Institute News

On Tuesday 28th March 2023, the

branch meeting welcomed Dr Kevin McDonald – Sonomatic, with a talk entitled ‘Effective pipework analysis and inspection planning using Digital Twins’.

Kevin is a principal integrity engineer within Sonomatic’s integrity team in Aberdeen. He is a mathematician with a PhD in computing science. He has extensive experience in data analytics and inspection planning for pipework, pressure vessels and pipelines, co-authoring the recommended practice for Non-Intrusive Inspection (NII) as applied to pressure vessels. As well as integrity consulting, he is involved in the technical capability development for Sonomatic’s integrity team with a focus on statistical approaches. Recently, he has been involved in developing a statistics-based method of inspection planning and evaluation applied to subsea pipelines for a major operator.

Effective pipework analysis and inspection planning using digital twins

The integrity of pipework is essential for the safe and reliable operation of process plants. Inspections are traditionally performed at large numbers of individual test points, with results recorded in an inspection database. In general, this data is subject to relatively simple analysis, with the results used in integrity management decisions. However, this traditional approach can be heavily influenced by poor processes, outliers, or errors for example: incorrect entry of results, not recording higher thickness readings than those obtained previously, and inconsistencies in inspection location, are some examples of how error can be introduced into this process. This could lead to poor integrity decisions and misinterpretation of wall thickness trends. Analysis of pipework data, which is in general restricted to the difference between two thickness readings relative to the dates the readings were taken, can then be driven by measurement error.

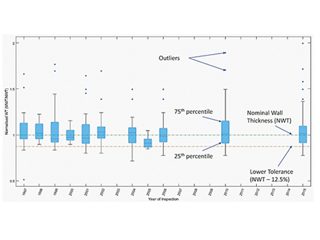

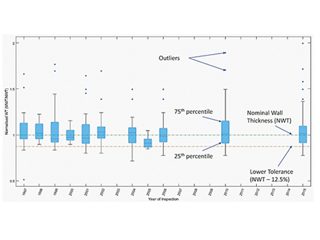

Kevin proposed a novel alternative is to consider historic datasets as a whole and look at long-term statistical behaviour to consider how corrosion could be affecting pipework. This approach looks at whole datasets to determine behaviour before considering any sub-groupings of data points that are showing similar behaviour. The Sonomatic developed SPiDARS software accommodates many data formats. Boxplots can be used to display the whole of an inspection history in one view. In this example a normalised view allows all schedules of pipe to be compared. Boxplots can also be used to provide a quick overview of long-term trends (up or down) and can show stability over several years or highlight changes graphically that cannot be seen from data alone, due to spreads and errors affecting judgement.

The illustrated example shows a downward long-term trend indicative of increased corrosion activity. It provides context and a jump in the final result, indicating replacement of the pipe. Data can also be grouped for pipes by diameter which can show that larger pipes seem to have more corrosion issues than smaller ones, or by pipe configuration feature type such as bends, caps, reducers, or straight sections to search for trends.

Corrosion rates determined from Non Destructive Testing ( NDT) generally trend toward wall loss percentile values as the principal criteria. Looking at group trends mitigates measurement error and gives more accurate short and long-term corrosion rate estimates. Any point showing a concerning trend can be extrapolated to predict when an alarm limit may be reached. Corrosion rate data can be plotted in different ways to try and identify issues such as localised and unusual corrosion rates. Lots of data on wall thickness measurement may just behave in a linear sense such as presented here for selected years and locations – nothing unusual is shown and general corrosion is happening at expected rates.

Sonomatic have developed 3 different inspection planning methodologies. The Type 2 methodology was further discussed with steps detailed below:

• Define corrosion state (is it what we expect to find)

• Define a corrosion coverage from previous results

• Define extent of corroded material

• Define thresholds of concern (based on historic results)

• Consider points flagged as over/under inspected

• Consider expected corrosion mechanisms that have a bearing on applied technique

• Define detection threshold

• Define probability of detection (POD)

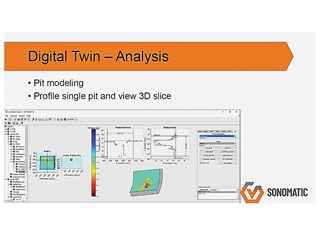

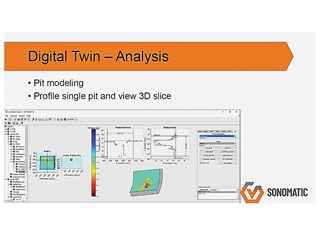

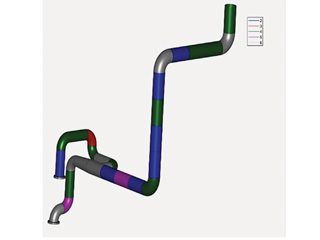

This approach is underpinned by simple and effective access to the data, which is linked to a 3D mini digital twin.

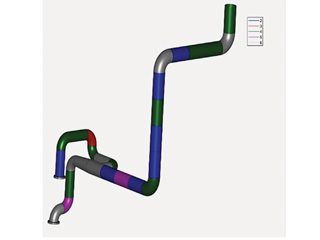

The mini-Twin also hosts a variety of data, as well as individual test points, corrosion maps, and can house inspection histories, photographs, and further data analysis of corrosion rates, fitness for service etc. 3D is used to present data in efficient ways to quickly provide an overview of the health of the pipework circuit, for example inspection frequency, inspection count, corrosion rates, all of which is valuable information for engineers and asset stakeholders.

Considering sub-groupings of features within a pipework circuit has several benefits – a more representative statistical corrosion rate can be calculated per sub-group that will yield better insight into corrosion behaviour, and an illustration of points that could have been over inspected or under inspected, and information on features that may be of concern on other circuits. This methodology can deliver more efficient and targeted inspections, which represents significant cost savings in the form of lower inspection costs, and better planning of when repair or replacement may be necessary.

• Data is screened on upload for spurious points and has automated and electronic reporting. New inspection data can be uploaded to it to refine analysis and it links to mini-Twin.

• Inspection recommendations from SPiDARS are fed into the digital twin for ease of issue. Data extrapolation can be done within the digital twin, and also by SPiDARS – as they talk to each other. This will flag when repair or maintenance is required.

This was a fascinating and very worthwhile presentation from Kevin, that generated much interest from the online audience.

During April, the branch held two events, firstly, a joint hybrid event with the Marine Corrosion Forum, on the 25th April at the Palm Court Hotel. This was followed by an industrial visit to ICR’s premises at the Bridge of Don, to which MCF members were invited, with several demonstrations of ICR’s technology initiatives.

The industrial visit was split into group presentations in rotation for 6 demonstrations, which showed examples of ICR’s core business activities:

• Chemical Injection / Corrosion Monitoring

• OMNI Integrity Management Software.

• QuickFlange™ Weldless Connectors

• Sky-Futures™ Unmanned Aircraft Systems (UAS) Inspection

• Technowrap ™ Engineered Composite Repairs

• INSONO Composite Wrap Integrity Inspection

Chemical injection / corrosion monitoring services are provided throughout the energy sector by ICR who have specialist tooling and trained engineers for retrieving corrosion monitoring coupons, probes, and quills into live pipeline valve stations. The pre-installed fittings on the pipes allow threaded plugs, which carry the mounted coupons, to be inserted into the pipe. This is carried out using either mechanical or hydraulic, telescopic portable tooling, which, through the valve gate, can introduce fresh coupons of pipe grade material which sit within the line for the study period and suffer metal loss through corrosion in the fluid stream. Recovery of the coupons allows weight loss assessment and corrosion pattern study, which can be used to evaluate the

corrosive nature of the fluid and help provide remedial measures such as chemical injection solutions, for which ICR supplies a range of pumping equipment.

OMNI is a cloud-based integrity management software that enables full-lifecycle digitalisation to be tailored and implemented in line with organisational requirements and can connect directly to the latest advancements in technology, such as digital twins (as described above), robotics, and corrosion sensors. OMNI is configured as an ‘all in one’ platform, able to capture all integrity and inspection data formats, compare and provide real-time defect detection and enable the close-out through anomaly and repair –- offering improvements to operational safety and reliability. Organisations can communicate and manage operational workflows more effectively using OMNI’s innovative features such as process automation, tracking and online collaboration, allowing for better safety and operational risk management and supporting legislative compliance.

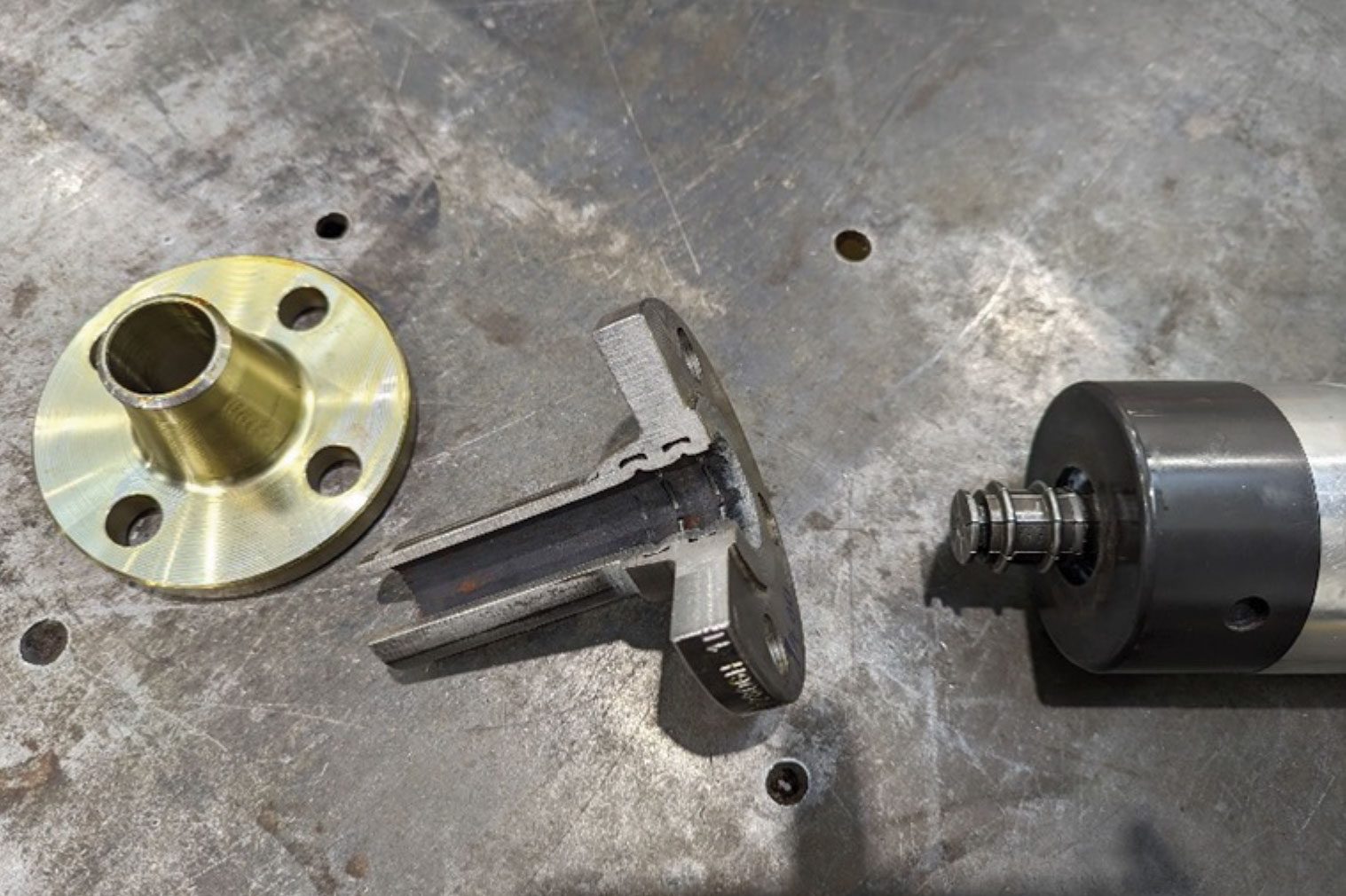

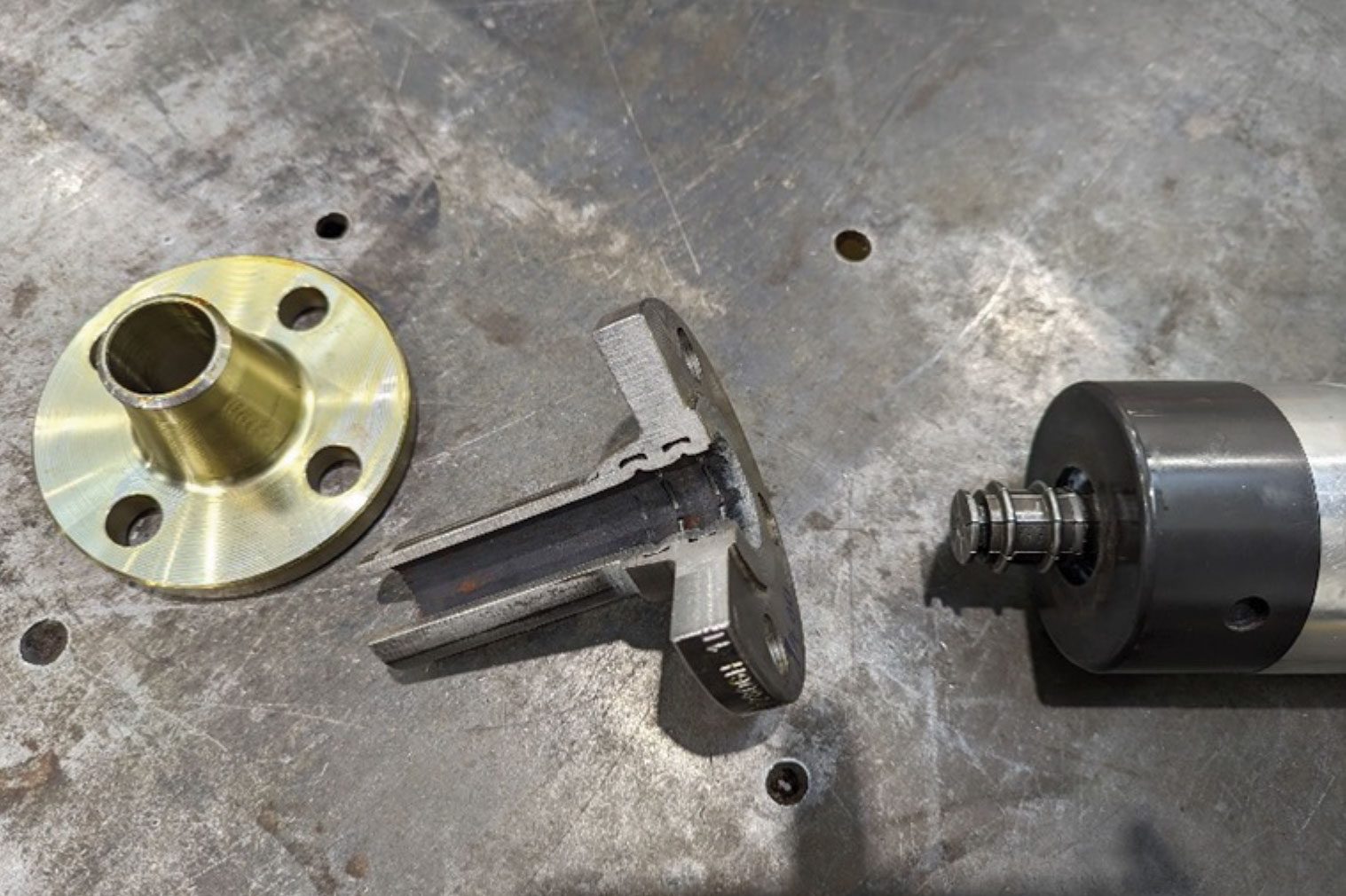

ICR also offers on-site weldless, flange to pipe connections (Quickflange TM), which are effected using a hydraulic, colleted ram system. The flanges to be fitted to the pipe have an annular groove in the inside of the flange into which the wall of the pipe can be expanded using tooling inserted inside the pipe end. The hydraulic ram contains a split collet which expands inside the pipe and forces a ring of the pipe wall into the flange grove. This provides a weldless metal to metal gas tight seal which is dressed each end with Belzona sealant to prevent water ingress to the junction. This can be performed on pipe to flange connections in any remote situation for 3” up to 15” connections. A full demonstration of the operation was performed on 10” pipe using a hydraulic compressor and ram, and sectioned flanges were offered to the audience as proof of the integrity and bond.

ICR also offers on-site weldless, flange to pipe connections (Quickflange TM) which is affected using a hydraulic, colleted ram system. The flanges to be fitted to the pipe have an annular groove in the inside of the flange

Sky-Futures™ UAS drone inspection devices are a relatively new addition to ICR’s services, and these are widely used across the energy sector including more recently for integrity assessment in the Beatrice wind farm in Scotland’s Moray Firth, as was further discussed at the event.

The turbine’s support structure and blades had exhibited various forms of damage and irregularities, including cracks and compromised safety components, previously identified by rope access personnel. Furthermore, as the turbines were due to reach the end of their service life in the next five years, it was crucial to visually confirm the structures’ overall condition and ensure their continued functionality. This method has reduced the exposure of personnel to working at height and enabled a swift and thorough inspection deploying ultra-high-resolution imagery, to evaluate identified anomalies. The following component areas of the two turbines were successfully inspected to identify any potential dropped objects, or other conditions which could impact the safe decommissioning of the turbines later including:

• Access platforms

• Jackets

• Nacelles

• Support towers

• Turbine blades

The detailed reports and accompanying imagery later provided the client with a comprehensive understanding of the condition of the turbines and their support structures, serving as a crucial component of their future decommissioning strategy.

Technowrap ™ Engineered Composite repair solutions widely used in the North Sea were presented for pipework and structural beam strengthening. These repairs use glass and carbon fibre cloth, which is soaked in epoxy and then systematically wrapped around surface prepared pipes, T-junctions, elbows or structural beam sections, to cover and reinforce damaged or thinned areas of pipe or steelwork. The wrapping fibre used has a woven nature and anisotropic strength. Once wrapped, a compression bandage is added, and within 24 hours, the epoxy laden fibre will reach full cured strength.

The wrap system is ideal for situations where emergency or temporary repair is required but is often suitable (when fully engineered at the outset) for a longer-term fix until major maintenance programmes are permissible. ICR is also able to wrap/resolve low pressure pipes that are leaking under service. A flanged threaded plate is fitted into the leak, and a hose is added to divert the leaking fluid while the pipe and edge of the plate are wrapped in the composite. Once the wrap has cured, the threaded plate can be fitted with a blanking plug to reseal the pipe!

INSONO is an innovative NDT technique for the inspection of engineered composite repairs that is now widely used across the energy sector. This system can validate the condition and integrity of composite repairs, providing operators with assurance of their application and long-term performance. INSONO detected defects fall within three main areas: the composite laminate, the bond line, and the substrate. Based on the principles of the acoustic inspection method with pitch and catch, resonance and mechanical impedance analysis can detect and size the defects. A scanner provides 3D models and a visual representation of the composite repair, allowing for precise dimensions to be used in the assessment. ICR’s manually operated, angled probes are designed to access all geometries and system configurations, detect defects in the composite material, the bond line, and the steel substrate and provides a user-friendly automated inspection report.

The ICR event was a fantastic opportunity to witness one of Aberdeen’s long-standing ICorr sponsors in action and proved to be a most enjoyable evening.

ICorr Aberdeen welcomes suggestions for further industrial visits.

Abstracts of potential papers for the branch technical programme are always welcome, and anyone wishing to join the committee should correspond with the 2023/2024 Technical Programme Co-ordinator: Adesiji Anjorin, anjorin@gmail.com

Further information about the branch, and past presentations, may be found on their website page: Aberdeen Branch – Institute of Corrosion (icorr.org), and to join the Aberdeen Branch mailing list, please contact: icorrabz@gmail.com

Dr Kevin McDonald, Sonomatic.

Boxplots, Sonomatic

Digital Twin – Analysis, Sonomatic.

3D Data Profiling, Sonomatic.

ICR Chemical Injection and Corrosion Monitoring.

ck Flange™ Weldless Connectors.

ICR-Sky Futures, Drone Inspection.

Technowrap ™ Engineered Composite Wrap, ICR.

Technowrap ™ Engineered Composite Wrap, ICR.

Institute News

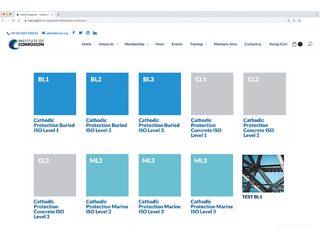

Dante – The New CP Bookings System

The Institute is very pleased to announce the introduction of its new CP training bookings System – Dante, which will be managed by CPSM under the skilful eye of Eva Whittaker

Institute News

The branch held its last technical meeting of the 22/23 season on 13th April, when Reza Beheshty, Subject Matter Expert in Materials Corrosion, Welding, & Coating, Fluor, presented on “Flow Accelerated Corrosion.

Flow Accelerated Corrosion (FAC) is primarily a corrosion process aided by the chemical dissolution of an internally formed iron oxide protective layer in carbon steel piping and process equipment, followed by its transportation into the bulk fluid in the direction of flow (generally unsaturated water and wet steam) by means of mass transfer. This results in wall thinning (up to 10 mm/y) until complete rupture, if not detected and/or remedied. It is a significant damage mechanism common to power plant and industrial steam cycle systems and has been a concern there for many years.

The rate of metal loss by FAC depends on a complex interplay of several parameters. The challenge is to find a functional relationship between the hydrodynamic severity of the flow (i.e., mass transfer rate) and the environmental parameters influencing the FAC rate, mainly fluid temperature, pH, and oxygen concentration. Also, the amounts of chromium, molybdenum, and copper in the steel are very important material factors in prevention of FAC.

Even though the main influencing parameters are well recognised, major failures are still occurring at the same locations that were found in the 1980s and 1990s. Power plant owners’ major concern is that the FAC problem seems to be fading away in the minds of plant operating management at many facilities as a result of retirements in the power industry, while new personnel simply do not understand the importance of FAC control. Besides understanding the positive combination effects of the FAC influencing parameters for managing FAC proactively, without the need for utilising expensive tools, are still not completely understood.

One of the most well-known, and effective predictive models, for calculating FAC rate, considering the various parameters influencing FAC, was proposed by Chexal & Horrowitz et al [1], as shown below.

FAC rate (thinning loss) = f(T) x f(pH) x f(O2) x f (a) x f(MT) x f(G) x f(AC)

Where the various factors represent, temperature effect (T), pH effect (pH), dissolved oxygen concentration effect (O2), void fraction i.e., steam quality effect, for two phase FAC only (a), mass transfer (i.e., flow rate and pipe diameter) effect (MT), geometry effect (G), and alloy content impact, i.e., effect of chromium, copper, and molybdenum content (AC).

The primary objective of this presentation was to refocus on different FAC mechanisms, and to understand the effects of each of these parameters (as indicated in above model), and postulate how the combination of these influencing parameters could positively result in controlling the FAC damage with an increased level of confidence with carbon steels, in the absence of specific and expensive FAC predictive tools.

[1] Technology development by the U.S. industry to resolve erosion-corrosion, B. Chexal, N. Dietrich, J. Horowitz, W. Layman, G. Randall, V. Shevde, Electric Power Research Institute, published by international working group on reliability of reactor pressure components, IWG/-RRPC-88-1, Corrosion and Erosion Aspects

in Pressure Boundary Components of Light Water Reactors,

September 1988.

The branch resumed its end of season social event, after a number of years, with a canal boat trip on the Regents Canal through London, on the 11th May.

The cruise started at Paddington where 33 local members and supporters boarded, and enjoyed a light snack, while we set off. Once underway, and as we passed Little Venice on the way to Camden, taking in the many varied views along the route, further refreshments, including sandwiches and cakes, as well as beverages from the bar, were made available to the guests. As the boat passed through the grounds of London Zoo, the guests looked out for the African wild hunting dogs, known as painted wolves, but as the weather was so warm, they must have been resting under trees, similarly African warthogs and the monkeys did not show. This did not spoil the enjoyment, as the guests focused on discussing the many subjects of the technical talks given during the 2022-23 season.

After passing the zoo we came to expansive landscaped gardens of stately mansion houses and classic modern villas, which contrasted with the industrial buildings, a power station, and historical architecture, including ornamental iron bridges such as the pillared Macclesfield ‘blow up’ bridge. Many of these villas are owned by famous musicians such as Ronnie Wood, Pete Townsend, and Noel Gallagher – if only corrosion could pay so much!

After turning at Camden, the boat made its way slowly back to Little Venice where everyone alighted, and agreed it was a very enjoyable trip, and that they looked forward to future social events in the coming years. This event was an outstanding success, and the branch would like to acknowledge the support from International Paints, without whom it would have been difficult to stage.

Reza Beheshty, Subject Matter Expert in Materials Corrosion,

Welding, & Coating, Fluor.

Onboard and Underway.

Institute News

TPS360 based in Cardiff, Wales, works with leading manufacturers and suppliers on projects for tier 1 main contractors and end user clients, to provide industrial surface preparation and coating solutions to infrastructure, petroleum chemicals, architectural finishes, and repair and restoration works. They have undertaken all types of surface preparation to meet the standards required for corrosion protection and intumescent application, including abrasive blasting (grit, shot, sponge, and plastic media), UHP, and mechanical preparation methods.

Institute News

D&P Coatings Limited

D&P Coatings, based in Ellesmere Port, England, offers an offsite blasting and coating service. Pipework, structural steel, tanks, and vessels, servicing the gas and oil industries are all processed on site at our factory in Ellesmere Port, where the directors have a combined 50 years’ experience, and the workforce have over 45 years’ experience in the blasting and coating industry.

On site facilities include a large shot blasting enclosure and a smaller booth for stainless steel items. Their facility has a loading and offloading capacity of 10T, four large coating workshops, and a large lay down area, all within their 85,000 square ft facility. The workforce has amassed a vast knowledge of the industry throughout the years, and produces the highest quality and standard of work within the specification guidelines. D&P Coatings has its own inspection department, which is accredited with ICorr and NACE. They have achieved ISO 9001, ISO14001, ISO45001 and CHAS accreditations.

Institute News

CED Day: The annual CED Working Day and Symposium, this year entitled ‘Corrosion Prevention in the 21st Century’, was held on Thursday, April 27, 2023, at the National Physical Laboratory (NPL), Teddington.

The day highlighted the need to share and transfer knowledge across all industries facing similar corrosion challenges. There were seven main talks and three working groups, led by Douglas Mills (coatings), Nick Smart (nuclear), and Steve Paterson (All Energy Group). This one-day meeting was the latest in a series of working days for the Institute of Corrosion’s Corrosion Engineering Division. Dr. Danny Burkle (Corrosion Testing Specialist – LBBC, Baskerville), Chair of CED, welcomed delegates to the meeting and introduced the speakers. He emphasised that the financial loss due to corrosion in the UK is 3.4% of GDP, or £77.5 M (comparable with defence at 2% or education at 4%). Danny thanked Nick Smart, the previous chair of CED, for his invaluable services over the past 15 years, and he presented him with a special award. Their shared vision is to bridge the gap between the CED and CSD divisions in future, to the benefit of both.

There then followed, ‘An introduction to NPL and NPL Activities’ by Gareth Hinds (Fellow and Science Area Leader, Electrochemistry Group at NPL), a past President of ICorr (2018–2020), the current President of the World Corrosion Organization (WCO), and Vice-President of the European Federation of Corrosion (EFC). Gareth outlined the history of NPL, founded in 1900, and active in corrosion research since 1924 (Guy Bengough (FRS) was an early scientist working there). Subsequently, Alan Turnbull, FRS, FREng, OBE, with 50 years of service at NPL, was introduced and applauded. The focus of government funded research at NPL is: net zero, offshore wind, nuclear waste disposal, and materials selection for these areas. Knowledge transfer includes: NPL corrosion guides, international standards, and industrial guidelines. NPL though continues to do a large amount of corrosion testing on behalf of oil and gas operators (separately, on a commercial basis).

Professor Alison Davenport (University of Birmingham) addressed the subject of “understanding localised corrosion’ and how this can improve corrosion prevention methods. The corrosion of metals in natural environments is a non-uniform process. Using synchrotron X-rays, water and metals are both penetrated, thus permitting mechanisms of formation and breakdown of passive films to be elucidated. A video study providing 3-D tomograms was shown. Rotating disc electrodes enable the growth of passive films to be followed via current transients over millisecond periods. These studies were necessary to assess the risk of fatigue failure in ageing aircraft, e.g., by atmospheric corrosion studies of NaCl deposits on Al-Cu-Mg alloys (AA2024). Similar methods were used to study the corrosion of stainless-steel containers used to store intermediate-level waste. The role of salt films in growing pits was described, along with their relationship to Pourbaix diagrams. At each point in a growing pit, it can be shown that the corrosion current is a function of metal ion concentration and the electric field through the droplet.

Dr. James Hesketh, (Principal Corrosion Science Consultant at Jacobs) spoke on ‘The corrosion of canisters during interim and deep geological disposal of radioactive waste’. There are three levels of radioactive waste: high, intermediate, and low (HLW, ILW, and LLW). Containers for LLW and ILW include unshielded, thin-walled stainless steel, concrete fabrications, and robust cast iron canisters, which have greater impact and fire-damage resistance. Intermediate storage items have been subjected to atmospheric corrosion over several decades. Key environmental parameters are % RH, surface chloride concentration, and time of wetness. Future deep geological disposal will provide permanent, safe disposal. One specification is KBS-3. However, a Swiss concept enabled progress to a more advanced stage. All present designs make use of a multi-barrier approach, comprising copper/carbon steel, with predicted lifetimes >10,000 yr. Despite the complexity and time-variation of corrosive environments, two distinct phases may be identified – early, ‘oxidic’ and long-term, ‘anoxic’. In-situ experiments involving boreholes were then outlined.

Alyshia Keogh (University of Manchester – PhD student) discussed her current research, on the ‘Effect of microstructure on localised corrosion and atmospheric stress corrosion cracking of 15-5PH stainless steel’. The type of microstructure influenced the susceptibility and was very dependent on the ageing temperature, 450 °C, 540 °C or 650 °C. Microstructural characterisation was carried out by STEM/EDX, and differences in pitting behaviour were assessed using double loop electrochemical potentiokinetic reactivation (DL-EPR), which found a linear trend in degree of sensitisation with ageing temperature, and which correlated with the increase in the presence of Cr carbides. Electrochemical noise measured by galvanically coupling dissimilar microstructures suggested that the higher temperature ageing treatment produced the most metastable pitting events. This may have a higher probability of transitioning to stable pitting. Four-point bend specimens with Cl- salt deposits exposed to controlled temperature and humidity revealed that higher ageing temperatures were more resistant to cracking. The mode of cracking changed from intergranular at 450 °C to mixed-intergranular and transgranular, at 540 °C, whereas no cracks occurred in samples aged at 650 °C.

After an excellent lunch there followed several further talks, including one by Roger Francis himself, together with a presentation of the Paul McIntyre Award to him, a very worthy winner. This award is among ICorr’s premier awards, and is presented to a senior corrosion engineer, who, as well as being a leading practitioner in their field, has advanced European collaboration and international standards development.

Roger has been a corrosion engineer for over 45 years, working in the fields of marine corrosion, desalination, sour oil and gas corrosion, mineral processing, and the chemical and process industries. He has published over 100 technical papers in all these areas, written six books on various aspects of corrosion, and jointly edited three others.

Dr. Steve Paterson, (Materials and Corrosion Adviser, Arbeadie Consultants Ltd.) then presented on ‘Applying materials experience from oil and gas production to carbon capture and storage’. Carbon Capture and Storage (CCS) processes prove challenging in so far as the CO2 source may contain impurities, and processing is determined by the level and type of these. Problems encountered in transporting the fluid include liquid dropout, corrosion, and running ductile fracture. Joule-Thomson cooling causes low temperatures with an attendant lack of toughness, the preferred option is to avoid drop-out. Essentially, it is important to consider transients/unstable conditions when assessing processes and defining CO2 specification limits. Also discussed were low temperature brittle fracture and hydrogen-related cracking mechanisms, Stress Corrosion Cracking (SCC), the use of corrosion-resistant alloys, the application of downhole barrier valves, and non-metallic materials.

Dr. Jonathan Mann (Nuclear structural integrity engineer, Jacobs) gave an entertaining but most important talk entitled ‘How to make trends and influence people’ which focused on how fatigue damage is increased by corrosive environments, and is a key consideration in numerous industries, including nuclear. Fatigue crack growth (FCG) studies had been initiated by Rolls-Royce and supported by Jacobs. Current predictive methods are fairly simple, providing over-conservative results. An improvement was to move to a better model, that reflected real behaviour. The ASME Environmental Fatigue document provides fatigue and FCG data for austenitic stainless steels in PWR water (low dissolved oxygen), and an equation relating fatigue life to temperature, strain rate, and oxygen concentration was given. Other factors affecting fatigue life include, varying amplitude, load, multi-axial loading, surface finish, material variability, non-isothermal loading, and thermal gradients. Consequently, rigs have been designed to investigate any type of waveform over a wide-range of temperatures.

Dr. Roger Francis, (Director at RF Materials) gave a resume of ‘The limits of copper alloy and stainless-steel heat-exchanger tubes’. Common alloys used for heat exchangers are, copper alloys (w/o), Al-brass, 90Cu/10Ni, 70Cu/30Ni, and 66/30/2/2 Cu-Ni-Fe-Mn, plus stainless steels, 304L, 316L, 20Cr/18Ni/6Mo; 2304 and 2205 duplex plates, Z100 and 2507 super-duplex. Erosion-corrosion and pitting/crevice corrosion are encountered.

With Al-brass erosion ’horse-shoe going upstream’ defects occur at velocities of 1.5 – 2.0 ms-1. Where seawater contains chlorine to prevent fouling, minimal concentrations should be used. If silt is present, corrosion rates rise rapidly with silt content. However, titanium shows no erosion-corrosion over the entire range of silt levels. For copper alloys, crevice corrosion is not a significant problem, and pitting corrosion is not problematic in fresh water. Sulphide ions at 0.1 mg/l cause pitting corrosion but may be mitigated by acid-cleaning. Super-duplex steels have demonstrated excellent corrosion-resistance since the early 1990s.

Dr. Anthony Setiadi (Chief Consultant / Associate Director – Wood Thilsted) presented finally on the ‘Benefits of using corrosion protection for offshore wind’. Monopiles (MPs) widely used in the supply of renewable energy presently range from 8–10 m diameter and 90 m high. However, for future MP’s, 15 m diameter and 120 m high are envisaged. MPs operate in 15 – 60 m water depth, deeper waters require jackets or floating foundations. In any case, increasingly large surface areas are involved. Corrosion protection via materials selection, corrosion allowances, coatings, and CP for sea-water immersed areas, were discussed. Coatings and cathodic protection support a large decrease in the tonnage of steel required for these structures. Percentage steel tonnages were compared to a ‘base cost’ and tables were presented for 25, 30 and 35-year timescales for C1, C2, C3, and C4 environments.

Typical losses (kg y-1 m-2) ranged from 1.56 in C5 to 0.624 in C4 environments. It should be noted that the coating type can impact corrosion protection very significantly as does control of application at build. Finally, the need to consider the different climates encountered was discussed: tropical, sub-tropical, temperate and arctic.

It was possible later in the day for participants to visit the extensive corrosion laboratories of NPL.

All CED presentations will be uploaded to the ICorr website for members to view and download. The three working groups will continue to advance their activities and will announce dates for further meetings in due course. To find out about next year’s CED event, or if you are interested in attending, speaking, or exhibiting, contact Dr. Danny Burkle, at danny.burkle@lbbcbaskerville.co.uk The CED is actively recruiting for a vice chair to assist Danny with growing the division. If this is of interest to you or a colleague, please contact Danny and let him know. Corrosion Management is most grateful to Dr David Nuttall, FICorr and Dr Douglas Mills, FICorr, for providing this event write-up.

Presentation to retiring CED Chair Nick Smart, By Dr Danny Burkle, New CED Chair.

Professor Alison Davenport (University of Birmingham) addressed the subject of ‘understanding localised corrosion’.

Presentation of the Paul McIntyre Award to Dr Roger Francis by Stephen Tate, ICorr President.

Dr Gareth Hinds – Fellow and Science Area Leader, Electrochemistry Group conducts a tour of NPL facilities with ICorr guests.