Institute News

ICorr, IMechE and TÜV Rheinland Mark 7 Years of Successful Partnership and Reach 1000th ICorr Approved Certifications in China

In a remarkable milestone, the Institute of Corrosion (ICorr), TÜV Rheinland (China) Ltd., and IMechE Argyll Ruane (Sheffield, UK) have celebrated seven years of fruitful collaboration. Since their partnership began in 2018, with the support of IMechE Argyll Ruane, TÜV Rheinland has historically offered more than 70 training courses, including Insulation, Fireproofing, Hot Dip Galvanising, and Protective Coating Inspector courses in China. This is now replaced by the New ICorr Passive Fire Protection (Epoxy) Coating Inspector training.

The 1000th certificate recipient, Mr. Huang Guangan, (ID No. 7163/C12287), who is the Coating Technical Director of Anhui Honglu Steel Construction (Group) Co. Ltd, based out of Hefei City, AH | Anhui, China and responsible for coating quality, training, coating process of the company, has demonstrated the local industry’s dedication to the quality assurance and recognition of ICorr scheme as international benchmark or personnel competence on surface treatment.

Anhui Honglu Steel Construction (Group) Company Limited manufactures and sells steel structures and related products. The company’s main products are equipment for steep structures, heavy steel construction, light steel construction structural products, and steel structure enclosure products. It has more than 20,000 employees and an annual production capacity of 6 million tons. At present, the group company has ten major production bases, with a total production plant area of more than 5 million square metres.

Mr. Stephen Tate, President of ICorr expressed his congratulations: “We are thrilled to reach this milestone. Our certificates provide confidence to project

owners, manufacturers,

and employers worldwide.”

Dr. Weikang Chen, Vice President of TÜV Rheinland Industrial Service and Cybersecurity extended his warm congratulations “As TÜV Rheinland continues its mission to enhance safety and sustainability, together with ICorr, it looks forward to certifying many more deserving personnel in the years ahead.”

TÜV Rheinland

Founded over 150 years ago, TÜV Rheinland stands as a global leader in testing services. With more than 20,870 employees and annual revenues of around 2.3 billion euros, they ensure safety and quality across various domains. Their commitment extends to virtually all areas of business and life, making them a trusted partner worldwide. On 20th June 2024, we had the pleasure of welcoming TÜV Rheinland (China) representative Anita Jing Fang to Northampton UK Headquarters of ICorr.

ICorr/IMechE Candidate Undertaking Level 2 Protective Coatings Inspector Course in China.

Huang Guangan – Protective Coating Inspector Level 2, Coating Technical Director of Anhui Honglu Steel and the 1000th ICorr IAR TUV Cert Holder.

Headquarters

of Honglu Steel

Construction

(Group) Co. Ltd.

Stephen Tate, President of ICorr with Anita Jing Fang, TÜV Rheinland (China) Ltd at the Northampton UK Headquarters of ICorr.

TÜV Rheinland Shanghai Office.

From Left to Right: ICorr Hon. Secretary Jane Lomas. Immediate Past President Bill Hedges, Anita Jing Fang, TÜV Rheinland (China) Ltd, President Stephen Tate and Vice President Yunnan Gao.

Source: Anita Jing Fang, TÜV Rheinland (China) Ltd.

Institute News

On Thursday 27th June 2024, Central Scotland Branch held its maiden event, this being an in-person presentation at: INEOS Grangemouth.

This opening event was well supported with over 20 attendees and was kindly sponsored by Carboline, who provided all the catering for the evening, and INEOS, who generously loaned their training centre for the event.

Lisa Anne Sweeney of Veolia Water Technologies and Solutions gave an excellent talk entitled “Cooling Water Treatment and its impact on Asset Integrity Management”.

The key theme of the presentation was understanding which corrosion mechanisms can be found in cooling water systems and what treatments can be applied to mitigate them. There was also an opportunity to explore a real-life example of a corrosion issue discovered within INEOS KG Cooling System and the approach taken to help resolve and mitigate this.

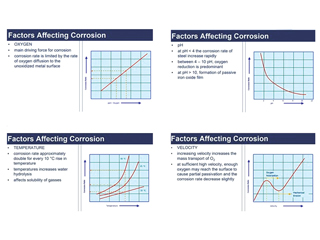

The key factors influencing corrosion and erosion were reviewed including:

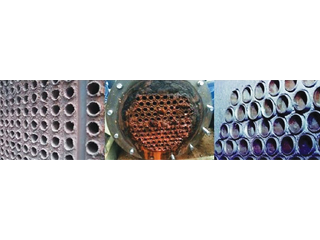

The enormous costs of corrosion and available mitigations were also reviewed. A heat exchanger case study was then examined from INEOS Plant.

It was determined that the primary cause of the heat exchanger damage in this case was microbiological corrosion caused by metabolic activity of microorganisms within the process:

- SRB

- Iron and manganese bacteria

- Slime formers – bacteria/fungi/algae

These types of microbiological life can excrete acids, which can lower the pH of the water, where corrosion is occurring and accelerate it. Historically, there had not been major issues prior to the recent plant outage and this discovery in 2019.

Subsequent Investigations, Monitoring

and Mitigations

All the following were performed:

- Deposit analysis performed.

- Review of cooling water analysis.

- Review of the chemical treatment plan.

- Re-started the bio-dispersant chemical on a trial basis.

-

Measured microbiological activity by using ATP method and off-site analysis.

This situation has now been rectified, but it has highlighted the enormous disruption that can be caused by MIC corrosion and the difficulties of removing contamination once initiated.

The Central Scotland Branch has formed an interim committee

for the 2024–2025 session under the distinguished chair of Philip Enegela. To make a presentation or to join the mailing list, please contact: philip.enegela@ineos.com

For the 2024-2025 Technical Programme, the normal event location will be: HQ Training Centre, INEOS Olefins and

Polymers, PO Box 21, 1 Inchyra Road, Grangemouth FK3 9XB

Photo 1: Attendees for the Launch Event of Central Scotland Branch.

Photo 2: Lisa Anne Sweeney of Veolia Water Technologies.

Photo 3: Veolia Advanced Water Treatment Solutions.

Photo 4: Veolia Heat Exchanger Case Study.

Photo 5: Heat Exchanger Fouling

Heat Exchanger Findings

Blogs, Institute News, Latest News

A Day to Connect, Learn, and Celebrate!

The Institute of Corrosion’s Annual General Meeting (AGM) is back, and this year we’re going in-person at the historic Neville Hall, Newcastle Upon Tyne. If you’ve been waiting for an opportunity to connect with your fellow ICorr professionals, engage with cutting-edge technical discussions, and enjoy a memorable evening of entertainment – this is it.

We’re also thrilled to announce that the evening dinner is sponsored by Correx and the ICATS team, who have generously supported this special event. Their commitment ensures an unforgettable experience for all attendees, from the fine dining to the vibrant atmosphere of the live jazz band.

Mark your calendars for 13th November 2024 and get ready for a day packed with exciting moments, insightful presentations, and great networking opportunities.

Whether you’re a seasoned ICorr member, a new face to the community, or a guest interested in the corrosion field, this is an event not to be missed!

Why Should You Attend?

To be opened by Mayor of Newcastle Rob Higgins, we’ve lined up an exceptional programme to cater to both the technical minds and the social butterflies among us:

· Offshore Wind Technical Program

Are you intrigued by the future of renewable energy? Our Offshore Wind Technical Program will explore the latest advancements in this thriving sector. Running from 2:15 – 4:00 p.m., this session is a great opportunity to learn, share insights, and discuss innovations that are transforming the offshore industry.

· Exclusive AGM Event

Starting at 4:30 p.m., the AGM is your chance to catch up on the latest developments within the Institute of Corrosion, hear from our President, and get a detailed look at the Council’s work. It’s the perfect forum for members to ask questions, provide feedback, and take part in shaping the future of ICorr.

· A Grand Evening Reception

And then… the evening begins! From 6:15 p.m., we’re hosting a drinks reception where you can enjoy a glass of bubbly while mingling with colleagues and friends. This leads into our elegant gala dinner, complete with a three-course meal and live jazz to set the perfect atmosphere. It’s a fantastic opportunity to relax, unwind, and celebrate another successful year for ICorr.

Priority seating for the dinner will be given to ICorr professional members and sustaining organisations, so don’t wait too long to register!

Register Your Attendance – It’s FREE!

The best part? The event is completely free of charge, including lunch, refreshments, and all activities throughout the day. Just one more reason to make sure you’re there! However, spaces are limited, and we encourage you to register early to secure your spot.

Here’s how:

To confirm your attendance (or send your apologies), simply email nechair@icorr.org and don’t forget to include:

- Your ICorr membership number

- Professional grade

- Sustaining member organisation (if applicable)

- Or let us know if you’re attending as a guest.

Event Details at a Glance:

Date: 13th November 2024

Location: Neville Hall, Westgate Road, Newcastle Upon Tyne, NE1 1SE

Running Order:

- Lunch and Registration: 1:00 p.m.

- Offshore Wind Technical Program: 2:15 – 4:00 p.m.

- AGM: 4:30 – 5:15 p.m.

- Drinks Reception & Gala Dinner: 6:15 p.m. – late

Venue: The Library, Neville Hall

This day promises to be filled with valuable knowledge-sharing, meaningful connections, and great fun. We can’t wait to see you there.

For further details, feel free to contact us at admin@icorr.org or check out our social media channels for the latest updates.

Let’s Make 2024 a Year to Remember!

Don’t miss out – register now and be a part of this incredible day! We look forward to welcoming you in Newcastle for an event that’s sure to inspire, educate, and entertain.

Institute News

ICorr Welcomes New Sustaining Member – Automa

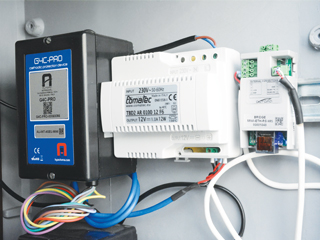

Founded in 1987, AUTOMA is an Italian company specialised in the production of solutions for the remote monitoring and control in the oil, gas, and water sectors. The company is best known for the design, engineering, and production of advanced solutions that enhance the efficiency and safety of distribution and transportation networks.

AUTOMA has introduced solutions for the remote monitoring and control of cathodic protection systems of buried metal structures in the water, gas, and oil industries, with over 45,000 units worldwide. Its cathodic protection suite offers reliable solutions for monitoring, logging and functional control of activities thanks to a variety of devices that can be used both remotely and locally.

AUTOMA has also developed a proprietary SCADA system specifically designed for the cathodic protection field, that allows users to carry out analysis of historical data and graphs, to configure all the devices, to download reports and to receive real-time alarms.

The complete solution, known as GOLIAH®, offers all the necessary tools for a correct and timely monitoring in accordance with the current industry standards. This guarantees network operators real and complete ownership of all data and enabling a real-time and accurate control of the cathodic protection system. www.goliah.info/en/

AUTOMA’s key focus is on the quality and reliability of its products, guaranteed by international certifications and a constant commitment to innovation. Each solution is custom-designed to meet customer needs, supported by a dedicated research and development team.

Contact Information

AUTOMA s.r.l. Ancona (An) – Italy

Tel.: +39.071.8028042

e-mail: sales@byautoma.com

www.byautoma.com

Automa G4C-Pro CP Monitoring Device.

Automa Intermediate CP Monitoring Station.

Institute News

ICorr Welcomes Corrodere Academy: Pioneering Excellence in Corrosion Control Training

Introduction

The Corrodere Academy stands as a beacon of expertise in the field of corrosion control alongside ICorr, providing unparalleled education and training to professionals worldwide. With a mission to combat the pervasive challenge of corrosion, the Academy equips individuals and organisations with the knowledge and skills necessary to protect assets, ensure safety, and enhance durability across industries.

History and Evolution

Founded in 2000, the Corrodere Academy began with a vision to address the growing need for specialised corrosion control and prevention training. Over the years, it has evolved into a globally recognised academy, offering a comprehensive suite of courses and certifications tailored to meet the diverse needs of industries such as oil and gas, marine, construction, manufacturing and renewables.

Course Offerings

The Academy’s portfolio of courses has been designed to cover all aspects of corrosion control including inspection, application and specialist knowledge.

- Inspection

– ICorr endorsed Coating Inspection Level 1, 2 and 3 courses.

–

Other introductory Coating Inspection courses covering Insulation, Fireproofing, Pipeline, Hot Dip Galvanising,

Thermal Metal Spraying, and Marine Coatings.

- Train the Painter

–

Protective Coating Application, Spray Painting and Abrasive Blast Cleaning modules.

- Specialist Coating

–

Corrodere Diploma in Coatings for Corrosion Control

alongside Coating Surveys, Corrosion Management and Corrosion Under Insulation courses.

Each course combines theoretical knowledge with practical, hands-on training, ensuring that participants gain a deep and actionable understanding of their chosen subject.

Certification Programmes

The Corrodere Academy offers internationally recognised QCA certification that validates the skills and expertise of industrial

coating applicators. Certifications such as are highly regarded in the industry, often serving as a benchmark for excellence.

– QCA – A1 Abrasive Blast Cleaner

– QCA – P1 Protective Coatings Applicator

– QCA – S1 Spray Painter

– QCA – T1 Thin Film Intumescent Applicator

Expert Faculty

The Academy’s strength lies in its team of seasoned experts, who bring a wealth of experience and knowledge to the training material. These industry veterans are not only educators but also active practitioners, providing students with insights drawn from real-world challenges and solutions.

Global Reach

With a network of training centres and partners around the world, the Corrodere Academy extends its reach globally, providing its training material in multiple languages, that makes its portfolio of courses accessible to a diverse audience. This international presence ensures that the Academy stays at the forefront of global trends and developments.

Industry Collaboration

Collaboration with industry leaders and professional bodies such as the Institute of Corrosion is a cornerstone of the Corrodere Academy’s approach. By partnering with key stakeholders, the Academy ensures its training programmes are aligned with industry standards and address current challenges within the corrosion prevention industry. These collaborations also facilitate development initiatives, driving innovation in corrosion prevention and control.

Success Stories

The impact of the Corrodere Academy is best illustrated through the success stories of its alumni. Students have gone on to make significant contributions in their respective fields, from ensuring safety is at the highest level on site, to progressing their careers and leading large-scale corrosion management projects.

Future Initiatives

Looking ahead, the Corrodere Academy is committed to continuing its tradition of excellence and innovation in training delivery. Future initiatives include:

-

Development: investing in market research to stay ahead of emerging corrosion challenges and provide training solutions to industry.

-

Expansion of Online Training: Enhancing the accessibility and flexibility of its programmes through advanced interactive e-learning platforms.

-

Sustainability Focus: Integrating sustainability into its training programs, emphasising eco-friendly corrosion prevention methods, and company operational initiatives.

Conclusion

The Corrodere Academy stands at the forefront of corrosion control education, closely working with international corrosion societies and setting the standard for excellence in the field. By offering cutting-edge training, fostering industry collaboration, and driving innovation, the Academy plays a pivotal role in protecting assets and ensuring safety across industries worldwide.

Contact Information

For more information, visit the Corrodere Academy website or contact the team directly to learn how they can help your organisation.

www.corrodere.com

T: +44 (0) 1252 732 236

E: Lucy Pavia lucy@corrodere.com

Powder Coatings Course.

Blast Cleaning Course.

ICorr Level 2 Coating Inspector.

Institute News

On Monday 30th September 2024 John Fletcher (ICorr past president 2014-2016) will stand down as the ICorr Surface Treatment Training Scheme Manager (STSM) and hand over this role to Dr Jane Lomas, who has been the Deputy since the role was formalised in 2019.

John’s direct involvement with the ICorr Coating Inspector training schemes started when he joined the ICorr Professional Development Training and Certification (PDTC) committee in 2007, when the scheme was managed by David Griffiths. However, the informal involvement predates 2007 when he was working at Elcometer as Technical Support Manager and had regular contact with Argyll and Ruanne who delivered the courses in Rotherham, particularly regarding new coating inspection instrumentation and tests. He joined Elcometer in April 1982, and was soon asked by President Bill Cox to join the ICorr North-West Branch to represent Elcometer as the owner of the company was busy travelling the world to develop the export market. This involvement ultimately led to him joining PDTC and to become President of ICorr.

Prior to joining Elcometer, John worked for 13 years at Philips where he was responsible for developing and implementing metal coating processes for both semiconductors and insulators for the development and manufacture of microwave components for radar systems. At the time, John did not realise that this coating related work would lead to an extensive involvement later with ICorr.

John’s technical role at Elcometer involved BSI and ISO standards work and through his informal support of the Elcometer membership of ASTM. He became a regular attendee of ASTM D01 meetings becoming Chair of D01 and finally a Director of ASTM for a three-year term which ended in 2019 and resulted in an award of lifetime excellence from the ASTM D01 committee

in 2019.

John remains incredibly grateful for the tremendous support provided by his employer, Elcometer, for the work entailed in managing the ICorr Surface Treatment Training Schemes up to his retirement from Elcometer in December 2019, and it is his belief that they saw the long-term benefit of his relationship with ICorr to Elcometer’s core business. The STSM function is, of course, critical to the delivery of quality ICorr training courses with many sub-duties. In preparation for his Elcometer retirement, John agreed to a contract with ICorr to continue to manage the Surface Treatment Training Scheme on a one-day per week basis.

Earlier in 2010 John had become the Chair of PDTC and the involvement with Argyll Ruane grew, with David Griffiths and later with Nigel Peterson-White and Richard Green, who all delivered the classroom courses. Also in 2010, ICorr signed its first agreement with Corrodere to deliver online Coating Inspector courses. At the time John had expected that all ICorr Coating Inspector courses would be delivered online thereafter but that has proved not to be the case as there are still a substantial number of students who prefer the classroom environment, despite the additional accommodation and travel costs.

In 2013 the Argyll Ruane operation was sold to the Institute of Mechanical Engineers who are based in London. It is true to say that they were primarily interested in the NDT/NDE training courses offered by ARL and backed by BiNDT, but IMechE was soon keen to create a new agreement between IMechE A R (IAR) and ICorr. Under John’s leadership, the activity at IAR in Sheffield has developed significantly since the days when ICorr courses were delivered in temporary buildings on the outskirts of Rotherham. They now have a’state of the art’ training centre developed from a former call-centre building with rooms dedicated to ICorr course delivery and ICorr examinations.

IAR now offers ICorr courses through their regional partners in various countries, including China, where TUV just celebrated their 7th year offering ICorr courses and their 1,000 certificate just issued via the ICorr scheme.

For their part, Corrodere has extended the courses they can deliver online to include the Level 2 course for Insulation, Pipeline and Hot Dip Galvanising Inspectors and approximately 50% of the applications for ICorr certificate come from candidates who are based overseas.

In conclusion, John would like to express his sincere gratitude to both IAR and Corrodere for their continued support in developing and increasing the numbers of Coating Inspectors who are trained and certified by ICorr.

John will remain on ICorr’s Council in 2025, if elected at the AGM later this year and will be available to support Jane in her new role as Surface Treatment Training Scheme Manager whenever required. The Institute wishes to express its sincere thanks to John for more than 40 years’ invaluable service to the Institute in various ways and we all wish him good health and happiness in his pending retirement.

John Fletcher – STSM Scheme Manager.