The cart is empty!

President Handover

Dear Members,

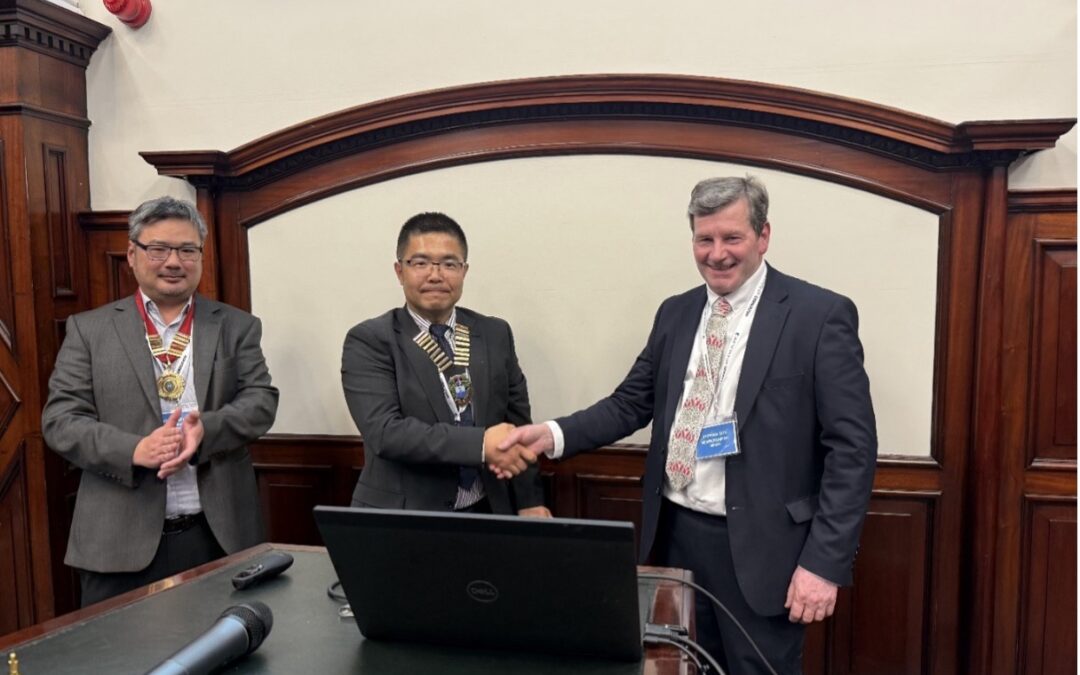

The Institute of Corrosion (ICorr) is very pleased to announce the successful election of Dr Yunnan Gao as its New President and Dr Anthony Setiadi as its New Vice President at its AGM held in Neville Hall, Newcastle on 13 November 2024.

Dr Yunnan Gao has been the Institutes’ Vice President and one of its Trustees since November 2022, in support of the immediate past president Stephen Tate on various ICorr matters over the past two years. Additionally, Yunnan has been an active ICorr Aberdeen branch committee member for the last 10 years when he has twice held the Chair position, helping to building up the Aberdeen branch from strength to strength. Yunnan has extensive working experience in energy sector both in the UK and overseas for 17 years.

Currently, Yunnan works for BP based in Sunbury, UK. After his PhD studies at Loughborough University, UK, he has worked for a number of energy and technical service companies including Atkins, DNV GL, LR, Repsol Sinopec, Saipem and Stork, in the areas of asset integrity and corrosion management. Yunnan is a UK Chartered Engineer (CEng), a UK Chartered Scientist (CSci), a fellow of ICorr (FICorr), a fellow of IOM3 (FIMMM) and an AMPP Certified Corrosion Specialist.

Photo. President Handover on 13/11/2024, Stephen Tate to Yunnan Gao at the ICorr AGM held at North-East Branch Newcastle, UK.

Photo. Our New ICorr Team, from Left to Right, ICorr New Vice President – Dr Anthony Setiadi, ICorr New President – Dr Yunnan Gao and ICorr New Immediate Past President – Stephen Tate

Dr Anthony Setiadi has been involved in ICorr for the past 13 years, whereby he was one of the organisers for the first ever Young Engineers Programme (YEP) and has supported this initiative through its successful iterations over the past 15 years. He has also been involved in the London branch committee as well as developing and supporting Chartership registrations to Engineering Council for ICorr.

Anthony received his PhD on materials from Sheffield University, UK, and is a Chartered Engineer (CEng) and Fellow of ICorr (FICorr), with experience in academia and industry covering various industries from nuclear, oil and gas and offshore wind. Currently, Anthony works as Chief Consultant for Wood Thilsted, a leading renewable energy consultancy, based in London, UK. His background and expertise are in materials and corrosion engineering for offshore and subsea environments.

We wish them both success in their new roles for the Institute and believe that together they will make a great partnership to lead the Institute from now on.

At this time, we would like to express our greatest gratitude towards our Immediate Past President – Stephen Tate, who recently retired from Oceaneering after 44 years in the Energy Sector. Stephen has led ICorr for the past two years where he has demonstrated excellent governance and leadership throughout and made a number of successes including recent involvement in setting up of the new ICorr UK branches in Southwest England & Wales and Central Scotland, as well as a renewal of the MoU with AMPP in the USA and sign off of the new MoU with CSCP (Chinese Society for Corrosion Protection) in China.

Stephen has set a very high bar for his successors to follow and with Stephen’s continued support as immediate past president and working together with the New ICorr President – Dr Yunnan Gao and New ICorr Vice President – Anthony Setiadi, the new team will endeavour to work wholeheartedly to continue the successes of ICorr and bring the utmost value and benefits to the ICorr corrosion community in the UK and overseas for the next two years and beyond.

ICorr Leadership Team’s contact details are as follows:

- ICorr New President – Dr Yunnan Gao: president@icorr.org

- ICorr New Immediate Past President – Stephen Tate: past.president@icorr.org

- ICorr New Vice President – Dr Anthony Setiadi: vice.president@icorr.org

Please feel free to contact us directly if you have any issues that you would like to discuss.

On behalf of the new ICorr Leadership Team, we thank you for your past support of the Institute and look forward to working with you over the next two years.

With our very best regards,

Yunnan, Stephen and Anthony