The cart is empty!

The Institute of Corrosion is very pleased to welcome its latest Corporate Member – Flexitallic, a leading player in the prevention of Flange Face Corrosion.

As part of the global Flexitallic Group, the West Yorkshire-headquartered company has a network of UK branches in industry-focused locations such as Aberdeen, Teesside and Merseyside. The branches act as the distribution arm for the Flexitallic portfolio of specialised sealing products including its range of gaskets designed and manufactured to meet the requirements and safety-focused operations of sectors including oil and gas, power generation and petrochemical. Flexitallic has created dedicated gasket cutting and winding facilities to provide customers with a more responsive and efficient same-day service. Flexitallic Group is an international market leader of high-quality, high-value industrial static sealing products, including industrial gaskets. The company’s sealing solutions and products support operations in the oil and gas, power generation, chemical and petrochemical industries in emerging and developed markets. Focused on the upstream, downstream and power generation sectors, Flexitallic has operations in the United States, Canada, Mexico, the United Kingdom, France, Belgium, Germany, Italy, the United Arab Emirates, Thailand, and China plus a network of worldwide licensing partners and distributors.

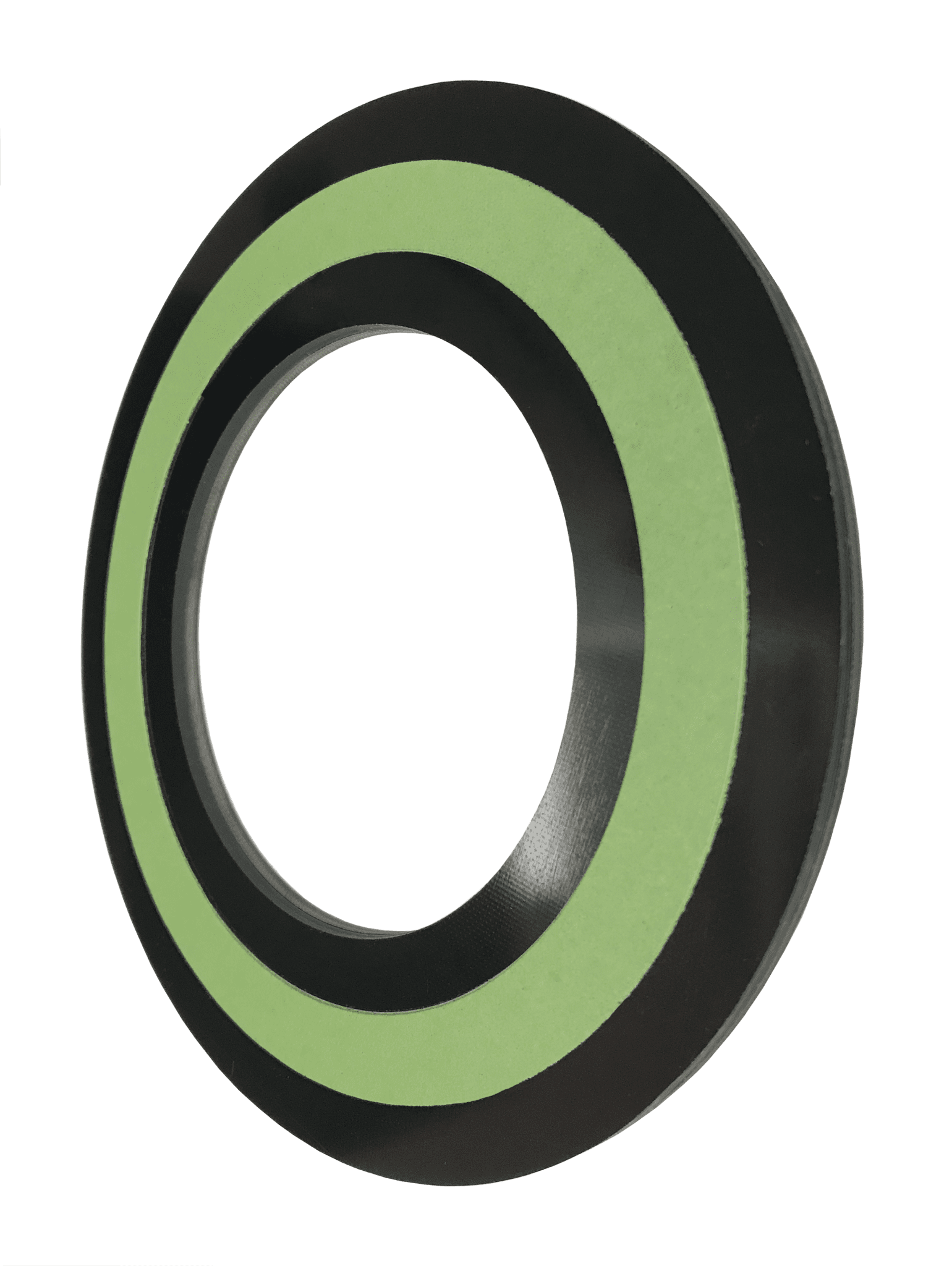

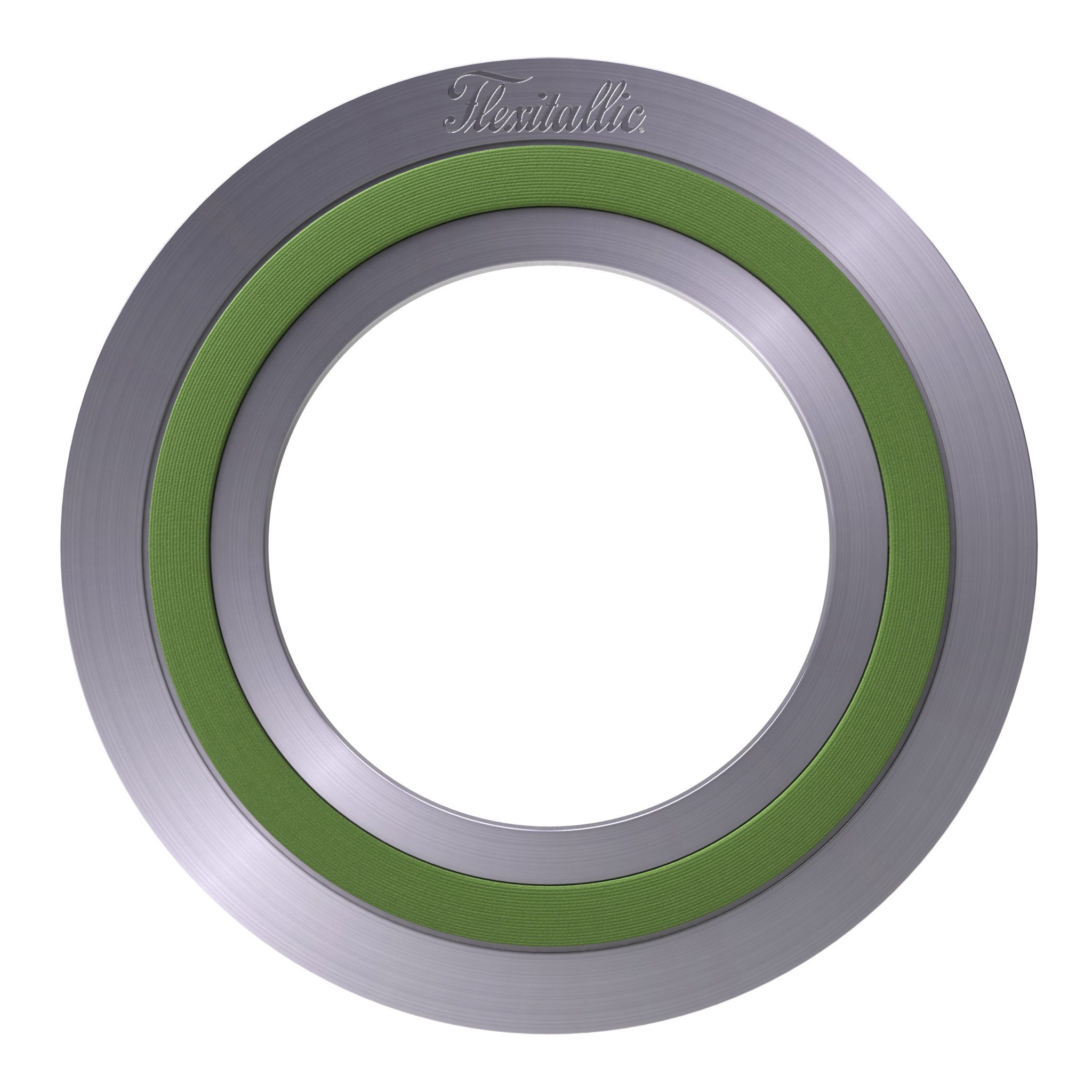

Over the decades, Flexitallic has built on its legacy of innovation, starting with the Spiral Wound Gasket in 1912 and continuing with new corrosion prevention products and materials such as: Corriculite®, The Flange Rescue Gasket® and ISO-Flex™ Isolation Kits for Piping systems.

By drawing upon their rich history and present-day values of safety, quality, continuous improvement, teamwork, integrity and performance, Flexitallic remains at the forefront of developing sealing solutions for industries around the world.

Flexitallic believes it has a responsibility to support its customers to help achieve leak free start up and operation within the scheduled maintenance cycle, allowing customers to operate their plants, complete projects and start up from turnarounds safely and efficiently. Through a team of Applications Engineers that specialise in bolted joint integrity, they are dedicated to supporting end-users when faced with problematic sealing applications. Services offered range from the provision of torque and tension information for standard connections, through to creating comprehensive design reviews for bespoke connections on critical equipment.

To complement their joint integrity services, through its Academy of Joint Integrity, Home – The Academy Of Joint Integrity the company delivers an accredited and comprehensive flange assembly, sealing technology and critical bolting training programmes for all industry sectors. The academy provides IChemE and ECITB-accredited, bespoke and practical training to engineers and technicians, covering all areas of joint integrity. Programmes are designed to increase competencies, reinforce Flexitallic’s commitment to safety and improve industry-wide standards.

Flexitallic UK Cleckheaton

Flexitallic Aberdeen Base

FLEXITALLIC Corriculite Flange Face Protection Gasket

FLEXITALLIC Flange Rescue Gasket

FLEXITALLIC ISOFLEX Isolation Gasket