Institute News

The Midlands Branch is one of our seven ICorr Regional Branches, all strategically located to support our Membership throughout the United Kingdom. They provide a focal point for the local Engineering Fraternity to gather, discuss the pro’s and con’s of the latest technology and also to network socially.

Midlands like all our Branch Committees is made up of volunteers who work together to engage and provide support to the local engineering communities. They also work with other Engineering and Academic Institutions to provide interesting and diverse topics for discussion at a local level including, IMechE, IOM3, Institute of Welding, Institute of Chemical Engineers and also in support of YICorr activities.

Our Midlands Branch had a very successful year during 2023 organising two major all-day events, a Technical Conference at the Birmingham City Chambers in February 2023 and hosting the ICorr AGM at the Birmingham ThinkTank Museum in November 2023.

The Midlands – A Thriving and Developing Area.

In September 2023, the Midlands Branch paid a ‘much in demand visit to UoM (University of Manchester) when Professor of Corrosion Control – Stuart Lyon provided a presentation on the work of the University and the

Corrosion Group, including 65 years of Corrosion History

at Manchester

Midlands Venue: Different venues are used, watch our

magazine Diary Dates or link to each event for details at:

www.icorr.org/events/ The evening events normally start at 18.00 with complimentary drinks with the Technical Presentation following at 18.30. There is a complimentary buffet and a full bar from 19.30 onwards. The meeting generally closes around 21.00.

Should you wish to provide a Technical Presentation to the Branch meeting during its upcoming Technical Programme, then please send an Abstract, Bio and Photo to: Midlands Chair at: midlandschair@icorr.org

For other general enquires about events or supporting the Branch, please feel free to get in touch with the Midlands Branch Committee at: midlandschair@icorr.org

Attendees for the University of Manchester Laboratories Visit.

Institute News

On the 15th February the branch welcomed Paul Lambert, who gave a presentation on “1824 and all that – a celebration of the bicentenaries of Cathodic Protection and Portland Cement”, at the usual venue, the Lancaster Hall hotel, Bayswater, London.

Paul Lambert has over 40 years’ experience in the investigation of structural durability and degradation and in the development of novel remedial techniques for civil and building structures, most recently as Head of Materials & Corrosion at Mott MacDonald. In 2023, he became one of the first three inaugural Mott MacDonald Fellows. He is a past President of ICorr and is currently Chair of the Professional Assessment Committee (PAC). He is also a visiting professor at the Centre for Infrastructure Management at Sheffield Hallam University, where he carries out research into novel materials and repair technologies and is well qualified to talk on this subject.

Historical Background

On January 22, 1824, the Philosophical Transactions of the Royal Society in London accepted a paper for publication entitled ‘On the corrosion of copper sheeting by sea water, and on methods of preventing this effect; and on their application to ships of war and other ships’. The author was Sir Humphry Davy, and it described a study with his colleague Michael Faraday into what we now know as cathodic protection, which celebrates its 200-year anniversary in 2024. It was many years later before the true value of cathodic protection was recognised for the protection of buried and submerged steel structures. It was championed by the formation of the Texas-based Mid-Continent Cathodic Protection Association in 1938, which by 1943 had evolved into the National Association of Corrosion Engineers (NACE, now AMPP) in the USA.

But that is only half the tale. On October 21st, 1824, a bricklayer in Leeds patented a new formulation of hydraulic binder for mortar and concrete which he called Portland cement due to its similarity to the popular structural stone, especially when mixed with beach sand. Portland cement eventually dominated the manufacture of all concrete worldwide.

200 years on, the long-term durability limitations of Portland cement concrete are regularly made good by the application of cathodic protection, making 2024 a very important year for those involved in reinforced concrete and its remediation. So, a happy 200th birthday to Cathodic Protection and Portland Cement. This was a very educational and entertaining presentation, and after questions, Paul was thanked, and presented with an ICorr pen in appreciation.

The branch held its AGM on 14th March, which was followed by the current ICorr President – Stephen Tate, with the bi-annual ‘State of the Nation’ speech.

The current chair of the branch, George Winning, highlighted the positive outcomes from the 22/23 season; hybrid meetings, introduction of webinars in the summer, which will be continued in ‘24, restarting the May event for branch members, which will also continue in ’24, and a very successful Christmas Luncheon. However, in-person and online, attendance were low, and this needs to be addressed.

The London branch treasurer, Jim Glynn, then showed and discussed the accounts for the 22/23 season. The branch receives an allocation from HQ to run all its activities, and after holding 6 evening technical meetings, May event, and the Christmas Luncheon, it returned a surplus of £10,500 to ICorr. Jim then proposed that these accounts be adopted, and this was proposed, and seconded by members attending, and approved.

George Winning as chair noted the 23/24 committee members, and thanked those who were standing down for their services. George stated he was also standing down due to other commitments, and that the new chair for 24/25 would be Paul Brooks, who will take over from the April meeting.

In his subsequent presentation, Stephen paid tribute to his predecessors for their major contributions to the Institute, and thanked the London Committee for its invitation to present this in-depth review of ongoing issues being addressed by the Trustees, and planned improvements to the Institute’s offering to members, both in the UK and overseas, with further opportunities for member engagement, following the successful roll-out of online webinars, that have proved very popular especially with those based outside the UK.

Paul Lambert Presenting on “1824 and All That” – a Celebration of the Bicentenaries of Cathodic Protection and Portland Cement.

George Winning Retiring Chair of the London Branch at the AGM.

Stephen Tate ICorr President Presenting the Bi-annual ‘State of the Nation’

Speech to London Branch.

Institute News

On Tuesday 30th January 2024 the Aberdeen Branch meeting welcomed Dr. Steve Paterson, Arbeadie Consultants Limited for a talk entitled, “Applying materials experience from oil and gas production to carbon capture and storage in North-East Scotland.”

Steve graduated from Imperial College London with a B.Sc. (Eng.) and Ph. D. in Metallurgy. He has over 40 years’ experience in the oil and gas industry, mostly with Shell. His final position at Shell was Principal Technical Expert for Upstream Materials where he was primarily involved in materials, corrosion, welding, inspection and integrity management. He has been involved in several CCS projects during his career and has co-authored papers on materials selection for CCS. Steve is currently an independent materials and corrosion adviser with Arbeadie Consultants based in Banchory near Aberdeen, UK; and is also, an external lecturer in Materials and Corrosion Management at Robert Gordon University in Aberdeen. He was awarded the Institute of Corrosion Paul McIntyre Award in 2019 and EFC Honorary Fellowship in 2023.

Applying Materials Experience from Oil and Gas Production to Carbon Capture and Storage in North-East Scotland

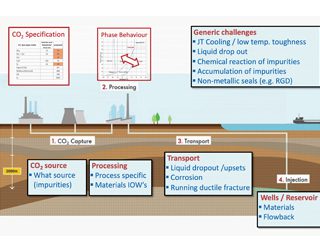

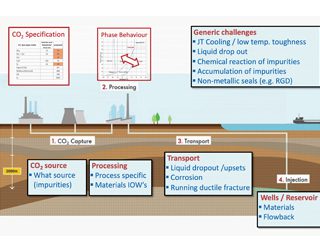

Carbon Capture and Storage (CCS) is a key technology to mitigate emissions from large-scale fossil fuel use. During transport and injection of the CO2 separate liquid phases may form depending on the phase envelope and CO2 composition. These phases comprise of water or reaction products including strong acids and elemental sulphur. The type of liquids formed and shifts in the phase envelope can significantly influence materials integrity including fracture, corrosion, and degradation of polymers. CCS involves the gathering of CO2 from industrial sources, and processing the gas so that it can be transported and injected into sub-surface reservoirs. After capture, the CO2 gas is compressed into ‘Dense Phase’ which is a super-critical fluid state, where its viscosity is similar to that of a gas but its density is actually closer to that of a liquid. It is important that these conditions are achieved for pipeline transport, as this means lower drag and

operating costs.

Experience gained from the oil and gas sector can be used to facilitate materials selection and corrosion control that can address the specific integrity requirements of a CCS project. The presentation also placed in context the historical development of CCS opportunities offshore Aberdeen.

CCS in North-East Scotland has had a number of false starts, beginning with BP in 2005 with the proposed Peterhead CCS project to produce ‘carbon-free’ electricity from hydrogen and inject the CO2 into the declining Miller oil field 240 km offshore for enhanced oil recovery. This was scrapped in 2007 following the decision by the UK government to make funds available only to projects selected via a competition. This led to 3 short-listed bids by Shell, EON and RWE, including capture of CO2 at Scottish Power’s coal-fired Longannet Power Station, transporting it to St Fergus and injecting it in the depleted Goldeneye reservoir 100 km offshore. This project was cancelled in October 2011 due to its high-cost estimate. A new proposal to capture CO2 at SSE’s gas-fired Peterhead station and inject it in the Goldeneye reservoir was initiated in 2012 but cancelled in November 2015. In July 2018 UK government launched the CCUS Innovation programme to deploy CCS in a minimum of 2 industrial clusters by the mid-2020s, and 4 by 2030 at the latest. The aim was to capture and store 20-30 Mt CO2 per year by 2030. The first phase evaluation results in November 2021 confirmed HyNet and East Coast Clusters as Track-1 clusters for mid-2020s, with the Scottish Cluster (Acorn) as a reserve if backup was needed. The UK government confirmed Acorn and Viking CCS systems as Track-2 clusters in December 2023. The Track-2 Acorn project consists of 4 partners: Storegga (formerly Pale Blue Dot), Shell UK, Harbour Energy and North Sea Midstream Partners. In phase 1 the CO2 will be captured from existing St Fergus industrial emitters and transported through the existing 20” Goldeneye pipeline where it will be injected into the Acorn South (Goldeneye) reservoir. In phase 2 the options include CO2 capture and transport from industrial centres around Grangemouth to St Fergus via the National Gas Grid Feeder 10 pipeline, injection in the Acorn Central reservoir via the existing Atlantic pipeline, and a possible international interconnection utilising the Miller Gas System pipeline.

The question remains whether Acorn will actually happen. This will depend on a number of factors, including the high cost of providing the CCS infrastructure, and commitment and funding from the UK government. Only time will tell.

Materials Selection and Corrosion Control

For capture, processing transport and reservoir storage appropriate materials selection and corrosion control is critical. Control can be affected by either avoiding threats that can lead to rapid failure by selecting resistant materials, or by managing threats using a suitable mitigation strategy. Specific threats that can lead to rapid failure include, brittle fracture due to Joule-Thompson cooling, running ductile fracture, hydrogen related cracking mechanisms and stress corrosion cracking. Threats that can be controlled using suitable barriers, including CO2 corrosion and acidic corrosion from impurities. These failure mechanisms were discussed in detail in the presentation by Steve.

For CO2 corrosion there is a wealth of data and many CO2 corrosion prediction models from the oil and gas sector including some based on the traditional De Waard-Milliams relationship. When water is dissolved in dense phase CO2 there is no corrosion, but if water drops out the CO2 dissolves in the water to form carbonic acid and CO2 corrosion becomes a threat. It has been found that at higher pressures the dense phase CO2 corrosion rate is lower than that predicted by the traditional De Waard-Milliams relationship. A revised correlation has been proposed that gives a better fit between field/lab data and model calculations.

CO2 for storage can originate from different sources with a range of impurities such as water, O2, SO2, NO2 and H2S. Impurities may trigger a water phase below normal dewpoint and initiate a shift in tendency of water to condense and create conditions for CO2 corrosion. Impurities can form highly corrosive liquid phases with sulphuric acid, nitric acid and elemental sulphur. Control options for the strong acids are either preventing formation or avoiding drop-out. H2SO4 (and also elemental sulphur) has low solubility in dense phase CO2, so the preferred control option is preventing formation. HNO3 has a relatively high solubility in dense phase CO2 so the preferred option is to avoid drop out by defining strict CO2 specification limits.

The presence of water in CCS systems can lead to breakdown of passivity of low grade CRA such as 13Cr often used for well tubing. High CO2 pressure in CCS can lower pH of condensing water to create conditions where de-passivation can occur. It is well known from oil and gas experience that de-passivation can cause pitting and possible SCC. Parameters that trigger de-passivation include pH, chloride content, temperature and presence of oxygen. For tubulars at the bottom of injection wells in a reservoir with high salinity, the selection of high grade CRAs may be required. CRA materials should be selected for conditions where de-passivation does not occur under any operating scenario. Special attention is required for CRA materials in wells especially if O2 is present in the CO2.

Polymer materials that will be exposed to CO2 should be assessed for rapid gas decompression resistance and the potential impact of impurities. Steve concluded by highlighting that much data and expertise are already available from the oil and gas sector to benefit design and operation of CCS projects, although additional testing may be necessary to confirm suitability for the specific conditions of CCS.

An extensive Q&A session and discussion followed a very detailed and informative presentation.

Predictable Pipeline Performance with Polymer Liners

On Tuesday 27th February 2024 the Aberdeen Branch meeting welcomed Mark Smithson, Subsea 7 Limited with a talk entitled “Predictable Pipeline Performance with Polymer Liners.”

Mark is currently a senior development engineer with the Internal Corrosion Management team for Subsea7 pipeline products. An experienced engineer, he holds a Bachelor of Engineering in Mechanical engineering with industrial management from Liverpool University. Mark has been part of Subsea7’s polymer lined pipe developments and execution for more than 5 years working on a range of projects aimed at increasing the applications applicable to polymer lining. Within this role, he has been responsible for increasing the qualification limits for the new ‘Linerbridge’ connector and currently holds two patents relating to polymer liner developments with a further application pending. Prior to joining the polymer lined pipeline team at Subsea7; Mark worked for Artis, an independent polymer consultancy where he worked on projects ranging from polymer compound development, polymer characterization and product development to testing and process development or optimisation.

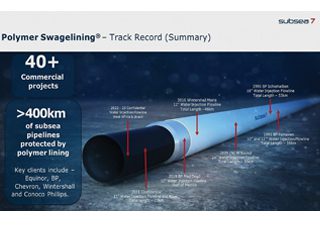

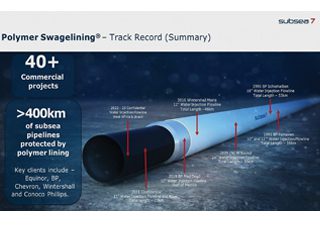

Polymer liners have provided a global, cost-effective solution for internal corrosion mitigation of rigid water injection flowlines for more than 25 years. The first polymer lined subsea pipeline was installed in 1994, since then more than 400 km of high-density polyethylene (HDPE) liners have been installed for subsea water injection service by Subsea7 companies. This track record includes design conditions and qualification programmes demonstrating pressures up to 1293 bar at depths greater than 1,500 m and temperatures up to 80 °C, with the potential to expand all these boundaries.

Reduced pipeline performance due to internal corrosion often leads to a reduction in field output, and an increase in maintenance activities and non-productive time. This results in reduced production and lost revenue. Furthermore, corrosion ultimately leads to pressure downrating or complete failure. The lifetime expectancy of a typical unlined carbon steel (C/S) water injection pipeline is ~ 7 years only and the global cross-industry cost of corrosion is presently estimated at $2.5 trillion annually. Appropriate corrosion mitigation could save industry ~ 35%. Subsea7 have developed innovative swage-lining products which are essentially polymer lined (C/S) subsea pipelines. These products have many advantages, and they can have greater and more predictable service life assurance. The pipeline weight can be reduced, there is increased uptime and the potential to reduce total expenditure costs. The swage-lining products can also offer reduced carbon footprint when compared to competing technologies.

In order to line a steel pipeline with a polymer the swage-lining process is used. This is a proprietary process in which a polymer liner pipe is selected which is of a slightly greater size than the pipe ID. The polymer pipe is pulled through a reduction die at entry and through the length of the pipe under tension, using a pull line threaded through the pipe. The pipe is reduced in diameter by the die and the strain enough to fit through the ID of the outer pipe and is pulled right through. Once in position the tension is released and the liner contracts in length and expands in diameter to form a snug fit inside the pipe.

For connecting the sections of pipe together, there are a few different solutions. There is a Liner bridge and a Weld link product with ridges inside the polymer liner ends into which a compression ring can be forced to seal the polymer against the ID of the pipe.

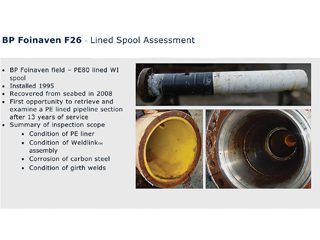

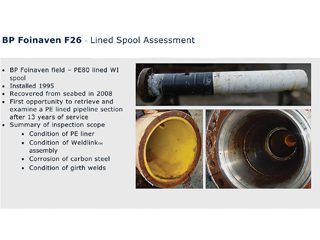

BP Foinhaven – Lined Spool Assessment

Evidence of the efficacy of polymer lining as a corrosion protection technology was demonstrated on the recovery of a spool from a live field at BP Foinhaven F26 after 13 years in service, which demonstrated no deterioration of either polymer material or carbon steel host pipe. Autopsy on the pipe involved sectioning the pipe and machining the interfaces to study the liner condition and the performance of the weld link products.

The PE liner condition was assessed by conducting tensile tests on recovered samples against the specification of 18 MPa and these were found to still be within spec on the 4 samples that were taken from different sites. The liner is also proven to have retained residual stress, indicating a tight fit. Tests were also made for environmental stress cracking and chemical stability. The material had improved stress cracking due to adsorbed service fluid. There was no change in chemical stability. The weld link and compression ring assembly remained fully intact after reeling installation, 13 years’ operating service and recovery. A pull-out test on the PE liner from the weld link joint also demonstrated that the force required to pull the liner out of the assembly exceeds the yield strength of the PE liner even after 13 years. The carbon steel pipe was sectioned, and the liner was removed from the inside of the pipe to examine for corrosion. The pipe had superficial corrosion only and was largely covered in cracked mill scale and rust blooming. The worst corrosion was examined in section and was found to be a maximum depth of 280 micron (0.28 mm) or approximately 1.6 % of wall thickness. Sections were also taken to assess the girth welds and the inner diameter of the carbon steel pipe. Girth welds within the polymer lined section were deemed acceptable, with the liner protecting the weld. Outside the lined section the weld was found compromised due to a fissure in the protective Inconel clad section near the clad flange.

These lining Products now have a significant track record and over 400 km of subsea pipelines have been installed for a number of operators worldwide.

More recently, this well-established flowline product has been supplemented by the qualification of polymer lined pipe for dynamic riser service (steel catenary riser, SCR, and Steel Lazy Wave Riser, SLWR). The qualification programmes included fatigue testing on both full-scale polymer-lined pipe sections and small-scale material coupons. Combined with an investigation of liner behaviour in the vertical orientation. The riser product obtained qualification to technology readiness level (TRL) 5 from the industry-recognised body, DNV.

A deep-water riser has since been fabricated and installed off the back of this programme and is ready to enter service.

Current developments in polymer lining technology have the potential to offer these and other benefits in alternative service environments, such as Water Alternating Gas (WAG), production lines, and new energy transition applications like Carbon Capture, Utilization and Storage (CCUS) and Hydrogen transportation. Mark’s talk was most interesting and very well received. The Aberdeen Branch provides a very full technical programme of both in-person and online events. Abstracts of potential papers for the Aberdeen Technical Programme are always welcome for consideration, and anyone wishing to present should correspond soonest with the 2024/2025 Chair and Technical Programme Co-ordinator: meilingcheah@gmail.com

Further Information about the Aberdeen Branch, and past presentations, may be found on their website page: Aberdeen Branch – Institute of Corrosion (icorr.org) and to join the Aberdeen Branch mailing list,

please contact: icorrabz@gmail.com

Dr. Steve Paterson, Arbeadie Consultants Limited.

Materials and Corrosion Challenges

Mark Smithson, Subsea 7 Limited.

Swagelining® Connectors.

Internal Section of Carbon Steel Pipe After PE Liner Removal Including Girth Weld Region.

Superficial Corrosion of Carbon Steel After Liner Removal.

Polymer Lining – Project History.

Institute News, Uncategorized

World Corrosion Awareness Day’ a University of Manchester / ICorr NW Joint Event

To celebrate World Corrosion Awareness Day, the Institute

of Corrosion Northwest Branch held a joint event with the University of Manchester (UoM) on 24th April 2024.

The event comprised an afternoon of exciting and varied presentations from University of Manchester and

industry speakers:

The Role of Organophosphates in Corrosion Inhibition,

K Brook (University of Manchester)

With a background in the coatings industry, Kathy presented post-graduate research on this innovative area of corrosion prevention.

Cathodic Protection of Wind Turbine Monopiles – Internal and External Issues, David Buxton (Intertek CAPCIS)

David Buxton is a Corrosion Consultant who has spent over 30 years working in cathodic protection and stray current corrosion control. David completed a PhD at the Corrosion Centre (UMIST/University of Manchester) and has been at Intertek CAPCIS for 20+ years undertaking both onshore and offshore cathodic protection related investigations, testing and assessments. He outlined key issues associated with cathodic protection in the emerging area of renewable energy.

Quff: An Innovation in Quantum Computer Programming, Christopher Wright (University of Manchester)

Christopher presented on this new programming language, developed for the fast-moving field of quantum software engineering. Quff is a high-level, dynamically typed

programming language focused on simple yet effective hybrid programme development.

My Corrosion Journey: Dr Jane Lomas

(ICorr / Amtec Consultants Limited)

The talk covered many aspects of the working life of a corrosion engineer and the role that ICorr has played in Jane’s corrosion journey. Whilst obtaining a BSc in Biochemistry, an interest in the problems with corrosion of metal hip joint replacements made an MSc in Corrosion seem a logical next step. This led on to the establishment of an independent corrosion consultancy and jobs ranging from beer

cans to aeroplanes; bulk carriers to battleships; building and factory corrosion issues to corrosion of classic cars, church windows and on the leisure front even Blackpool Tower.

Safety Risks Cannot Be Overstated: The structural integrity

of buildings, bridges, and transportation can be severely compromised by corrosion and have led to many catastrophic failures. https://www.bbc.co.uk/news/uk-england-34335931 and http://news.bbc.co.uk/1/hi/scotland/glasgow_and_west/8495807.stm

The “World Corrosion Organisation (WCO) has previously designated 24th April as “World Corrosion Awareness Day”. This day aims to encourage the adoption of corrosion prevention strategies to reduce the economic and social costs associated with corrosion. The World Corrosion Awareness Day reminds the world that ‘rust never sleeps’ and recognises the impact corrosion prevention and control professionals make. It promotes sustainable management practices for critical industrial assets like energy infrastructure, transportation infrastructure, water/wastewater and waterways, the shipping industry, defence assets, and more.

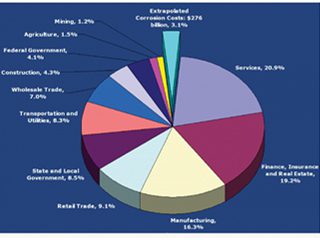

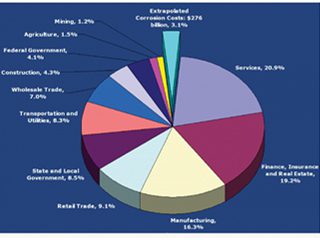

The estimated annual cost of corrosion, amounts to US$2.5 trillion globally and accounts for 3 to 4% of the GDP of developed nations, according to earlier research by AMPP, a global non-profit organisation that represents more than 32,000 members in the materials, corrosion control, and coatings industries. and brought to light on World Corrosion Awareness Day. This figure may be attributed, in part, to the lack of understanding among government and industry decision-makers regarding the seriousness of corrosion and the need for control.

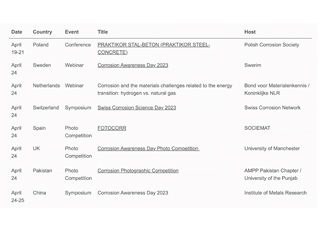

Every year on World Corrosion Awareness Day, seminars, conferences, webinars, competitions, and student events are organised by corrosion associations worldwide to raise public awareness of corrosion and corrosion control among decision-makers in government, business, and academia.

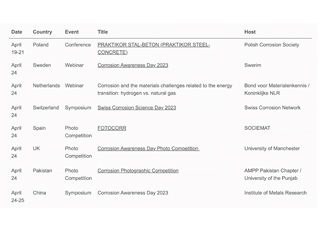

Some of the events conducted on corrosion awareness day 2023 are listed below. An elaborated list of events conducted on corrosion awareness day for previous years is available on

the World Corrosion Organisation (WCO) Website

(https://corrosion.org)

It is estimated that the use of corrosion control techniques will reduce the annual cost of corrosion worldwide by 15 to 35 percent, or $375 to $875 billion. The other intangible advantages to public safety and the environment that come with long-term, consistent asset integrity also add up to these substantial cost savings. Corrosion control specialists are in charge of averting catastrophic failures that can endanger public safety, cause lost output, deteriorate the environment, or result in fatalities.

You may like to read our Corrosion Awareness Day article published on the ICorr website:

www.icorr.org/world-corrosion-awareness-day-family/

Source

www.ampp.org

www.corrosion.org

www.icorr.org

Further Reading

Note: On 1st July 2024, an ICorr Sponsored – Parliamentary and Scientific Committee Event will take place with several Institute speakers including: Professor Gareth Hinds, Dr. Christian Stone and Izabela Gajewska.

Full details will be announced during April 2024. Some recent everyday examples of corrosion impacts to Infrastructure may

be found at:

Coast Road barrier corrosion speed limit to remain – BBC News

‘Severe corrosion’ found during Cleveland Bridge repairs – BBC News https://www.bbc.co.uk/news/uk-england-58494275

Above: An Example of Complex Infrastructure Requiring Special Anti-Corrosion Measures.

Extrapolated Corrosion Costs – Source: www.ampp.org

Above: Events Conducted by Various Corrosion Associations in 2023 on Corrosion Awareness Day.

Institute News

We are thrilled to announce that ICorr & Business Systems Manager at IMechE Argyll Ruane, Dale O’Reilly, has been appointed the Chair of the Institute of Corrosion (ICorr) Yorkshire Branch.

Recognising the need for revival after a period of inactivity, Dale is determined to breathe new life into the branch, leveraging the rich heritage of the City of Steel and the extensive work taking place throughout the Yorkshire region.

His vision is clear: to create a vibrant community of industry professionals coming together to exchange valuable knowledge, share best practice and enhance awareness of corrosion issues, ensuring they are considered in relevant discussions.

Already making strides, Dale has laid the foundation for the branch by utilising contacts from its past to raise awareness and help build a diverse branch membership spanning, inclusive of individuals of all technical capabilities.

Given the expansive geography of Yorkshire, a hybrid approach will be adopted for meetings, ensuring accessibility for everyone to attend in person or remotely.

Get involved!

If you’d like to get involved in the branch and find our when upcoming meetings will take place, please contact: yorkshirechair@icorr.org

Left to Right: Stephen Tate, President of ICorr, Dale O’Reilly, IMechE

Argyll Ruane ICorr and Business Systems Manager, and Dr Yunnan Gao,

Vice President of ICorr.

“Yorkshire is an untapped reservoir of knowledge within the ICorr industry. The goal is to channel this wealth of expertise and involve more individuals in advancing the industry and preventing corrosion in the future.”

Dale O’Reilly, ICorr Yorkshire Branch chair.

Institute News

The new Wales and South-West regional branch held its first ever event on March 21st. The topic was Microbiologically Induced Corrosion (MIC) _ real-world failures and how to prevent them. Presentations were given by the newly elected branch Chair,

Sarah Bagnall of R-TECH Materials and Dr. Gareth Williams of

ECHA Microbiology, based in Cardiff.

This inaugural event was kindly hosted by R-TECH Materials, a material’s testing and consultancy business based in Port Talbot, South Wales. The President of the Institute of Corrosion, Stephen Tate, also attended.

Sarah’s presentation provided a most informative insight into the mechanism of MIC and how the mechanism is identified, common triggers, the affected materials and citing a number of case studies from various industries where failure analysis had been performed by R-TECH both of carbon steel materials, and non-C/S materials affected by MIC. The test equipment deployed, including SEM and XRD analysis, was also outlined and demonstrated in the subsequent laboratory tour.

Gareth’s presentation addressed MIC in the marine and shipping industries and the effects of seawater concentration on sulphate reducing bacteria (SRB).

Gareth described a very interesting project that extended over 18 months, looking at the beneficial contribution freshwater compensation can have when balancing partially emptied vessel fuel storage tanks. A whole range of bacterial types were checked by modern qPCR (genetic) techniques, along with pH and redox potential changes. The advantages and disadvantages of MIC mitigations were also discussed, including: system flushing,

bio-ciding, increased flow rates and protective linings.

A number of the attendees remarked on how they found the presentations most interesting and insightful. The presentations also gained lots of engagement and discussion from the audience, with more than 20 questions and contributions.

The presentations were then followed by a tour of R-TECH Materials’ facility, where numerous attendees commented on how engrossing the tour was and were impressed by the wide range of testing capabilities offered by R-TECH.

AGM

A formal AGM proceeded with the technical meeting, with the following elected for a 12-month term:

- Sarah Bagnall (Chair)

- Adeeba Zachary (Vice Chair)

- Barrie Goode (Student and Liaison and CPD Officer)

- Maryam Bonyadi (External Secretary)

- Rene Brueckner (Finance and Sponsorship Officer)

- Ben Capewell (Events Co-ordinator)

- Chris Weirman (Internal Secretary)

Future Events

The branch is currently arranging events to take place in April

and May, details to follow soon. For further information or if you

are interested in attending future events, please contact:

swchair@icorr.org You can also keep up to date on events by visiting the Branch LinkedIn page; https://www.linkedin.com/groups/12992293/ and the ICorr Wales and South-West webpage at: Wales and South-West Branch – Institute of

Corrosion (icorr.org) and ICorr events calendar at:

https://www.icorr.org/events/

Sarah Bagnall, Chair of ICorr Wales and South-West Branch and Director Consultancy Services of R-TECH Materials Presenting at the Event.

Dr. Gareth Williams, Consultancy Services Manager of ECHA Microbiology Presenting at the Event.

Attendees Touring the R-TECH Materials Facility.