The cart is empty!

The Advancing Role of Nano-Coatings in Corrosion Protection

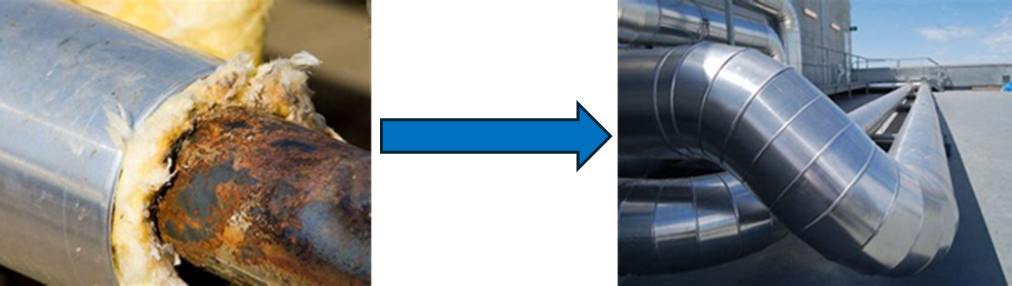

For centuries, corrosion scientists and engineers have been working to create a world in which metal structures can last for longer. Could it be that we are taking a leap toward this nirvana, thanks to the groundbreaking field of nano coatings?

Certainly, recent advances in nanotechnology have ushered in a new era for corrosion resistance, with innovative solutions in nano coatings that offer superior protection, environmental sustainability, and cost efficiency.

One standout innovation is the use of Zinc Oxide (ZnO) nanoparticles, which enhance hydrophobicity and maintain an impressive corrosion resistance level that persists even after extensive exposure. In addition, nanocontainers that encapsulate corrosion inhibitors can now intelligently release their contents in response to specific triggers like pH changes, providing targeted corrosion inhibition precisely when and where needed.

What advances are setting new standards for durability and reliability in corrosion prevention?

How do cutting-edge materials improve current anti-corrosion systems?

Discover the answers to these questions and more in this introduction to the next generation of corrosion protection technology – nano-coatings.

The Advance of Nanocomposite Coatings

In recent years, nanocomposite coatings have captured the attention of pivotal sectors such as automotive, aerospace, oil and gas, and electronics, owing to their revolutionary capabilities. These coatings are meticulously engineered to provide not only aesthetically appealing and cost-effective solutions, but also functionally superior surface treatments. They excel in a wide range of applications including anti-corrosion, antimicrobial protection, anti-fogging, and enhanced adhesion.

Nanocomposite coatings distinguish themselves through several outstanding features, including that they:

- Bolster mechanical strength

- Significantly reduce weight

- Enhance barrier properties while offering superior resistance to heat, wear, and scratches

- Ensure durability and extended lifespan

When compared to conventional anticorrosive coatings, nanocomposite coatings deliver markedly better performance. This enhancement is primarily due to their refined morphology characterised by nanoscale phase-separated domains, which enable more effective protection and functionality across their applications.

Technological innovations have significantly transformed the nano-coatings industry, revolutionising methods of fabrication, manipulation, and application of nano-coatings. These advances are largely propelled by groundbreaking developments in nanotechnology, materials science, and surface engineering.

As a result, new fabrication techniques have emerged, alongside the creation of novel nanomaterials designed with exacting precision in their properties and functionalities. This progress is not only enhancing the performance of coatings, but also broadening their applicability and effectiveness in various industrial applications.

Advances in Preparation of Anticorrosive Nanocomposite Coatings

The field of anticorrosive nanocomposite coatings has seen significant advancements in the engineering of functional nanofilms that are specifically tailored to meet diverse application needs.

Researchers have successfully developed nanofilms that exhibit remarkable mechanical strength, electrical conductivity, thermal stability, and optical transparency. These advances have opened new doors for applications in flexible electronics, transparent conductive coatings, and high-performance sensors.

Additionally, by incorporating functional additives, nanoparticles, and nanoscale structures, these nanofilms have been transformed into multifunctional coatings. Such enhancements provide improved antimicrobial activity, self-healing features, and superior corrosion resistance.

Further, the fabrication techniques for these coatings have also undergone substantial refinement. Methods such as chemical vapor deposition (CVD), physical vapour deposition (PVD), and atomic layer deposition (ALD) have been optimised to allow meticulous control over the deposition processes. These processes ensure nanofilms have consistent thickness, uniform composition, and structured integrity.

In addition, innovations in nanomaterial synthesis through bottom-up approaches, including self-assembly and template-assisted growth, have broadened the spectrum of materials available for nanofilm production, such as metals, semiconductors, polymers, and hybrid composites. Collectively, these developments enhance the functionality and applicability of anticorrosive nanocomposite coatings in various industrial domains.

The most straightforward method for creating anticorrosive nanocomposite coatings involves directly blending inorganic nanoparticle additives with the organic coating matrix.

However, innovation in nanotechnology has shifted towards the design and functionalisation of nanoparticles before they are integrated into the nanocomposite coatings. This pre-integration treatment enhances the nanoparticles’ ability to offer effective and sustained corrosion protection. Such advances include:

· Self-healing nanocomposite coatings

Self-healing nanocomposite coatings are advanced materials designed to autonomously repair damage, such as scratches, cracks, or wear, thereby extending the lifespan and enhancing the durability of the coated surfaces.

These coatings integrate the concepts of nanotechnology and self-healing mechanisms to create systems that can respond to environmental triggers or damage events without external intervention. They not only improve material performance, but also add functionality that can adapt to evolving environmental conditions.Top of Form

· Stimuli-responsive layer-by-layer nanocomposite coatings

Stimuli-responsive layer-by-layer (LbL) nanocomposite coatings are advanced materials engineered to respond to specific environmental stimuli such as temperature, pH, light, or mechanical stress.

These coatings are constructed using the LbL assembly technique, which involves the sequential deposition of alternating layers of positively and negatively charged materials to form a multilayered nanocomposite. This method provides precise control over the thickness and composition of the coatings, enabling the incorporation of functionalities that can react to changes in their surroundings.

These materials not only extend the functionality of traditional coatings, but also pave the way for innovative applications across various industries.

· Organic/inorganic hybrid nanocomposite coatings

Organic/inorganic hybrid nanocomposite coatings are sophisticated materials that combine organic polymers with inorganic nanoparticles to create coatings with enhanced and synergistic properties.

These hybrid coatings exploit the benefits of both the organic and inorganic components, resulting in materials that exhibit improved mechanical strength, chemical resistance, thermal stability, and functional versatility compared to their single-component counterparts. This combination opens up a vast array of possibilities for advanced coatings in numerous industrial applications, driving innovations that enhance the performance and longevity of coated products.

· Electroactive nanocomposite coatings based on electrically conductive polymers

Electroactive nanocomposite coatings based on electrically conductive polymers combine the unique properties of conductive polymers with the enhanced functionalities of nanoparticles to create coatings that can actively respond to electrical stimuli.

These coatings are particularly valuable in applications requiring dynamic control over properties such as conductivity, electrochromism, and electromechanical actuation. Their ability to integrate multiple functionalities into a single coating solution opens up extensive possibilities for advanced technological applications.

· Carbon nanostructures

Carbon nanostructures are a diverse group of materials composed purely of carbon atoms arranged in different molecular configurations, each exhibiting unique properties due to their distinct structures.

These materials are notable for their exceptional mechanical, thermal, electrical, and chemical properties, making them extremely valuable across various scientific and industrial fields. Carbon nanostructures represent a cutting-edge area of material science with the potential to revolutionise industries from electronics to medicine. Their development and integration into functional systems continue to be a hotbed of research and innovation.

Nano-Coatings: The Future of Corrosion Prevention?

The nano-coatings market encompasses a broad range of materials including metals, polymers, ceramics, and composites, each tailored for specific applications across various industries and environmental conditions.

Functionalised nanomaterials have made remarkable strides in enhancing corrosion protection, significantly improving durability, resistance to weathering, UV exposure, mechanical stresses, and thermal variations, while also boosting hydrophobic qualities in anticorrosive formulations.

Innovative materials such as carbon nanotubes, graphene, and nanodiamonds are integrated into polymer matrices to forge nanocomposites renowned for their effective corrosion protection. These composites are particularly efficient due to the intricate diffusion pathways created by the arrangement of nanofillers, which, coupled with interactions between the matrix and the nanofillers, markedly enhance corrosion resistance.

Moreover, the high surface-to-volume ratio and the minute grain size of these nanomaterials intensify their corrosion inhibiting powers, rendering them indispensable in combating corrosion across many diverse industries.

As industries and companies embed sustainable strategies in their operations, the demand for advanced protective coatings is certain to increase. It promises to be one of the major growth sectors within the corrosion industry, with demand for qualified coating inspectors following suit.

Are You Ready to Step Into a Leadership Role in Coating inspection?

Then you’ll find ICorr’s Coating Inspector Courses are exactly what you need. For more information, and to discuss which type of course is best for you, contact ICorr’s admin team by email today.