noise Measurement techniques as shown in the schematic the Standard Bridge method, the single substrate, and the NOCS termed ‘No Connection to Substrate’.

The experimental work had the following aims:

1. Examination of different arrangements of ENM on a range of coated samples and comparison between them.

2. Checking the reproducibility of results and considering the more practical application of this technique in the field.

3. Investigation of NOCS arrangement of ENM.

Mild steel Q-panels were coated with an appropriate coating in the laboratory by a spreader bar.

The types of coating used in the experiments were mainly polyurethane with some Alkyd and others such as Waterborne Epoxy. To get exposure of the coated plates to the corrosive solution, plastic tubes were attached to the samples and sealed with silicon before filling with 3% Na Cl solution- the area of exposure was ~ 4 cm2. Saturated Calomel electrodes were used to measure the Electrochemical noise. An electrometer (Keithley 610) was used to make DC (Direct Current) measurements to compare Rn values with DC resistance values.

Reproducibility experiments were conducted over a period of 5 days, and they demonstrated that the technique gave stable results after multiple set-ups of the experimental apparatus.

A study was conducted to establish if one area of higher or lower resistance could be detected using the apparatus, i.e., if the Rn value of one area was different than for the other two, are we able to detect the odd one? If so, could we measure its value? A design experiment was set up using all permutations to compare high and low combinations of the coated plate resistances.

Designation of Cell DC Resistance Value (Ω)

A 6,40E+09

B 6,35E+09

C 6,40E+09

Designation of Cell DC Resistance Value (Ω)

X 5,50E+07

Y 1,05E+07

Z 1,30E+07

Six areas were used, three with high resistances A, B, C and 3 with lower resistances X, Y, Z, six combinations altogether.

In conclusion for this work, one single NOCS measurement, made with ACM equipment, when one cell was different from the other two, the research team could, by making multiple measurements, obtain the different value of Rn in the combination when the odd one was connected to WE1.

Using ECN for Green Inhibitor Testing

Tianyang Lan of DC Voltage Gradient Technology and Supply Ltd (DCVG).

Tianyang Lan has obtained both a BSc and MSc in General Engineering at the University of Northampton. During his studies, he conducted some Electrochemical Noise research projects under the supervision of Dr. Mills. He has worked as a researcher at the University of Nottingham, Department of Environmental Engineering, applying electrochemical noise and LPR (Linear Polarisation Resistance) techniques to the testing of green inhibitors. He is now working at the DC Voltage Gradient Technology and Supply Company, which has kindly provided various research equipment for the detection (e.g., ENM) and prevention (using coatings and CP) of pipeline corrosion.

Tianyang demonstrated how the EN Bridge Method can be used to assess a number of chemical inhibitors, both green and standard, for the corrosion of steel in hydrochloric acid.

The solution acts as a conduction ‘Bridge’ in the arrangement. The cell comprises a salt bridge with two working electrodes (5 x 2 cm2 carbon steel) with a Saturated Calomel Electrode as the Reference one. Test specimens were blanked off using a Corrocoat Zip E type coating giving an exposed area of 4.5 x 1.5cm2. Specimen holders were manufactured from an ABS material using 3D printing. The stirring speed was related to the size of the stirrer, (e.g. around 300 RPM for 3 cm stirrer).

The study environments were:

• 1 % Propargyl alcohol (C3 H4 O). in 3 levels of HCl: 0.37 %, 2.6 %,

and 5.5 %.

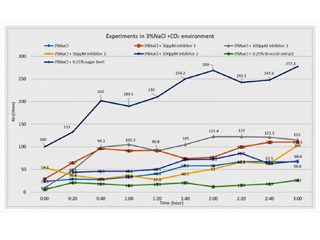

• 0.25 % Green inhibitor (Broccoli or sugar beet) in 3 % NaCl + CO2 /

2.6 % HCl, including two commercial inhibitors.

Propargyl alcohol (PA) is commonly used as an effective inhibitor in HCl solutions in the oil and gas industry. The green inhibitors were experimental test additions.

The results showed that, in Acid, PA provided significant corrosion protection (i.e. a higher Rn), especially in the highest concentration of 5.5% HCl environment. This result follows conventional theory. In 3% NaCl with CO2 bubbling through, the Rn values were found to be increasing over time, apart from when the Broccoli was added, where it actually increased corrosion compared with the control. The 100 ppm dose did better than 50 ppm for both commercial inhibitors, but surprisingly, Sugar beet showed the highest Rn value and also the biggest increase over time, suggesting potential as a green corrosion inhibitor. Comparison was made between the ENM and LPR methods using measurements on the same samples.

• ENM requires two separate iron specimens as working electrodes and one reference electrode.

• LPR measurement requires one working electrode, one reference electrode, and an additional counter electrode. It imposes an external current (±30mV) of the open circuit potential on the specimen.

In summary, the ENM approach gave comparable results to the more established Linear Polarisation Resistance (LPR) method. Further technical events are upcoming by the Aberdeen Branch, refer to Diary Dates at the rear of the magazine.

Abstracts of potential papers for the Aberdeen Technical Programme are always welcome, and anyone wishing to present should correspond with the 2024/2025 Technical Programme Co- ordinator: mei ling cheah meilingcheah@gmail.com Further Information about the Aberdeen Branch, and past presentations, may be found on their website page: Aberdeen Branch – Institute of Corrosion (icorr.org) and to join the Aberdeen Branch mailing list, please contact: icorrabz@gmail.com

CAPTIONS:

Douglas Mills, Senior Lecturer at

University of Northampton.

Left: The Electrode Arrangement is

Shown Here.

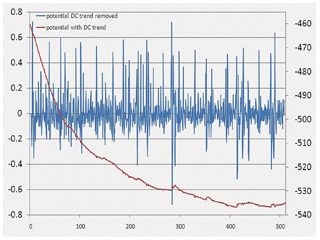

Graph Below:

All Data Obtained

Has to be Normalised by Detrending to Get the DC Potential Signature.

Different Configurations of ENM.

Measurements for a Range of Samples in Bridge and Single Substrate Arrangements of ENM and the Measurements of DC as a Comparative Method for ENM (L-R Salt Bridge, Single Substrate and DC Resistance).

Different ProCoMeter Resistances Deployed for Testing Purposes with Automated Switching of ACM Box.

The ProCoMeter Set-Up.

Various Inhibitors in 3 % NaCl + C02