Institute News

On June 22nd and 23rd, the North-East Branch, in conjunction with NEIMEE, held a highly successful conference and exhibition entitled ‘Integrity Engineering for a Sustainable Future (IESF) at the magnificent Neville Hall in the centre of Newcastle. Over 60 guests attended this special event, coming from all over the UK and as far afield as Scandinavia and The Netherlands. All enjoyed a full day of presentations, followed by field trips on the second day. In between the work, there were plenty of opportunities to network, and a gala dinner was held at the end of the first day and greatly enjoyed by all.

The conference was held in the well conserved, grade II listed, Neville Hall, which dates back to the 1860s. Neville Hall is the head office of the North of England Institute of Mining and Mechanical Engineers (NEIMEE) which partnered with the NE Branch in hosting the conference. The rooms in Neville Hall still have their original features (see photos). The lecture theatre and library are particularly impressive, and not many industrial conferences have been held in such remarkable buildings.

Past President Trevor Osborne opened the conference and was closely followed by keynote speaker Prof Jon Gluyas of Durham University, who gave an insightful and humorous presentation entitled “Energy: a sustainable future built on an unsustainable past” commenting on the links between population growth and energy requirements and commenting on possible sustainable sources of the energy required.

A busy day saw a further nine presentations (see table), informatively covering a wide range of topics from carbon capture and storage to wind energy. Topics included new construction, repurposing’ and repair. Old and new technologies were

discussed in terms of sustainability, from solid anodes to drone repair of wind tower blades.

1. Energy – A Sustainable Future Built on an Unsustainable Past. Prof. Jon Gluyas – Durham Earth Sciences

2. CCS Corrosion and materials selection overview and challenges, the approach of an integrated energy company. Roberto Morana – BP – Net Zero Teesside

3. How do you take sustainability into account during design? Birit Buhr – European Energy

4. Advances in wind blade coatings and testing. Edvard Daehlen – Carboline

5. Mitigating Environmentally and Sustainability Impacts of Cathodic Protection in Seawater. Winston Shepherd – Impalloy Ltd

6. Flying Drone Repair of Wind Turbine Blades – Better, Safer and Faster. Chris Kirby – Reblade

ApS – Denmark

7. Addressing hydrogen pipeline repurposing safely & economically. Daniel Sandana – Rosen Group

8. Non-Destructive Testing Challenges in the Net Zero World. Dr Patricia M Conder – ESR Technology Ltd

9. Development of coatings to last the life of the Asset. Willem Horn –AkzoNobel

10. Why paint when you can patch with Easy Qote. Dinko Cudic – Seal for Life Industries

The first day culminated with a conference dinner in the old library, a magnificent room, with books stored behind wooden doors and a gallery reached by ladder to access books stored higher up on the wall. An opening address was given by Trevor Osborne and the meal closed with some final encouraging words from current ICorr President Stephen Tate.

The second day was made up of two site visits in the nearby town of Blyth. Ore Catapult is the UK’s leading technology innovation and research centre for offshore renewable energy. The visit was hosted by Tom Chaplin, Marketing Manager at Ore Catapult.

Their modern facility in Blyth includes an impressive 100-metre-long testing hall capable of testing the biggest wind blades, with plans to increase the capacity as blade size continues to increase. The site also has test facilities for wind turbine powertrains with a capacity of up to 15 MW. Away from the wind turbines themselves, they also have the DARE Digital, Autonomous, and Robotics Engineering Centre.

The second tour was to Bates Colliery, hosted by Charlotte Adams, Principal R&D Manager for Mine Water Heat at The Coal Authority. Bates Colliery is one of a network of disused mines in the north-east where water is being pumped out in large quantities to control the water levels in the mine network.

Using solar power, the water pumped up is treated, settled, and filtered through natural reed beds before being released into the River Blyth. Due to the depth of the mine, the water comes up warm and could be used to generate 5 MW of geothermal energy—a good example of a sustainable legacy from what is considered a polluting industry. Going forward, it has the potential to develop 5 MW of electricity from the groundwater, enough to power the local school.

Ore Catapult is the largest R and D Test centre for wind turbines in the world, currently testing 100 m blades but looking to increase length capacity by 50%. Already, it’s so large that you can drive a double-decker bus in at the end. An incredible facility that tests gearboxes the size of which you can’t imagine, and to see them close-up was breath taking.

This is all wrapped up by “Energy Central,” a partnership of all the Net Zero related businesses; one of the initiatives being to establish and promote local skills to meet the demand.

A fantastic example of the transition from ‘Unsustainable to the Sustainable’.

The North-East Branch Committee wishes to thank all attendees and organisers who made this such a successful and memorable event and hopes the conference demonstrated the opportunities for ICorr in the North-East. A special welcome also goes to our new NE Student ICorr members who actively participated on both days.

After a short summer break, the committee will turn its thoughts to some of the many questions asked after the conference: “Will there be another?” Can we have a NE Christmas Dinner?” “When are the next technical events?” Any interested sponsors should contact nechair@icorr.org

The NE Branch would like to thank all of the sponsors and exhibitors who made the conference possible; Carboline, AkzoNobel, Reblade, Safinah, Metec, Corrosion Integrity Management and The Royce Institute.

*Organising Committee, Matt Fletcher (Chair), Josie Watson (Treasurer), Bruno Ravel, Barry Turner, Patrick Johnson, Simon Daly, Andrew Dobrzanski and David Mobbs with a special thanks to Dr David Bell who expertly controlled all the IT and recordings on the day.

All of the presentations can now be viewed on the ICorr or NEIMME websites.

Please refer to the ICorr Website: North East Branch – Institute of Corrosion (icorr.org) under Local Technical Programme 2023.

CAPTIONS:

Keynote speaker Prof Jon Gluyas of Durham University.

Networking with Exhibitors.

Summary of Technical Presentations.

Conference guests at Dinner in the Magnificent Neville Hall Library.

Guests await Site Visit Registration at Newcastle Central Station

Delegates at Ore Catapult site visit outside the Blade Test Hall and nearby Monopile Testing Facility.

Pumps at Bates Colliery.

Reed Beds before River Blyth discharge.

The Digital, Autonomous and Robotics Engineering (Dare) Centre at the Offshore Renewable Energy (ORE) Catapult’s testing facility in Blyth.

Institute News

Dear Members,

A very special welcome to our new Overseas Members and our new Student Members who recently joined us. Please let me know if there is anything at all l can assist with to improve your membership experience with ICorr.

Our student Bursaries Scheme with The University of Manchester is now approved and will commence this September.

We are also working hard behind the scenes to offer a wider range of Training Courses, and to expand our technical programmes for 2023-2024, and with that in mind, l must mention our newly launched Microbiologically Influenced Corrosion training course. You will find a poster for this in your magazine, please display it in your workplace for others to see. Thank you. Details of our Corrosion Under Insulation (CUI) course will also be announced shortly.

A lot more has happened since the last issue, in June our Northampton HQ hosted the Engineering Council Licence review for our Chartership Scheme, with a great result from that audit. Under the skilled eye of David Harvey, we expect to move forward with ICorr’s own CEng Direct Scheme in 2024.

Also at HQ, our Correx team is preparing to roll out the new ICATS Apprenticeship Scheme, with Kevin Harold working hard to launch it soon. The first two ICATS apprentices were tested

on July 12. https://www.icorr.org/correx/

Our NE Branch Sustainability Conference was a hugely successful event in Newcastle on June 22nd and 23rd, a true showcase for all that ICorr sets out to achieve in the fields of corrosion education and industrial partnerships. Very well done to all the NE committee members who have great plans going forward.

On June 28, the North-West Branch held their AGM and hosted an industrial visit to the Sherwin-Williams paint facility in Bolton. Interaction with the industry like this keeps everyone up-to-date and helps our branches thrive. A special thanks to Greg and all involved there.

On August 22, we will once again be offering our Corrosion Awareness Day in Aberdeen, which has proved very popular in previous years. See our events for August 2023 – Institute of Corrosion (icorr.org).

Finally, a reminder for our Corrosion Science Division’s 64th Corrosion Science Symposium (CSS) at the University of Bristol on September 10–12, 2023, including the UR Evans Award and Plenary Lecture. We do hope you can support that.

All our branches are becoming increasingly active in the U.K., and we hope to have some Overseas offerings soon too!

We very much look forward to you joining us soon, either in-person or online, for our 2023- 2024 ICorr Technical Sessions run by our UK branches.

Our ICorr calendar is regularly updated,

https://www.icorr.org/events/

I hope you will maximise the benefits of your membership by participating in these fantastic networking events.

Wishing you a great summer break.

Stephen Tate, President Institute of Corrosion

Institute of

Corrosion

President,

Stephen Tate

Institute News

Welcome to the July-August issue of the magazine. It has been a few months since I joined the Institute of Corrosion team, and I am constantly looking for news and articles that may interest you.

I want to express my gratitude to Stephen and Brian for helping me on my journey so far.

This issue brings you all the magazine’s regular columns, plus a special technical article on Microbiologically Influenced Corrosion (MIC) by Tony Rizk. There is also a case study on chloride SCC of stainless steel, “Chloride Induced Stress Corrosion Cracking of Repaired Pipe Elbow from an Oil Refinery: Forensic Analysis”, by Chidambaram Subramanian.

The 10th anniversary of International Women in Engineering Day was celebrated on June 23 in the UK, and throughout the world, with the theme“Make Safety Seen”, and we have included a report on this for you.

We want to provide engaging and informative content for our readers, and your participation in maintaining the high standards of the magazine is crucial. Your suggestions and feedback are very important to ensure that we deliver a magazine that will engage and interest you. I can be contacted at,

editor@icorr.org.

Dr Shagufta Khan, FICorr Consulting Editor

Aberdeen Branch, Institute News

On Tuesday 30th May 2023 the branch welcomed David Wickham and Chris Fyfe of AkzoNobel, who gave a talk on Maintenance and Repair Solutions for Damaged or Aged PFP. This was a hybrid Joint ICorr/AMPP event with over 40 Attendees.

The branch was very pleased to be able to return to the Palm Court Hotel on this occasion, a place with which it has so long been associated.

David Wickham is a practising fire and explosion engineer with 24 years’ experience in the field of passive fire protection. He is a Chartek fire engineer / technical manager, Fire Protection, holds a Master’s degree in Fire and Explosion Engineering from the University of Leeds, UK (2002), and is also an ICorr PFP Epoxy Coating Inspector Level 3. David is currently the Fire Protection Technical Manager at International Paint (part of AkzoNobel) a member of the Institution of Fire Engineers (MIFireE), and also a visiting lecturer on the MSc course, presenting on ‘Aspects of Fire Protection in building design’. He is responsible for providing technical support for upstream and downstream oil and gas projects, fire protection in the Built Environment and ‘special projects’ and has particular expertise in the area of ‘fire testing and evaluation of test data’ to support accreditation and certification of products to global fire test standards. Along with fire protection in Maintenance and Repair (M&R), he is currently a project leader looking at solutions for fire protection for battery electrical energy storage systems (BEESS).

Chris Fyfe is a PFP Senior field auditor and coach. As a Chartered Scientist, Senior Corrosion Technologist, and Fellow of the Institute of Corrosion, Chris also holds an AMPP Senior Level 3 coating qualification. He has extensive knowledge of both new build and maintenance projects ranging over 35 years with several operators and has been employed as a surface protection specialist and fabric maintenance coordinator, understanding first-hand the many challenges for maintenance and repair.

Maintenance and Repair Solutions for Damaged or Aged Passive Fire Protection (PFP)

Many facilities have reached, or are reaching, the end of their original design life. However, in many cases, these facilities are required to continue operation beyond this time. This poses many operational health and safety issues, among them the efficacy of in-situ passive fire protection (PFP) that may have been applied when the facility was first commissioned. In many cases, this PFP will have deteriorated to a point where it may not provide the required protection in the event of a fire. Where this damage may be extensive, this can create difficult economic (M&R) decisions to overcome. M&R resources are not limitless, and where repair priorities have been identified, selecting the most efficient repair solution becomes important. The two most important requirements are demonstrable fire resistance performance and application costs (both materials and installation). In many cases, the latter may far outweigh

the former. Costs of installation may have a significant bearing in active process areas subject to limits on operational activities (such as surface preparation).

On older upstream and downstream facilities, in-situ PFP may comprise structural steel encased in dense concrete, Light-Weight Cementous (LWC) or other systems. Where these types of PFP are cracked or damaged, they may expose the substrate, leading to accelerated corrosion, operational integrity concerns, and dropped object hazards, in addition to concerns about continued PFP functionality. The true extent of all underlying corrosion may not be immediately apparent, and removal or replacement is normally the best course of action.

As a company, AkzoNobel recognises how M & R activities surrounding PFP performance are integral to maintaining plant operational safety by allocating limited M and R budgets more effectively. – this includes identifying and prioritising the damage of most concern (fire integrity assessment – what damage level will not meet the site fire scenario) and providing repair materials that: have proven fire resistance performance, and offer ease of installation.

The company has identified various schemes for items that need PFP repair:

• Scheme 1 – PFP adequate for the fire case – repair solution to arrest rate of corrosion.

• Scheme 2a) – Risk of dropped object hazard – repair required to remove the hazard and ensure repair is PFP functional.

• Scheme 2b) – loss of PFP functionality and corrosion concern – tested repair solution that reinstates the PFP and stops advancement of corrosion.

• Scheme 3 – ‘special case’– repair acceptable based on other criteria or requiring specific fire testing.

Examples were given of the putty and mortar products used in the repairs onto primed or prepared surfaces and their characteristics:

• MP: A single component mouldable putty compound.

• SFR: Single component structural grade mesh-free repair mortar.

• No tools required – MP can be applied direct from the pail by hand.

• SFR only mixing with water required – and can be applied direct by hand.

• Both the above products are completely non-hazardous and repairs can be completed without any hot work permits.

For Missing and Cracked PFP – Concrete / LWC:

• SFR product can be used; this product has been both jet and pool fire tested for over 180 minutes.

• MP is an alternative and this is jet and pool fire tested to 120 minutes. The products can fill cracks up to 50 mm wide and voids up to 900 cm2 and are Lloyds / UL verified.

For the repair, the edges of the concrete to which it will bond need to be checked for contaminants, and wire brushing should be used to clean the surfaces. Any exposed steel needs to be cleaned and an approved surface tolerant primer, such as 670HS, applied. Where the base material is concrete, the cementitious edges should be wetted to improve adhesion, and PVA glue should be used as an additive agent to help bond. The Interkote material needs to be brought flush with the concrete for this repair, no wire netting is required.

On Tuesday 28th March 2023, the branch meeting welcomed Dr Kevin McDonald – Sonomatic, with a talk entitled ‘Effective pipework analysis and inspection planning using Digital Twins’.

Kevin is a principal integrity engineer within Sonomatic’s integrity team in Aberdeen. He is a mathematician with a PhD in computing science. He has extensive experience in data analytics and inspection planning for pipework, pressure vessels and pipelines, co-authoring the recommended practice for Non-Intrusive Inspection (NII) as applied to pressure vessels. As well as integrity consulting, he is involved in the technical capability development for Sonomatic’s integrity team with a focus on statistical approaches. Recently, he has been involved in developing a statistics-based method of inspection planning and evaluation applied to subsea pipelines for a major operator.

Effective pipework analysis and inspection planning using digital twins

The integrity of pipework is essential for the safe and reliable operation of process plants. Inspections are traditionally performed at large numbers of individual test points, with results recorded in an inspection database. In general, this data is subject to relatively simple analysis, with the results used in integrity management decisions. However, this traditional approach can be heavily influenced by poor processes, outliers, or errors for example: incorrect entry of results, not recording higher thickness readings than those obtained previously, and inconsistencies in inspection location, are some examples of how error can be introduced into this process. This could lead to poor integrity decisions and misinterpretation of wall thickness trends. Analysis of pipework data, which is in general restricted to the difference between two thickness readings relative to the dates the readings were taken, can then be driven by measurement error.

Kevin proposed a novel alternative is to consider historic datasets as a whole and look at long-term statistical behaviour to consider how corrosion could be affecting pipework. This approach looks at whole datasets to determine behaviour before considering any sub-groupings of data points that are showing similar behaviour. The Sonomatic developed SPiDARS software accommodates many data formats. Boxplots can be used to display the whole of an inspection history in one view. In this example a normalised view allows all schedules of pipe to be compared. Boxplots can also be used to provide a quick overview of long-term trends (up or down) and can show stability over several years or highlight changes graphically that cannot be seen from data alone, due to spreads and errors affecting judgement.

The illustrated example shows a downward long-term trend indicative of increased corrosion activity. It provides context and a jump in the final result, indicating replacement of the pipe. Data can also be grouped for pipes by diameter which can show that larger pipes seem to have more corrosion issues than smaller ones, or by pipe configuration feature type such as bends, caps, reducers, or straight sections to search for trends.

Corrosion rates determined from Non Destructive Testing ( NDT) generally trend toward wall loss percentile values as the principal criteria. Looking at group trends mitigates measurement error and gives more accurate short and long-term corrosion rate estimates. Any point showing a concerning trend can be extrapolated to predict when an alarm limit may be reached. Corrosion rate data can be plotted in different ways to try and identify issues such as localised and unusual corrosion rates. Lots of data on wall thickness measurement may just behave in a linear sense such as presented here for selected years and locations – nothing unusual is shown and general corrosion is happening at expected rates.

Sonomatic have developed 3 different inspection planning methodologies. The Type 2 methodology was further discussed with steps detailed below:

• Define corrosion state (is it what we expect to find)

• Define a corrosion coverage from previous results

• Define extent of corroded material

• Define thresholds of concern (based on historic results)

• Consider points flagged as over/under inspected

• Consider expected corrosion mechanisms that have a bearing on applied technique

• Define detection threshold

• Define probability of detection (POD)

This approach is underpinned by simple and effective access to the data, which is linked to a 3D mini digital twin.

The mini-Twin also hosts a variety of data, as well as individual test points, corrosion maps, and can house inspection histories, photographs, and further data analysis of corrosion rates, fitness for service etc. 3D is used to present data in efficient ways to quickly provide an overview of the health of the pipework circuit, for example inspection frequency, inspection count, corrosion rates, all of which is valuable information for engineers and asset stakeholders.

For identified ‘Dropped Object’ hazards: the item can be encased using GRP wrap + Chartek 7E paste filler at 2mm or an encasement system pipe shell or epoxy box is used with product Chartek/Benarx, for which there are simple procedures (see image below).

Systems were also discussed for upgrading 3 sided beams using either Chartek 2218 at a 6mm thickness level to primed steel areas and overlapping the cementitious edges either side, or alternatively MP can be used and applied to steel surface prepared to SP11 finish. This material can be rolled out at a 30 mm layer thickness that adheres to the prepared steel. This solution is good for support beams for walkway grating supports.

Studies were also presented on fire testing of the repaired products to given standards.

Fire Testing of Repaired Products

The fire performance of both Interkote MP and SFR has shown excellent fire performance (in some cases better) than the in-situ LWC or concrete. IK MP was verified in EPFP testing (TN to update). Technical note F_021 may be deployed to select the best repair solution to meet fire protection requirements.

AkzoNobel’s PFP repair solutions extend the available range of Chartek solutions for maintaining damaged or failing PFP. The focus is on simple repairs to damaged LWC and concrete PFP (EPFP to be added for IK MP) for application simplicity and cost-effectiveness. The intention is to give customers confidence that repair solutions will provide the required fire resistance and repair integrity. All the repair solutions are backed up by third party approvals.

The branch held its AGM on June 27, 2023, and unanimously elected Adesiji Anjorin MSc, BEng, CEng, MICorr, MNSE, COREN of ENGTEQ as its next Branch Chair and Mei Ling Cheah AMPP Certified Corrosion Specialist, BEng MSc PhD CEng CSci FIMMM FICorr, of IMRANND as

its new Vice Chair.

The branch was sorry to see the departure of its 3 times Chair, Dr Muhammad Ejaz, PhD, CEng, FICorr, FIMMM, AMPP Corrosion Specialist, after 13 years of service, and a presentation will be made to him at a later date, once he has settled into his new home in Abu Dhabi.

On the same day, the branch also held an online event entitled – Direct Assessment for Unpiggable Pipelines, which covered both Internal and External Corrosion threats, and was led by Dirk L.Van Oostendorp.

Dirk is Director of Engineering and Technical Services for Corrpro, based in Houston, TX and Van Oostendorp has more than 40 years of global experience in all aspects of pipeline and structural integrity, encompassing cathodic protection, corrosion control, material selection, protective coatings, inspection technologies, and risk assessment. More recent experience includes integrity monitoring, failure analysis, and pipeline integrity issues. He holds undergraduate and graduate degrees in chemical technology and physical chemistry. He is a Fellow of the Royal Society of Chemistry, a Fellow of the Institute of Corrosion, and a NACE Corrosion Specialist. He was a member of the original INGAA-Battelle team that developed what has now become the Direct Assessment Methodology (DAM).

This presentation discussed the four essential steps of the Direct Assessment methodology, highlighted success factors, shared results from actual projects, and assessed the various challenges that can be encountered during implementation.

The majority of North American natural gas transmission pipelines were not constructed to permit inspection using intelligent tools (ultrasonic, magnetic flux leakage). This was due to the lack of launching and receiving facilities, but also throughput requirements, varying (telescopic) diameters, short radius or wrinkle bends, reduced port valves, or branch connections. In order to adequately ensure the structural integrity of these pipelines, some alternative forms of condition determination and evaluation was required. The Interstate Gas Association of America, together with the

Gas Technology Institute, assembled an expert team to address this

issue. The result was the development of an alternate inspection methodology, coined Direct Assessment, which made use of a combination of proven techniques.

Based on Federal laws signed in 2001, pipeline operators in the USA were required to develop a proactive Pipeline Integrity Management Plan (IMP) intended to manage risk and protect the public in areas near operational pipelines. Inline inspection (ILI) was the preferred methodology to inspect pipelines, and hydrostatic testing was the alternative.

AMPP, as the industry representative, was called upon to develop standard procedures to govern the correct implementation of Direct Assessment and provide guidance for practitioners. Early in the development process, it was noted that the methodology needed to be segmented, in order to address differing integrity threats, and External Corrosion Direct Assessment (ECDA), Internal Corrosion Direct Assessment (ICDA), and Stress–Corrosion Cracking Direct Assessment (SCCDA) resulted. NACE initially published RP0502 for ECDA in 2002, and other standard practices for the other methodologies followed. As living documents, these standard practises are subjected to peer review every 4–6 years.

Dirk very clearly explained the details of the processes now being followed and how supplementary investigations may come into play as the assessment proceeds.

Both the AGM and the June presentation were fully recorded and are available at: https://youtu.be/B9_4DHySnmg and at ICorr Aberdeen – YouTube

Abstracts of potential papers for the Aberdeen Technical Programme are always welcome, and anyone wishing to present should correspond with the 2023/2024 Technical Programme Co-ordinator: Adesiji Anjorin anjorin@gmail.com

Further Information about the Aberdeen Branch, and past presentations, may be found on their website page: Aberdeen Branch – Institute of Corrosion (icorr.org) and to join the Aberdeen Branch mailing list, please contact: icorrabz@gmail.com

The Branch has the following upcoming conference event for which attendance is strictly limited to 50 persons: This Event will include a number of Practical Demonstrations.

On 22nd August, the branch will hold its Corrosion Awareness Day at Rysco, Bridge of Don, Aberdeen, from 9-5pm

Attendees (and their respective companies) will gain an understanding of the fundamentals of corrosion science and engineering; which can give insights into technical corrosion / materials challenges, improve their understanding of corrosion processes, raise their awareness of corrosion management, and provide confidence to attendees when discussing corrosion-related issues and concerns; and sales people will gain insights into the corrosion problems and needs of their customers by enabling relevant technical conversations with clients regarding corrosion issues.

Registration for this Event closes on 15th August 2023.

Please see the ICorr Events Calendar for all the latest information.

TABLE:

ITEM F EXISTING PFP / SUBSTRATE DEFECT / ANOMALY TYPE

Concrete Or Cementiltious PFP / Carbon SteelDropped Object Hazard

Repair System Installation Photos/Drawings Limitations / Notes

Chartek 7E

& GRP Overwrap a) Damaged/loose concrete/cementitious should be left in place.

b) Cut the GRP material so that there is a minimum 50 mm overlap around the perimeter of the section being wrapped.

c) The GRP should be pulled tight around the damaged PFP and then left to cure. Cure time is dependent on good light levels which should be between 1-2 hours. Any top protective layer should be removed to leave a matt surface finish.

d) Once the GRP is fully , apply Chartek 7E at minimum 2 mm directly to the matt surface of the GRP. No primer required. Refer to the GRP manufacturers manual for application instructions.

Benarx Boxes & Pipe Shells a) Damaged/loose concrete/cementitious should be left in place.

b) The Benarx box/pipe shell can be fitted around the loose PFP and held in place using integral toggle & latch fasteners or stainless steel bands. Installation of Benarx solutions will require accurate measurements to ensure

correct fit.

CAPTIONS:

David Wickham and Chris Fyfe of AkzoNobel.

PFP Interkote Repair Solutions – Site in Belgium.

Failed LWC on vessel skirt.

Cut out defective LWC Simplehand application of KSFR.

Interkote SFR finished repair.

Interkote SFR@50/28mm Concrete/LWC repair –jet fire testbox.

InterkoteSFR –post jet firetest.

IMAGE Left to Right – Aberdeen Committee Members at June AGM – Mei Ling Cheah – New Branch Vice Chair, Yunnan Gao – ICorr Vice President, Nigel Owen – External Secretary, Lian Ling Beh – Internal Secretary, Leela Ramachandran – University Liaison & CPD Officer, Adesiji Anjorin – New Branch Chair and Stephen Tate – ICorr President.

Dirk L. Van Oostendorp, Director of Engineering and Technical Services for Corrpro.

Institute News

The first of the series of YEP-AMPP Journals, by Christopher Slater, Project Engineer, STORK, Aberdeen, is given below.

The 2022 Young Engineer Programme (YEP) consisted of 9 evening lectures presented by specialists in their field, to provide technical competency and knowledge across the field of asset integrity to delegates, combining with the Aberdeen branch technical programme.

Subsea 7 loaned their training facility for this purpose. that were covered during the 2022 programme:

• Fundamentals of corrosion

• Cathodic protection

• Coatings and linings

• Corrosion under insulation / fire proofing

• Integrity management / fitness for service

• Materials / welding

• NDT and corrosion monitoring

• Production chemistry / chemical treatments

• Presentation skills

The case study presented a scenario whereby we were engaged by a mock integrity services contractor to advise an international company that is a newcomer to the operation of production facilities in the UK sector of the North Sea. This consisted of analysing the scenario and current integrity status of the pressurised systems on the mock platform through the evaluation of the provided data and performing an initial risk assessment to identify key threats to the mechanical integrity of the pressurised systems. The brief to develop our proposed application of a systematic methodology to manage corrosion and surveillance activities allowed for approaches to prolong service life, the use of innovative solutions, the assessment of material options for the new pipeline, and the possible impact of H2S on operations to be explored and practical experience of these aspects to

be achieved.

In the accumulating case study and later presentation, we were guided to develop this in a way that gave us valuable experience of approaching/dealing with the mock prospective client, including the production of an overall high-quality presentation with a balance of presentation skills and team coordination through presentation, all of which were developed through delivery and exposure to the task.

Throughout this programme, the technical lectures and opportunity for direct implementation of learnings from lectures have given me invaluable exposure to fields of asset integrity that I hadn’t previously been exposed to, as well as providing opportunities to develop further practical knowledge of aspects I am familiar with.

I believe that this programme has given me a stepping stone’ towards further progressing my career within asset integrity and has opened new career avenues on the back of it.

AMPP Member Leadership Development Programme

We all had the opportunity to enrol in AMPP’s Member Leadership Development Programme (MLDP) ahead of the conference. The intent of this programme was to provide enhanced leadership skills and training to members who may have an interest in serving in upper-level member leadership roles within the organisation in the future. The programme was led by Kim Ray, the Director of the EMERG Student Outreach Programme at AMPP, in partnership with Lauren Kaufman Blachman of Kaufman Blachman Consulting. The programme consisted of a series of learning sessions. On the Sunday preceding the conference, a full-day in-person event was organized, followed by five monthly online sessions. We have also participated in additional online meetings in which we, within groups of other participants on the programme, will later present the culmination of our work on a case study to the Joint Executive Committee of AMPP.

The leadership programme included training sessions that help provide a more in depth understanding of AMPP, its governance structure, the strategic plan, as well as its products, programmes, and services. In addition, participants would also intensify their own leadership skills with sessions in emotional intelligence, change management, communication skills, presentation skills, and much more. This special event kicked off on the first day of the conference. The morning session included an introduction to some members of the AMPP Joint Executive Committee and AMPP Chief Staff Officers who were available to come along to share their welcomes and provide positive insights into the programme. This initial in-person session, among other team building activities, included an Emotional Intelligence workshop providing a depth of personal insight in order to enhance our ability to use emotional intelligence to feel more positive and be a more effective influence throughout our personal and working lives. During this, there were several interactive break-out activities allowing for the opportunity to get acquainted with the American and other international participants and build relations that would be carried throughout the conference trip and furthermore into the rest of the MLDP programme.

This experience left me feeling much more confident to go forward with my leadership and management skills, as I was able to develop effective communication skills and an understanding of effective leadership. I feel much more confident going ahead as a leader to manage change. Also I have gained experience on how to navigate situations with heightened emotions effectively, being able to read a room and recognising what actions to take, through better emotional intelligence, depending on scenarios faced in professional and personal situations.

AMPP 2023 Conference + Expo

Due to the wide array of topics associated with materials protection (corrosion control and protective coatings), I planned my schedule to cover further development and advanced technologies in the field of plant inspection but also include a range of topics across the broader field. Kicking off on Sunday, the first day of the conference, proceedings consisted of a Coatings 101 workshop, which gave basic awareness of a typical protective coatings project, from understanding the need for a project and the selection of coating criteria to the unique challenges faced in the industrial coating industry. The afternoon consisted of a symposium on “Digital asset transformation: application of data science and analytics for corrosion management” – featuring a presentation on “eddy current array technologies, the utilisation of digital twin technologies for predictive corrosion and proactive management, and overviews of operators” developed holistic corrosion management software and dashboards. In the evening, we attended the opening reception for the conference. Monday included several symposia, including “Facilities integrity: day 1” (including presentations on tank linings and composite repairs), “Corrosion under insulation” (including presentations on the utilisation of on-line inspection and monitoring solutions for CUI management), and “materials and cost of corrosion” – including effective service forecasting assessments and initial material selection for the improved lifecycle and project costs. In the evening, we attended a meal with some senior ICorr members who attended the conference, including Stephen Tate (President), Gareth Hinds (Past President), Danny Burkle (CED Chair and past YEP attendee, from 2018’s winning team), and also Peter Elliot (former UMIST lecturer). Tuesday presented a busy day visiting symposiums on “sweet and sour corrosion”, “corrosion management”, “facilities integrity: Day 2”, “materials and integrity in oil sands”, “marine coatings and corrosion”. The most notable and interesting presentations I attended included a talk on “the importance of leadership in corrosion management” which stressed the importance of leadership as opposed to management in the success of a corrosion management programme. Another highlight was a presentation where a failure investigation was shared summarising the step-wise failure analysis to understand intergranular stress-corrosion cracking (IGSCC) failure mechanism observed for carbon steel pipelines and piping, believed to be related to the presence of mineral wool insulation of a certain vintage. Also included in these symposia was a presentation by one of our colleagues from the AMPP MLDP, a PHD student from Texas A&M University.

Tuesday evening was kicked off with a BP sponsored drinks reception, followed by the headlined EMERG Scholarship Awards Ceremony and Emerging Leaders Bash where we were presented with our certificates for the YEP programme. Wednesday was mainly focused on attendance of symposia on “Corrosion Protection in Offshore Wind” a topic that is new to myself but attendance provided great insight and learnings on the subject. This day also included the attendance to the Exhibition, sadly not making the putt for the chance to win a Scotty Cameron putter but was able to visit stands of a few of my company’s NDT equipment and condition monitoring suppliers for equipment demos. As part of the exhibition we also had the opportunity to get a walkthrough of paint inspection methods and equipment, and also visit the AMPP Student Poster presentations where a few of our colleagues from the MLDP were presenting.

On Thursday, the final day of the conference proceedings, symposia attended consisted of “Hydrotesting, Mothballing and Preservation” including failure investigations on stagnant lines and conclusion of presence of MIC, “Aboveground Storage Tank Bottom Cathodic Protection” including presentation on the findings of an off-line inspection and corrosion identification of a water storage tank and “Machine Learning for Corrosion Management” including overview of Ultrasonic Guided Wave techniques utilisation for machine learning for corrosion monitoring in Pipes. As part of the package for attending the Conference we also have access to the recorded sessions on-demand to revisit attended sessions or catch-up on sessions that we wished to attend but clashed with schedules at the time – so the takeaways from the conference are still very much ongoing, which is a huge benefit to my continued professional development. Through the exposure to a wide range of asset integrity innovations and in-development solutions, it has sparked a real interest to better understand these technologies and diversify my knowledge in subjects such as corrosion monitoring solutions and cathodic protection.

Conclusions

Overall, from the outset of the programme itself and the opportunities created following, the Young Engineer Programme has given so much exposure to field of corrosion, asset integrity and related topics. This has been such an invaluable experience, opening doors and my mind to further progression in my professional life.

Each aspect of this journey has afforded many networking opportunities to better integrate me as an individual in the asset integrity industry and develop professional relationships and rapports with subject matter experts in the fields of asset integrity.

I would like to thank ICorr, especially Yunnan Gao (ICorr’s Vice President), a former colleague at STORK and now with BP, for introducing me to the programme in the first place and would encourage any prospective candidates of the YEP programme to go for it and take hold of all the opportunities that are available from it.

ICorr Microbiologically-Influenced Corrosion (MIC) Courses

The next ICorr MIC course is scheduled for October at the headquarters in Northampton. MIC is one of the least understood corrosion phenomena, despite being responsible for a number of high-profile failures. The Aliso Canyon gas leak in 2015 was caused by external MIC rupturing a storage well and the civil lawsuits were settled for US$ 1.8 billion on 27/9/2021[1], on top of utility fines and the cost of repair and containment.

MIC phenomena affect all systems with even traces of water in most industries. Different microbial groups have been identified and are affecting most construction materials.

The ICorr course is the only MIC training programme that is certified by a recognised professional organisation.

Dates:

The awareness course is scheduled for 4/10/2024

The certified MIC technologist course is scheduled for 23/10 to 27/10/2024

Venue:

ICorr headquarters, Northampton, UK

Registration:

Email: admin@icorr.org

Telephone: +44 (0) 1604 438 222

(1) SoCalGas agrees to $1.8-billion settlement in 2015 gas leak – Los Angeles Times (latimes.com)

Institute News

AMPP 2023 VISIT – DENVER

The 2022 YEP programme was chaired during the year by Hooman Takhtechian FICorr, and has been previously documented at: https://www.icorr.org/young-engineers-programme-yep-winners-night/ and see also (24) Post | LinkedIn

AMPP 2023 VISIT – DENVER

The five winning YEP delegates listed below all attended the 2023 AMPP exhibition, full conference, and leadership programme. The Institute of Corrosion is extremely grateful to AMPP, and to BP (our key sponsor) for making this all possible. Each of the YEP participants has produced a comprehensive journal, and these will be published in subsequent issues of the magazine (the first appears in this issue), as we move towards the start of the YEP 2024 programme.

YEP delegates at AMPP in 2023 were:

• Christopher Slater

• Eilidh MacDonald

• Jamie Hillier

• Lee Hunter

• Praveena Nanthakumaran, (who was on the winning team for the 2020 YEP competition but was unable to attend at that time)

Rosie Bird (from the 2022 winning team) was unfortunately not able to go to the AMPP event this year but it has been agreed that she will attend AMPP in 2025, alongside the 2024 winning team.

During October 2023, the winning students will make a presentation of their experiences to Aberdeen branch, and this will be available to all ICorr members, as a hybrid event to which AMPP and Young ICorr members will be invited.

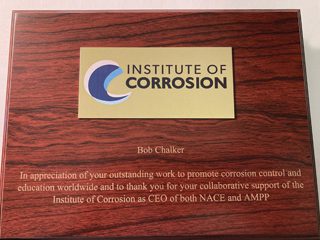

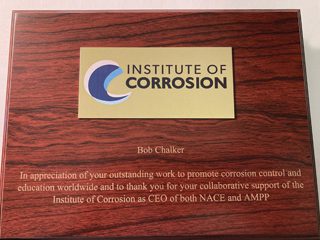

AMPP Retiring President

During the AMPP 23 event, a “thank you” plaque was presented to retiring AMPP CEO – Bob Chalker. Bob will be succeeded by Alan Thomas with a 2 month handover until July 2023.

The YEP wishes to express its gratitude to all the AMPP, BP and ICorr management teams, for their support and assistance provided for their 2023 visit, which was a huge success and greatly enjoyed by all. Some of the YEP winners’ comments are extracted here below, and their full journals will be published as space permits

YEP / AMPP – Delegate Feedback

• The YEP programme was a huge success. I developed my technical, communication, leadership, and teamwork skills, to a huge extent. I got to play so many different roles that I simply would not get exposure to during my usual day job as subsea engineer. At times I felt like a leader, a follower, a technical consultant, and a salesman. The value of the programme was really demonstrated to me through the opportunity to play these roles, (Jamie Hillier – Senior Subsea Engineer at Xodus Group, Aberdeen).

• If you are just starting your career as a young engineer and are interested in corrosion, I highly recommend applying for the ICorr’s YEP. It was an eye-opening experience. I have learned from SMEs in the industry, made fantastic friends along the way, and gained new and exciting opportunities through the programme. Additionally, the AMPP conference (and Leadership programme) winner’s prize, is incredibly valuable for knowledge transfer, networking, and potentially finding new clients or services for your company, (Praveena Nanthakumaran – Mechanical Engineering Graduate at Worley, London).

YEP – AMPP Visit prize – Leadership Programme / Conference / Exhibition / Awards

• On arrival at the event, we participated in a team building activity after being familiarised with the Drexler-Sibbet team performance model. This was a great way to get involved with other participants and build connections with them. The ‘carpet maze’ required us to work as a team to figure out the correct route to cross the mat without being able to talk to each other, in a limited time frame. This exercise was a practical way to teach us certain things that are directly applicable to the problems we face in a professional setting. Often, we just see our end goal, but to achieve this, mistakes will be made, side steps will need to be taken, and sometimes you even need to go backwards – it’s never just a straight route! (Eilidh MacDonald – Coatings Engineer at Subsea7, Aberdeen).

• The leadership programme experience left me feeling much more confident to go forward with my leadership and management skills, as I was able to develop effective communication skills. It gave me a good understanding of effective leadership, to make me feel much more confident going ahead as a leader to manage change. Also increasing my experience on how to navigate situations with heightened emotions effectively, being able to read a room and recognising what actions to take, through better emotional intelligence, depending on scenarios faced in professional and personal situations, (Christopher Slater – Project Engineer at STORK, Aberdeen).

AMPP 23 Conference – Participant Feedback

• I realised just how busy this conference was when I tried go to the Surface Preparation lectures – there wasn’t even standing room left! (Eilidh MacDonald – Coatings Engineer at Subsea7, Aberdeen).

• The AMPP seminars provided practical tips and strategies for overcoming challenges, and the opportunity to learn from industry experts was invaluable. I left the conference feeling inspired and motivated to apply the knowledge and insights I

had gained to my work, (Lee Hunter – Operations Manager at

AIM Group, Aberdeen).

AMPP 23 Exhibition – Participant Feedback

• Highlights of the exhibition for me were spending time discussing technologies on the market with various vendors. This included talking through pigging solutions to wax-filled pipelines, retrofit ICCP system solutions, and remote UT monitoring sensors. Being able to discuss these technologies and then bring back learnings from them into projects I’m working on would’ve been worth the trip to Denver alone, (Jamie Hillier – Senior Subsea Engineer at Xodus Group, Aberdeen).

• I was impressed by the diversity of the AMPP exhibitors and the range of products and services they offered. From coatings and corrosion protection solutions to equipment and instrumentation, the exhibitor hall had something for everyone, (Lee Hunter – Operations Manager at AIM Group, Aberdeen).

AMPP 23 Awards – Participant Feedback

• The EMERG Leaders Awards Ceremony at the Filmore in Denver, sponsored by BP was absolutely fantastic, and we were invited on stage to receive our ICorr YEP awards from Stephen Tate. It was also great to celebrate the achievement with the friends we had made on the MDLP earlier in the week, some of whom were also receiving awards that night. The atmosphere, the band, and the food (and drinks!) were great, and the night was definitely my highlight of the trip, (Eilidh MacDonald – Coatings Engineer at Subsea7, Aberdeen).

• The evening of entertainment and networking that followed the ceremony was a great opportunity to connect with like-minded professionals and learn from their experiences. Overall, it was a truly memorable event, and I feel privileged to have been a part of it, (Lee Hunter – Operations Manager at AIM Group, Aberdeen).

YEP 2024

We look forward, of course, to the next YEP competition, starting in January 2024, which will be managed by our very successful YICorr division, and take place in London. This 11-month programme provides a great opportunity for young engineers to expand their knowledge in corrosion management and engineering, and to combine it with their experience in energy and other industries.

The programme is designed to offer the following benefits:

1. Attendees will gain practical skills and knowledge on key issues in the energy industries, including Net-Zero technologies.

2. The lectures and workshops will form part of Continuing Professional Development (CPD) for the Institute of Corrosion. Additional attendance at local branch technical meetings will be encouraged where possible.

3. Attendees will develop teamwork and presentation skills from the workshops.

4. CPD points will contribute to participants’ progression to MICorr and Chartership.

5. Excellent opportunities for networking.

6. Increasing the skill level for engineers and decreasing the gap in knowledge between new and senior engineers, overall facilitating a better working environment within the sector.

All students will go through a series of evening lectures and be given a case study. Events will be held once a month from January to November (excluding August). Following is a list of the topics covered during the programme:

• Fundamentals of Corrosion • Cathodic Protection.

• Coatings & Linings

• Corrosion under Insulation/Fire Proofing

• Integrity Management / Fitness for Service

• Materials / Welding • NDT and Corrosion Monitoring

• Production Chemistry / Chemical Treatments

• Presentation Skills, (in the form of ‘How to solve a corrosion case study’ – This will cover the basics to presentation skills anecdotally but importantly teach the participants the keys to problem solving in the corrosion world)

James McGladdery will co-ordinate the next programme on behalf of YICorr, who can be contacted at:

James.McGladdery@uknnl.com, Tel: +44 (0)1946 556 600

Denver Conference Centre, Colorado.

YEP Winners, BP Sponsor and President at AMPP 2023 – (L to R),

Praveena Nanthakumaran, Eilidh MacDonald, Jamie Hillier, Timothy Bieri, Stephen Tate, Lee Hunter and Christopher Slater.

Presentation of the YEP Awards at the Filmore.

Plaque to Bob Chalker, retiring CEO of AMPP.