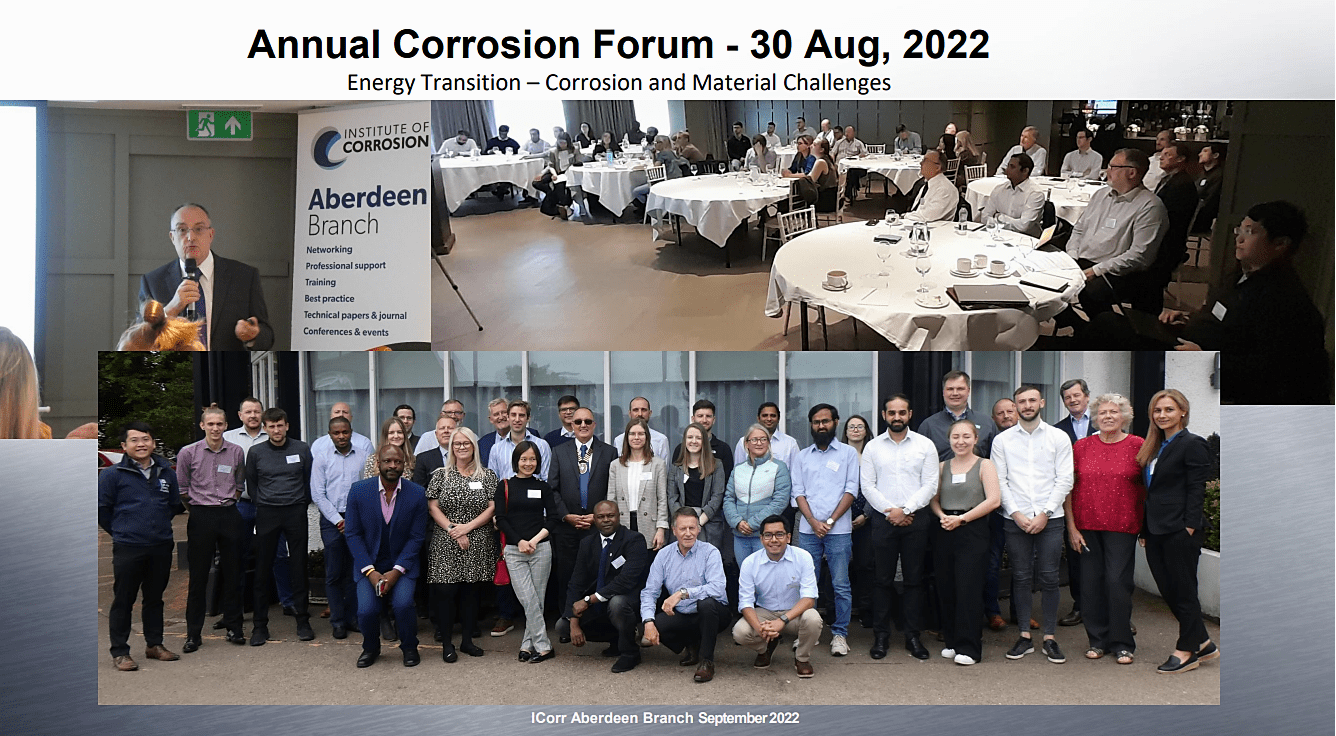

yOn Tuesday 30th August 2022, the Institute of Corrosion Aberdeen Branch held its 2022 Annual Corrosion Forum and was extremely well received. This was a comprehensive whole -day Event of Net-Zero related presentations by a range of industry experts superbly chaired on the day by Dr Olubayo Latinwo and raising nearly £3000 towards ICorr funds for future training programmes.

Presserv Ltd were the Key Sponsor for this event and during the day hosted a demonstration of their products and services, identifying what impact they could have on the energy transition market. Presserv Ltd were also kind enough to arrange the venue (Palm Court Hotel) and also provided catering services throughout the day.

The Event’s key goal was to identify materials, corrosion and asset integrity challenges we face, as we move into the new energy transition era.

ACF outcomes were an extremely useful technical insight for all Conference attendees, companies, duty holders, operators, asset managers and individuals who may wish to transition to greener solutions in the foreseeable future. Rarely are the topics of materials, corrosion and asset integrity the focus of energy transition talk’s and the Institute of Corrosion provided an excellent opportunity to prepare all for the relevant challenges ahead.

ACF Event Chair / ABZ Vice Chair

Dr Olubayo Latinwo

Branch Chair and Event Technical Coordinator

Hooman Takhtechian

Event Speakers and Extracts from their Talks

The Institute of Corrosion’s Approach to the Energy Transition Landscape

P1 Keynote Speaker, Bill Hedges – ICorr President

Dr Bill Hedges spoke from his combined 34 years’ experience in corrosion science, integrity management and engineering and in the oil & gas industry working for Exxon and BP. He was with BP for 24 years and left in 2020 to form his own consultancy business. His final role was as the Chief Engineer for Materials and Integrity Management. He has spent half of his career working in central engineering functions and half in operational locations in many countries worldwide with specific assignments in London, Houston, Trinidad and Alaska. These assignments have given him practical experience of integrity issues in onshore, offshore, deep-water, tropical, desert and arctic environments.

Bill holds a B.Sc. in chemistry and a Ph.D. in electrochemistry (lithium batteries) from the University of Southampton, UK and spent time as a researcher in the Bioengineering department at Oxford University, UK. He is a Chartered Engineer (CEng.), Chartered Chemist (CChem) and a Fellow of both the Institute of Corrosion (FICorr) and the Royal Society of Chemistry (FRSC). He has held director roles with the National Association of Corrosion Engineers (NACE) Foundation and the NACE Europe board. He has published 38 papers and in 2009 was awarded the NACE Fellow honour (FNACE).

The Roles of Corrosion Professionals during Energy TransitionP2

Muhsen Elhaddad – Former NACE Qatar Chair

Muhsen has been working as a Corrosion and Well Integrity Engineer for more than 20 years where he is responsible for designing and implementation of corrosion policies and specifications for upstream, midstream and downstream operations. During his working tenure, Muhsen has contributed a great deal towards advancing the understanding, of transforming companies towards cleaner energies. Muhsen holds a BEng and MSc in material science, engineering and technology, from University of Qatar and is currently pursuing a PhD in electrochemistry, he spoke passionately about the need to have competent and engaging corrosion and materials professionals involved at all levels of the asset cycle from conception of the project to decommissioning.

People are known to be the heart of effective asset integrity management and only people can make effective asset integrity happen with their proactive approach, flexibility and the quick response. They must be knowledgeable, have the right competency, and the authority to act on their knowledge, expertise and experience. They should have the means to collaborate, share and communicate at all levels of the organization and take pride in their profession. This also requires change in mind set and understanding that a job is not for a salary it is a profession that a corrosion professional need to embrace and practice fully.

Material Constraints and safety assessments in conversion of existing natural gas pipelines for hydrogen transport

P3 Frank Cheng – University of Calgary

Dr. Frank Cheng is a Professor and Canada Research Chair in Pipeline Engineering at the University of Calgary. Frank is an internationally recognized researcher in Energy Pipeline Technology, specializing in pipeline corrosion and cracking, integrity management, and new energy transport systems. His talk provided technical background about hydrogen embrittlement (HE), detailing unique features of the problem associated with high-pressure gaseous environments and the additional challenges of the conversion of existing “aged” gas pipelines for hydrogen service. These include corrosion and mechanical defects serving as hydrogen traps, pre-strain induced by pipe-soil interaction to increase the HE susceptibility, competitive adsorption of impurity gases with hydrogen gas on steel surface, and preferential accumulation of hydrogen atoms and the resulting cracking at pipeline welds.

Technical gaps were analysed, and recommendations provided for both research community and industry to develop a technical assessment program for the suitability of existing pipelines for hydrogen transport. Hydrogen, as a green and zero-emission fuel, has received wide attention recently. Hydrogen delivery is integral to the entire value chain of hydrogen economy, where pipelines provide an economic and efficient means to transport hydrogen.

Challenges in assessing corrosion resistance of pipeline steels in dense phase CO2

P4 Shravan Kairy – NPL

Dr Shravan Kairy is a Higher Research Scientist at National Physical Laboratory, UK. His current research is focused on understanding the corrosion of pipeline steels in dense phase CO2 and developing a standard test method. In his presentation, Shravan provided a comprehensive overview of the most common experimental methodologies used to assess corrosion of pipeline steels in dense phase CO2. Key factors that influence corrosion of pipeline steels in dense phase CO2 during service and the challenges of incorporating these factors into experimental methodologies were discussed. The current industry understanding of corrosion of pipeline steels in dense phase CO2 and recommendations on future directions was also provided.

Transportation of carbon dioxide (CO2) is essential for the storage of captured anthropogenic CO2 at dedicated locations, such as depleted oilfields. Pipeline transport of dense phase CO2, i.e., in the liquid or supercritical phase, enables cost effective high throughput transport. Understanding the factors controlling corrosion of pipeline steels in the dense phase CO2 environment is necessary for qualifying pipeline materials for service and establishing reliable and cost-effective impurity threshold specifications.

Challenges in Corrosion Protection for offshore wind Foundations

P5 Anthony Setiedi – Wood Thistled

Dr. Setiadi FICorr has a strong track record of delivering technical and project management roles throughout 20 years in the industry and academia. His work has primarily been in the offshore oil and gas industry prior to the transition to offshore wind. He is currently the Chief Consultant at Wood Thilsted where he is responsible for the corrosion protection design for numerous offshore wind developments in the UK, Europe and USA. He argued that a corrosion protection strategy needs to be developed and agreed well in advance, which then needs to be followed through to completion, including input to Operation and Maintenance Strategy to ensure that structural integrity is not compromised throughout design life.

This presentation primarily focussed on monopile foundations and the design considerations that would need to be taken onboard. Monopiles have both internal and external surface needing protection. Much thought must be given to the level of protection needed and consideration of the impact to structural integrity throughout the design life, and how fabrication, transport and installation limitations would affect the corrosion protection design. Coating requirements and different cathodic protection systems (i.e. Galvanic and ICCP) were discussed for the internal and external challenges regarding positioning of the CP system and installation concerns that need to be taken into account offshore during the installation phases.

Challenges for selecting protective coatings for fixed and floating offshore wind industry

P6 Simon Daly – Safinah Group

Simon Daly B.Eng (Hons) is an AMPP-certified Senior Corrosion technologist and a professional member of ICorr with over 30 years’ experience in the protective coatings field and a consultant with Safinah. His talk highlighted how Corrosion issues within existing fixed wind turbine facilities have necessitated coating requirements more extensive than previously foreseen. Different long term performance requirements, couples with increased productivity to meet offshore renewables targets means that coating selection must be very carefully considered especially with the increasing number of Floating structures.

Offshore wind turbine structures are exposed to environments with high salinity, high levels of UV radiation, the presence of cathodic protection and other factors such as tidal influences. As well as the offshore turbines themselves, larger offshore structures such as transformer stations may have more extensive coating requirements including the need for passive fire protection. As the industry transitions to floating structures designs may also have the challenges associated with marine fouling as well as more extensive coating work scopes.

Challenges in Tokamak-type fusion reactor

P7 Joven Lim – UK Atomic Energy Authority

Joven Lim BEng (Hons), DPhil (Oxon), MIMMM, MInstP is a core member of Reactor Chemistry and Materials Research Working Group of GE Hitachi Nuclear Energy, an experienced nuclear materials scientist with an engineering background. He gave an overview of the Tokamak-type fusion reactor design, the potential list of coolants can be used and why, and the expected corrosion challenges from the extreme environment in the fusion reactor. The speaker also provided some insights on the criteria used for materials selection, corrosion management & mitigation strategy currently being developed for UK STEP fusion programme that aim to deliver a prototype fusion energy plant, targeting 2040 [https://step.ukaea.uk/].

With the increase of national interest to focus on developing and deploying clean energy and ensuring a good energy mix for the future, Fusion power plant is one of the ideal candidates. Fusion reactors do not generate carbon dioxide or other greenhouse gases into the atmosphere. Its major by-product is helium gas. Nuclear fusion reactors do not produce high activity, long-lived nuclear waste. The recent record-breaking 59 megajoules of sustained fusion energy demonstrates potential of fusion to be part of the future energy mix at world-leading Joint European Torus facility, a Tokamak-type fusion reactor design, in Oxford, UK [https://www.euro-fusion.org/news/2022/european-researchers-achieve-fusion-energy-record/].

Corrosion challenges and related opportunities in Arduous next generation low carbon energy systems: Solar and Nuclear Energy Context

P8 Frederick Pessu – University of Leeds

Dr Frederick Pessu is Lecturer in Corrosion, and is based Institute of Functional Surfaces, University of Leeds. He holds a B.Eng degree in chemical engineering, MSc. (Eng) and PhD in Corrosion Engineering and has been working in the areas of corrosion science and engineering since 2009. His research interests have been focused on fundamental understanding and characterisation of material performance in arduous corrosion systems, including renewable and low carbon energy production systems that support energy de-carbonisation, e.g. 1. Molten salts corrosion in Concentrated Solar Power Generation Plants (CSP) and Molten Salt Reactors (MSR). 2. Pitting and overall corrosion in CO2/H2S – containing energy systems; including high scaling geothermal systems.

His presentation highlighted the corrosion challenges in the new frontier of low carbon and renewable energy generation; Solar and nuclear energy sources have shown the greatest promise in our efforts to meet global climate change target. Electricity generation from solar and nuclear irradiation can be achieved using concentrated solar power (CSP) technologies and Gen IV molten salt nuclear reactors (MSR).

Selection of coating material in oil and gas industries and use of advanced coating processes for corrosion protection in present industrial scenario.

P9 Urvesh Vala – Chiyoda Ltd India

Dr Urvesh Vala is presently working as Head, Material Engineering & Technology, L&T Chiyoda LTD. India.

Cross country pipelines and plant piping play vital role for fluid, gas and water transportation which is mainly underground and protective coating with cathodic protection provides more than 25 years of corrosion protection. Protective coatings are the prime method being used globally considering the feasibility, cost and expected service life for onshore and offshore equipment and structures. Coating such as Fusion bonded epoxy, 3-layer polyethylene, polypropylene, modified epoxy, polyurethane, cold applied bituminous, polyethylene tape is most widely used coating for underground piping. Urvesh highlighted in his talk the prime factors for coating system selection – Type of material to be protected / Service temperature / Type of service i.e. open to atmosphere, under insulation, internal/immersion, buried, under fireproofing / Feasibility for maintenance of coating / Expected life.

The use of magnetic probe couple to augment existing equipment and technology.

P10 Jonathan Francis – Trac Energy

Jonathan Francis BSc. (NDT) is a practically minded individual with 3 decades of experience in non-destructive testing within the oil and gas industry with formal qualifications in 5 core NDT methods, Ultrasonics, Radiography, Eddy Current, Magnetic particle and Dye penetrant inspection. Jonathan holds a Bachelor of Science degree in NDT and is in his fourth year of a part-time PHD researching the reliability of manual ultrasonic testing.

Despite the advances and proven reliability of automated ultrasonics (AUT) Manual ultrasonic testing (MUT) is still widely relied upon in industry and has the inherent capability to detect wall loss and give quantifiable data on thickness of components with the data used to ensure plant and equipment can continue to run safely, but the current body of literature shows a host of human factors that can affect MUT performance. The use of a magnetic probe coupler (MPC) is proposed that will aid the task and the inspector in carrying out a reliable MUT inspection. It will do this by ensuring that probe coupling is maintained to the Carbon Steel surface when working in a variety of positions while improving the tactility of scanning a component. It will greatly aid the monitoring of known areas of wall loss by ensuring that the probe is coupled consistently and accurately in the same position.

The Institute of Corrosion Aberdeen Branch gratefully acknowledges the support of all participants and the ICorr HQ Admin Team. Event photos may viewed at https://1drv.ms/u/s!Ajj3m1kM8SgPrj_TTl_bylOPF1LB?e=EfsRMM