Uncategorized

GPT Industries (Wheat Ridge, CO), a provider of Cathodic Protection solutions for over 35 years, has announced the launch of its remote pipeline monitoring system, Iso-Smart™. With nearly four decades focused on corrosion prevention, GPT is leveraging extensive industry expertise to set a new standard for a versatile, user-friendly remote asset integrity monitoring.

Iso-Smart is an all-in-one solution developed based on customer feedback for checking Cathodic Protection (on and instant off potentials), Isolation, Bond currents, AC vs. DC on the line, and more from remote locations. It incorporates True RMS technology to provide reliable data, helping pipeline owners make informed decisions and comply with DOT pipeline integrity regulations.

The Iso-Smart solution seeks to combine corrosion expertise with the latest remote monitoring technology.

Key features of Iso-Smart enabling this remote monitoring capability include:

- An intuitive dashboard

- Cellular LTE connectivity

- Rechargeable battery for

multi-year operation

- Rugged, compact design

Iso-Smart was recently showcased at the 2024 Association for Materials Protection and Performance (AMPP) Conference. Interested parties can request a demonstration or find more information by visiting www.gptindustries.com/products/iso-smart

Institute News, Uncategorized

World Corrosion Awareness Day’ a University of Manchester / ICorr NW Joint Event

To celebrate World Corrosion Awareness Day, the Institute

of Corrosion Northwest Branch held a joint event with the University of Manchester (UoM) on 24th April 2024.

The event comprised an afternoon of exciting and varied presentations from University of Manchester and

industry speakers:

The Role of Organophosphates in Corrosion Inhibition,

K Brook (University of Manchester)

With a background in the coatings industry, Kathy presented post-graduate research on this innovative area of corrosion prevention.

Cathodic Protection of Wind Turbine Monopiles – Internal and External Issues, David Buxton (Intertek CAPCIS)

David Buxton is a Corrosion Consultant who has spent over 30 years working in cathodic protection and stray current corrosion control. David completed a PhD at the Corrosion Centre (UMIST/University of Manchester) and has been at Intertek CAPCIS for 20+ years undertaking both onshore and offshore cathodic protection related investigations, testing and assessments. He outlined key issues associated with cathodic protection in the emerging area of renewable energy.

Quff: An Innovation in Quantum Computer Programming, Christopher Wright (University of Manchester)

Christopher presented on this new programming language, developed for the fast-moving field of quantum software engineering. Quff is a high-level, dynamically typed

programming language focused on simple yet effective hybrid programme development.

My Corrosion Journey: Dr Jane Lomas

(ICorr / Amtec Consultants Limited)

The talk covered many aspects of the working life of a corrosion engineer and the role that ICorr has played in Jane’s corrosion journey. Whilst obtaining a BSc in Biochemistry, an interest in the problems with corrosion of metal hip joint replacements made an MSc in Corrosion seem a logical next step. This led on to the establishment of an independent corrosion consultancy and jobs ranging from beer

cans to aeroplanes; bulk carriers to battleships; building and factory corrosion issues to corrosion of classic cars, church windows and on the leisure front even Blackpool Tower.

Safety Risks Cannot Be Overstated: The structural integrity

of buildings, bridges, and transportation can be severely compromised by corrosion and have led to many catastrophic failures. https://www.bbc.co.uk/news/uk-england-34335931 and http://news.bbc.co.uk/1/hi/scotland/glasgow_and_west/8495807.stm

The “World Corrosion Organisation (WCO) has previously designated 24th April as “World Corrosion Awareness Day”. This day aims to encourage the adoption of corrosion prevention strategies to reduce the economic and social costs associated with corrosion. The World Corrosion Awareness Day reminds the world that ‘rust never sleeps’ and recognises the impact corrosion prevention and control professionals make. It promotes sustainable management practices for critical industrial assets like energy infrastructure, transportation infrastructure, water/wastewater and waterways, the shipping industry, defence assets, and more.

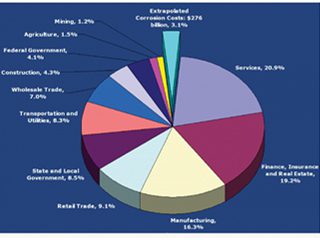

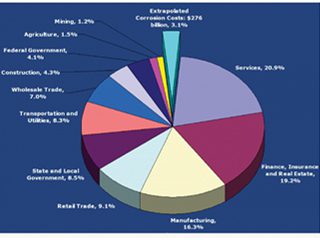

The estimated annual cost of corrosion, amounts to US$2.5 trillion globally and accounts for 3 to 4% of the GDP of developed nations, according to earlier research by AMPP, a global non-profit organisation that represents more than 32,000 members in the materials, corrosion control, and coatings industries. and brought to light on World Corrosion Awareness Day. This figure may be attributed, in part, to the lack of understanding among government and industry decision-makers regarding the seriousness of corrosion and the need for control.

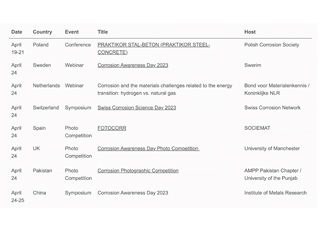

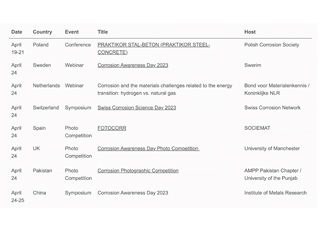

Every year on World Corrosion Awareness Day, seminars, conferences, webinars, competitions, and student events are organised by corrosion associations worldwide to raise public awareness of corrosion and corrosion control among decision-makers in government, business, and academia.

Some of the events conducted on corrosion awareness day 2023 are listed below. An elaborated list of events conducted on corrosion awareness day for previous years is available on

the World Corrosion Organisation (WCO) Website

(https://corrosion.org)

It is estimated that the use of corrosion control techniques will reduce the annual cost of corrosion worldwide by 15 to 35 percent, or $375 to $875 billion. The other intangible advantages to public safety and the environment that come with long-term, consistent asset integrity also add up to these substantial cost savings. Corrosion control specialists are in charge of averting catastrophic failures that can endanger public safety, cause lost output, deteriorate the environment, or result in fatalities.

You may like to read our Corrosion Awareness Day article published on the ICorr website:

www.icorr.org/world-corrosion-awareness-day-family/

Source

www.ampp.org

www.corrosion.org

www.icorr.org

Further Reading

Note: On 1st July 2024, an ICorr Sponsored – Parliamentary and Scientific Committee Event will take place with several Institute speakers including: Professor Gareth Hinds, Dr. Christian Stone and Izabela Gajewska.

Full details will be announced during April 2024. Some recent everyday examples of corrosion impacts to Infrastructure may

be found at:

Coast Road barrier corrosion speed limit to remain – BBC News

‘Severe corrosion’ found during Cleveland Bridge repairs – BBC News https://www.bbc.co.uk/news/uk-england-58494275

Above: An Example of Complex Infrastructure Requiring Special Anti-Corrosion Measures.

Extrapolated Corrosion Costs – Source: www.ampp.org

Above: Events Conducted by Various Corrosion Associations in 2023 on Corrosion Awareness Day.