Aberdeen Branch, Latest News

The branch opened its 2019-2020 session on 27 August with two linked events on MIC – Microbiologically Induced Corrosion. The well-attended Annual Corrosion Awareness Day (CAD) had a full day teaching programme on MIC risks, mitigations, modelling and bacterial analysis, complimented by an evening visit the following week, to NCIMB Laboratories in Bucksburn and the National Collection of Industrial, Food and Marine Bacteria.

The CAD event featured some excellent talks by Dr Carol Devine (ICR), Drs Laura Tiano and Lone Tang (Danish Technological Institute), Mabel Ntim (Shell), and Drs Ian Laing, Daniel Sandana and Mr Steven Loftus (CAD Co-ordinator), from key Sponsor ROSEN.

Microbiologically influenced corrosion can have a major impact on operators’ CAPEX and OPEX and cause severe environmental damage. A key aim of the CAD workshop was therefore to improve understanding of complex MIC processes, detection of microbiological activity in pipeline systems and management of MIC in the pipeline industry in particular, which has seen many pipelines lost due to internal corrosion in the North Sea sector.

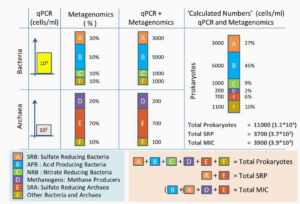

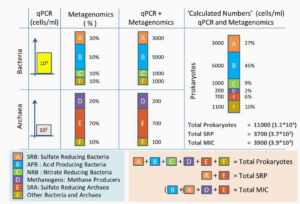

Many analytical techniques were discussed in detail, including qPCR analysis (amplification and quantification of bacterial DNA), traditional culture-based MPN (most probable number), NGS, (next-generation sequencing which has revolutionised biological sciences), Metagenomics (the study of genetic material recovered directly from environmental samples), along with pipeline in-line inspection tools, (deploying a wide range of NDT methods), internal cleaning, chemical treatment and MIC modelling tools for corrosion rate determination.

A lively discussion followed with many valuable viewpoints expressed and with great inputs from the four participating Microbiologists.

The need for an integrated approach to microbial monitoring combining data from multiple techniques, together with taking a fully holistic approach to pipeline integrity management was emphasized to all CAD delegates.

Dr Carol Devine opened the Teaching Programme with a fascinating insight into her career as a Microbiologist entitled “My Life in MIC”.

Dr Laura Tiano (Danish Technological Institute) discusses bacterial sampling options.

Dr Ian Laing, Principal Corrosion Engineer of ROSEN discussed MIC modelling / MIC management, and the vast range of specialist tools available for cleaning and intelligent pigging.

The NCIMB visit on 3rd September built on the previous discussions, with a most informative evening led by Dr Daniel Swan, who was previously Head of Platforms and Pipelines, (now the Genomics Pipelines Group) at the Earlham Institute in Norwich, (formerly The Genome Analysis Centre – TGAC).

NCIMB have 68 years’ experience of preserving, storing, distributing, analysing and exploiting micro-organisms, and are the only privately owned, publicly viewable collection of bacteria in the UK.

A very comprehensive tour of the NCIMB Laboratories followed Daniel’s presentation and recommendations for effective bacterial monitoring strategies, with everyone kitted out in protective clothing to view a wide range of practical demonstrations of bacterial sampling. archiving

and determination.

A peek inside the National Collection of Industrial Food and Marine Bacteria vault: with Samantha Law (Culture Collection Curator).

This most interesting industrial visit to NCIMB, (the first of two in the 2019-2020 programme), generated many questions, so many in fact the event overran by nearly 90 minutes!

At the close of both meetings, the new Aberdeen Chair, Mr Stephen Tate presented all speakers and organisers with Certificates of Appreciation.

Full details of future Aberdeen events can be found on the diary page of the magazine and on the website, or by contacting: ICorrABZ@gmail.com, and all past branch presentations can be found on: https://sites.google.com/site/icorrabz/resource-center

Aberdeen Branch, Uncategorized

The Aberdeen ICorr Branch is very pleased to announce the addition of 3 New Members to its Committee:

- Jonathan Segynola, MSc, Senior Integrity Engineer – Offshore West Africa, (CNR International UK Ltd, Aberdeen).

- Mei Ling Cheah, MSc, Corrosion Engineer, (LR – Lloyd’s Register, Aberdeen).

- Dr Olubayo Latinwo, Corrosion Engineer, (Fairfield Energy Ltd, Aberdeen).

Their combined experience will help strengthen the Aberdeen Technical Programme and its contacts with Local Industries.

We wish them every success in their Terms of Office.

This celebration follows a very successful year for Aberdeen in 2018/2019 Session, with a very well-attended Technical Programme and Summer CAD Event.

Aberdeen Branch, Latest News

The ICorr Induction presentation was performed in September 26th at Aberdeen University by Zahra Lotfi, who is currently Aberdeen ICorr Branch (University Liaison and CPD Officer). This event was excellently organised and the related flyers were circulated well in advance with the support of Aberdeen University, with 35 Students attending on the day.

Dr. M. Amir Siddiq of the School of Engineering, kindly supported ICorr to schedule the Induction Talk just after his Subsea Integrity lecture. This co-operation between ICorr and Aberdeen University resulted in a brilliant turn out of new MSc students, as well as many returning students.

The presentation commenced with introduction to corrosion, corrosion cost, the importance of corrosion control/ mitigate/ monitor, consequents of corrosion with several real life examples of catastrophic failure due to corrosion in oil and gas and transportation, common corrosion degradation mechanisms in oil and gas and the co-operation of different engineering disciplines who can provide the integrity of an asset.

Photo: Presentation by Zahra Lotfi, (University Liaison and CPD Officer) to Aberdeen University Students on 26/09/2019.

The students were introduced to the Institute of Corrosion, its objectives, technical divisions, regional branches, trainings and qualifications provided by ICorr and the many benefits of ICorr membership (e.g. ICorr mentoring program to assist its members to achieve their Chartered Status) and how to apply for ICorr membership.

In addition, the students were familiarised with the work of Aberdeen ICorr branch, the activities calendar, its website and how the institute can assist students greatly in their continuous Professional Development (CPD).

At the Finale, questions on ICorr membership, chartered engineering requirements and local events were discussed in detail. It later continued with a further Q&A session while the students were enjoying eating Pizza provided by Aberdeen ICorr Branch.

Photo: Students enjoy ICorr Catering at Aberdeen University Presentation of 26/09/2019.

Future collaboration events between Aberdeen University School of Engineering and ICorr were also discussed with Dr. M. Amir Siddiq and Dr.Henry Tan.

Great ideas and thoughts were offered by Dr. Yunnan Gao (Immediate Past Chair) on how the students can involve themselves in ICorr activities e.g. by way of a poster presentation or to present their research project in greater detail, at upcoming Aberdeen ICorr Events.

Further details may be found at:

Past Technical Presentation Slides: https://sites.google.com/site/icorrabz/resource-center

Photo Gallery for the Past Events: https://sites.google.com/site/icorrabz/event-gallery

Aberdeen Branch, Latest News

The New Aberdeen Chair Stephen Tate welcomed attendees to its Annual Corrosion Awareness Event

The Aberdeen Branch opened its 2019-2020 session on 27/08/2019, with 2 linked events on MIC – Microbiologically Induced Corrosion.

Its well-attended Annual Corrosion Awareness Day (CAD) had a full day teaching programme on MIC Risks, Mitigations, Modelling and Bacterial Analysis, complimented by an evening visit the following week, to NCIMB Laboratories in Bucksburn and the National Collection of Industrial, Food and Marine Bacteria.

The CAD Event featured some excellent talks by ICR – Dr Carol Devine, the DTI – Danish Technological Institute – Dr Laura Tiano and Dr Lone Tang, from Shell – Mabel Ntim and from Key Sponsor ROSEN – Dr Ian Laing, Dr Daniel Sandana and Steven Loftus, (CAD Co-ordinator).

Dr Carol Devine opened the Teaching Programme with a fascinating insight into her career as a Microbiologist entitled “My Life in MIC”

Microbiologically influenced corrosion can have a major impact on operators’ CAPEX, OPEX and cause severe environmental damage.

A key aim of the CAD Workshop was therefore to improve understanding of complex MIC processes, detection of microbiological activity in Pipeline systems and management of MIC in the Pipeline Industry in particular, which has seen many Pipelines lost due to Internal Corrosion in the North Sea Sector.

Many Analytical techniques were discussed in detail, including qPCR (molecular) analysis, traditional culture based MPN (most probable number), NGS, (next-generation sequencing which has revolutionized biological sciences), Metagenomics, (the study of genetic material recovered directly from environmental samples), along with Pipeline In-Line Inspection Tools, (deploying a wide range of NDT methods), Internal Cleaning, Chemical Treatment and MIC Modelling Tools for corrosion rate determination.

A lively discussion followed with many valuable viewpoints expressed and with great inputs from the 4 participating Microbiologists.

It was emphasized to all CAD delegates, the need for an integrated approach to microbial monitoring, combining data from multiple techniques, together with taking a fully holistic approach to Pipeline Integrity Management.

Dr Ian Laing, Principal Corrosion Engineer of ROSEN discussed MIC Modelling / MIC Management and the vast range of specialist tools available for Cleaning and Intelligent Pigging

Advanced Intelligent Pigging and Cleaning Tools on Display from ROSEN – Key Event Sponsor

The NCIMB Event of 03/09/19, built on the previously weeks discussions, with a most informative Event led by Dr Daniel Swan who was previously Head of Platforms and Pipelines, (now the Genomics Pipelines Group) at the Earlham Institute in Norwich, (formerly The Genome Analysis Centre – TGAC).

NCIMB have 68 year’s experience of preserving, storing, distributing, analysing and exploiting micro-organisms and are the only privately owned, publicly viewable collection of bacteria in the UK.

A very comprehensive tour of the NCIMB Laboratories followed Daniel’s presentation and recommendations for effective Bacterial Monitoring Strategies, with everyone kitted out in protective clothing to view a wide range of practical demonstrations of Bacterial Sampling. Archiving and Determination.

Kyle Sim (Laboratory Assistant) of NCIMB explains the MPN Bacterial Sampling, Serial Dilution and Bacterial Counts to ICorr Attendees

A peek inside the NCIMB Vault – National Collection of Industrial Food and Marine Bacteria: with Samantha Law (Culture Collection Curator)

An example of collaboration between different Bacterial Data Sources and Counts that provides a more effective summary of Bacterial Contamination Status, (by Dr Daniel Swan).

The NCIMB Laboratories Team from L to R, Michelle Robertson (Analytical Services Manager), Dr Carol Phillips (CEO), Sheila Batchelor (Marketing Manager), Vikki Mitchell (Identification Services Manager), Julie Mackinnon (Senior Molecular Scientist), Maggie Bayliss (Inbound Sales Exec), Kyle Sim (Laboratory Assistant) and Dr Daniel Swan (NGS Services Manager)

This most interesting Industrial Visit to NCIMB, (the first of 2 in the 2019-2020 programme), generated very many questions, so many in fact the Event overran by nearly 90 minutes !

At the close of both Meetings, the new Aberdeen Chair, Mr Stephen Tate presented all speakers and organisers with Certificates of Appreciation from the Branch.

Looking ahead, the ICorr Aberdeen Branch will be hosting its annual joint event with TWI – The Welding Institute on 24/09/19 at RGU, which will discuss in detail Environmentally Related Cracking. This talk will cover the topic of SCC on Offshore assets with emphasis on Weldments and HISC issues.

Full details of future ICorr Aberdeen events can be found on the diary page of the magazine and on the website, or by contacting: ICorrABZ@gmail.com

Further photos of both Events may be found on the Aberdeen Branch Gallery:

CAD Event – 27/08/19

https://photos.google.com/share/AF1QipMGp8-SMQdQLin4PLfJVr0W0NrveB7FxS94-zQUfKUUw9fXi4jZmnk-YgS9iLdl8Q?key=djdtYTdQVEZNZ2RyT3drMzdHVlBmbTZYbzhyOTR3

Industrial Visit – 03/09/19

https://photos.google.com/share/AF1QipNtC4h-MzlZ8OwwBB-kOgj8U7THZDcPFkL-k2w7TcIUM_CEK26uGscDqnB9TBvlZA?key=YVRfLV8tNjFTOHFFaTJZbTE3ZjdIREdqSTdXeDN3

Aberdeen Branch, Latest News

The branch have secured continued commitments from all their existing 2018/2019 members and in addition have elected a new committee member, Mr. Jonathan Segynola (Corrosion Technical Authority of CNR)

At the AGM held on 28th May 2019, Stephen Tate and Nigel Owen, were elected Chair and Vice Chair respectively for the 20198/2020 session.

The successful May technical event was jointly organised between ICorr and NACE, and had 49 enthusiastic attendees from across industry and 3 very knowledgeable speakers.

Scott Maidman – Global Deployment Manager of Air Liquide, commenced proceedings with a detailed talk on the merits of Dry Ice Blast Cleaning, as an alternative method of surface preparation. This technique has been designed specifically for use in fabric maintenance in the Oil and Gas industry and similar applications, offering an alternative means of surface preparation and removal of coatings and corrosion. Further development of the equipment has allowed surface profiling through the addition of common abrasives to the dry ice flow. Its additional benefits include a reduced carbon footprint, less waste and post-blast clean up, when compared to other commonly used methods.

Graeme Kennedy – Manager Oil & Gas Downstream UK & Ireland for International Paint, continued with a complimentary talk on Cyclic Corrosion Testing on Surfaces that have been prepared by Dry Ice Blasting. International Paint collaborated with Dry Ice Global and NACE Aberdeen section to investigate the comparative performance of surface tolerant coatings systems when applied to corroded steel surfaces prepared by Dry Ice Blasting, with injected garnet abrasive. International Paint provided pre-rusted carbon steel panels which were blast cleaned and coated with two proprietary coatings systems and then allowed to cure prior to testing. These coated panels were then exposed to ISO12944-9: 2018 (formerly ISO20340 Performance requirements for protective paint systems for offshore and related structures) cyclic corrosion testing, as used in NORSOK M501, Edition 6. The coated panels were all scribed to expose the metal surface and tested for 25 cycles /4200 hours /6 months of alternate UV/condensation, salt spray and freeze to -20°C. The presentation considered the performance of common surface tolerant coatings systems applied over this method of surface preparation, and assessed the corrosion creep from the scribe, and adhesion values, as an indication of performance in the field.

Kennedy of International Paint, in an informative presentation entitled – Cyclic Corrosion Testing on Surfaces Prepared by Dry Ice Blasting.

Out-going chair Dr Yunnan Gao presents Certificates of Appreciation to the event Speakers – Simon Daly, Scott Maidman, and Graeme Kennedy.

Simon Daly – Oil & Gas Segment Manager, Hempel A/S, rounded off a very informative evening with a final presentation entitled ‘Evaluating the Effect of Surface Preparation Standard on Zinc Rich Epoxy Primers’. The presentation focussed on work carried out over an 18 month period with a view to creating consistent reproducible test panels for use in the evaluation of protective coating systems for corrosive environments. Additionally he presented a draft evaluation methodology for combining coating’s application characteristics and long term performance. Simon explained that historically, zinc rich primers have been associated with use as a primary means of corrosion protection on offshore assets at the new construction stage. His presentation investigated the risks and benefits of adopting zinc rich epoxy technology for the far more demanding maintenance phase, by considering/comparing different zinc systems under a variety of sub optimal surface preparation conditions, and the impact upon performance, the effect of the number of coating layers and coating type on system tolerance to salt contamination,

a suitable means of providing consistently prepared test panels to recognized standards, other than commonly applied SA 2.5, and a test methodology for ensuring consistent levels of

salt contamination prior to application and evaluation of

coating performance.

This most interesting series of presentations generated many questions and proposals for future testing programmes.

The branch have secured a continued agreement from the Robert Gordon University (RGU) for use of their main Lecture Theatre (N242), as its venue the 2019/2020 evening events free of charge, and an excellent programme has now been compiled, which will be featured on the Institute website and circulated to all branch sponsors and companion institutes.

Looking ahead, the branch will be hosting its annual full-day Corrosion Awareness (CAD) course on 27th August 2019, (via key sponsor Rosen UK, at the Palm Court hotel), comprising of a number of lectures / presentations focusing on microbiologically influenced corrosion (MIC) in pipeline systems. This year’s CAD programme will include talks by ROSEN specialists and other visiting speakers, on their MIC experiences from global operations covering – Sampling, Analysis, Monitoring of Pipelines for MIC damage, Chemical Mitigation / Cleaning Strategies and finally Inspection, Modelling and Monitoring approaches. Most certainly this event will provide a very comprehensive introduction, to this very significant and often troublesome area of Corrosion Control / Prevention.

Finally, It is with deep sadness that the Aberdeen committee have to report the loss of Alan Foxton, a past ICorr and TWI presenter, and Richard Waud, a valued and regular ICorr attendee, on the 9th and 10th July respectively. Our thoughts are with all their families, friends and colleagues.

As usual, full details of future branch events can be found on the diary page of the magazine and on the website, or by contacting: ICorrABZ@gmail.com

Aberdeen Branch, Latest News

The March meeting was an industrial event at ICR, Bridge of Don, with group presentations and demonstrations of three of ICR’s core business activities.

ICR have specialised tooling and trained engineers, who deal with the insertion and retrieval of corrosion monitoring coupons in live pipeline valve stations (Online Retrievals).

Pre-installed fittings on the pipes allow threaded plugs which carry the mounted coupons to be inserted into the pipe.

This is carried out using either mechanical or hydraulic, telescopic portable tooling which can introduce, through the valve gate, fresh coupons of prepared carbon steel which then sit within the line for the study period. Recovery of the coupons allows for weight loss assessment and corrosion pattern studies, which can be used to evaluate the corrosive nature of the fluid and help to provide remedial measures, such as chemical injection solutions.

ICR also offers on-site weldless, flange to pipe connections which are carried out using a hydraulic colleted + ram system. The flanges to be fitted to the pipe have an annular groove in the inside into which the wall of the pipe can be expanded using tooling inserted inside the pipe end. The hydraulic ram contains a split collet which expands inside the pipe and forces a ring of the pipe wall into the flange grove. This provides a weldless metal to metal gas tight seal which is dressed each end with sealant to prevent water ingress to the junction. This can be performed on pipe to flange connections in any remote situation with 3” to 15” pipes.

A full demonstration of the operation was performed on 10” pipe using the hydraulic compressor and ram, and sectioned flanges were offered to the audience as proof of the integrity and bond.

Finally, a presentation was made on engineering repair solutions for pipe work and structural beam strengthening. These composite repairs use glass and carbon fibre cloth which is soaked in epoxy and then systematically wrapped around surface-prepared pipes, T-junctions elbows or structural beam sections, to cover and reinforce damaged or thinned areas of pipe or steelwork. The wrapping fibre used has a woven nature and anisotropic strength. Once wrapped, a compression bandage is added and within 24 hrs, the epoxy laden fibre will reach its full cured strength. The wrap system is ideal for situations were emergency or temporary repairs are required, but is often suitable for longer term fix until major maintenance programmes are permissible. ICR are also able to wrap pipes under service and low pressure which are leaking. A flanged threaded plate is fitted into the leak and a hose added to divert the leaking fluid while the pipe and edge of the plate are wrapped in the composite. Once the wrap has cured, the threaded plate can be fitted with a blanking plug to reseal the pipe.

At the close of the industrial visit, the Chairman, Dr Yunnan Gao, presented ICR with a certificate of appreciation. Further industrial visits are planned for September 2019 (NCIMB Microbial Laboratories) and March 2020 (Oceaneering NDT).

The April event was the annual joint meeting with the MCF (Marine Corrosion Forum) where the branch were very

pleased to welcome Scaled Solutions Ltd of Edinburgh, to talk on their recent R&D findings into the performance and optimization of corrosion inhibitors, including those for demanding HP (12,000 psi) / HT (300 C) operations.

(The Scottish Government recently recognised Scaled Solutions’ contribution to Research and Development through the provision of a £2.2M grant award in June 2017, to support R&D in several key areas for the Oil and Gas Production industry. This award, together with significant further investment by Scaled Solutions themselves of £3M, should bring significant cost-saving and corrosion prevention benefits to O&G operations).

It is well known that during qualification of a corrosion inhibitor, it is extremely important to carry out laboratory-based assessments that are prudently representative. However in practice, there are many variables that can contribute to the corrosive nature of a system and it is often costly and time consuming to accurately reproduce all the different field conditions. Because of this, investigations are normally carried out using an iterative screening programme, starting with simple tests, followed by product deselection and then further more complex tests. The simplified screening tests then determine the preferred products and dose rates which can pass to the next stage of testing. It is therefore vital that these initial screening tests are carried out in an appropriate a manner as possible.

Hunter Thomson explained how Scaled Solutions’ ongoing research into seemingly small changes to test methodologies and conditions in these preliminary screening tests, can significantly influence the outcome of screening studies. A range of corrosion inhibitors based on common chemistries have been formulated by them to test these effects more precisely, and their extensive results to date have illustrated the controlling effect of aspects such as pre-corrosion, the impact of the brine chemistry, inhibitor composition, as well as the effectiveness of partitioning for different chemicals, on the performance and relative performance of different products.

Hunter highlighted how relatively small changes in the methodology adopted, can lead to considerable differences in the observed performance, ranking, and outcome of the

pre-screening of corrosion inhibitor chemicals, and that thorough understanding and careful design of corrosion inhibitor screening programmes are essential to eliminating possible errors and test artefacts.

This most interesting presentation generated many questions and proposals for future work, covering topics such as effects of intermittent chemical injection, surface area and scaling.

At the close of the meeting, the chair presented Hunter Thomson with a certificate of appreciation.

Looking further ahead, the branch will be hosting its annual full-day Corrosion Awareness course on 27th August 2019, (via key sponsor Rosen), comprising of a number of lectures/presentations focusing on microbiologically influenced corrosion (MIC) in pipeline systems. This year’s programme will include talks by ROSEN specialists and other visiting speakers, on their MIC Experiences from global operations covering, sampling, analysis, monitoring of pipelines for mic damage, chemical mitigation / cleaning strategies, and finally inspection, modelling and monitoring approaches.

Most certainly this event will provide a very comprehensive introduction to this very significant and often troublesome area of Corrosion Control/Prevention, and the provisional programme can be found on the Institute website.

Full details of future ICorr Aberdeen events can be found on the diary page of the magazine and on the website, or by contacting: ICorrABZ@gmail.com, and all past branch presentations can also be found on: https://sites.google.com/site/icorrabz/resource-center

MCF and ICorr Delegates at April Joint Event.

Hunter Thompson of Scaled Solutions Ltd.