Uncategorized

The second of the series of YEP-AMPP Journals, by Eilidh Macdonald, 2022 YEP Winner.

“ICorr’’s YEP was a fantastic programme to be a part of, with the unforgettable experience of attending the AMPP Annual Conference in Denver, Colorado. I’d highly recommend this programme to any young professionals who are interested in joining the corrosion industry”.

Here is my personal

AMPP diary.

Saturday 18th March 2023

Our trip truly commenced on Saturday, after recovering from the jet lag of the ~12 hour journey to Denver, Colorado. We attended the first (and only in-person) session of the AMPP Members Leadership Development Programme (MLDP). The five of us representing ICorr were joined by nine other participants hailing from various states in the US. The entire day was incredibly useful, with engaging and insightful sessions throughout the day.

In the morning, we were introduced to various members of the AMPP Board of Directors, which showed how interested they are in the next generation of engineers in the industry, just as ICorr is. We covered a variety of topics and gained a more in-depth view of the AMPP business model and strategic plans with Kim Ray and Lauren Blachman. We also participated in a team building activity after becoming familiar with the Drexler-Sibbet team performance model. This was a great way to get involved with other participants and build connections with them. The ‘carpet maze’ required us to work as a team to figure out the correct route to cross the mat without being able to talk to each other within a limited time frame. This exercise was a practical way to teach us certain things that are directly applicable to the problems we face in a professional setting. Often, we just see our end goal, but to achieve it, mistakes will be made, side steps will need to be taken, and sometimes you even need to go backwards—it’s never just a straight route.

In the afternoon, Phil Reynolds took us through a captivating session on Emotional intelligence, and it was interesting to become aware of our personal areas of development and be given meaningful advice on how to improve them. During this introduction session, we were also assigned groups, either relating to ‘Workforce’, ‘Knowledge’ or ‘Advocacy’ which we will continue also received an invitation to the Board of Director’s Opening Reception.

After being at the first session of the AMPP MLDP that day, it was great to be able to recognise some of the faces we had seen throughout the day and get to know the other participants of the programme better.

Sunday 19th March 2023

On Sunday, the conference officially started at the Colorado Convention Centre. The exhibition hall was still being set up and had not been opened at this point. However, there were plenty of presentations and discussions to attend throughout the day.

The day seemed to continue around the theme of coatings for me, which was ideal. The other main presentation I attended this day was focused on Maintenance painting/repairs. It was interesting as it was based on issues faced by the American Department of Defence, which is quite different from the work I do for Subsea 7 in coating systems. It also covered the maintenance and repair of structures in onshore corrosive environments, such as bridges, and it was very good to learn about the typical maintenance programme structure followed in the industry and also the issue of overcoating with incompatible materials. The seminar also briefly covered a small section on 1-coat systems, which I found interesting as I haven’t had any involvement with these before

I soon realised just how busy this conference was when I went to try and go to the surface preparation lectures—there wasn’t even standing room left. Although it meant I missed out on learning more about this topic, I headed to the presentations given on internal corrosion to learn more about this area instead. There was a presentation on the Investigation of Spring Failures in the North Sea. I found it interesting to have a practical case, and throughout the conference I was much more interested in the ‘real-life’ cases compared to the theoretical paper studies that were presented. Although these were also very insightful, the studies based on real scenarios seemed more aligned and applicable to the work I perform.

After a full day of lectures and presentations, we headed along to the opening ceremony of the event, which was sponsored by Carboline. Again, I couldn’t get over the number of people who were attending the conference. It felt great to be surrounded by so many others who are passionate and like-minded about corrosion. Once the opening reception was finished, we went for dinner, and, I think, for all of us, it was our first-time trying Denver style deep-dish pizza. Truly phenomenal – the Americans do it so well.

Monday 20th March 2023

Having found my bearings around the Colorado Convention Centre on Sunday, and now understanding better the format of the lectures the previous day, I was able to take full advantage of what was on offer. I attended various presentations, including Premature Coating Failures, which went through real case studies, and the presenter encouraged the audience to provide their thoughts before going through what had happened. It was very engaging and also covered common failures in different materials and environments. I found the failures in concrete to be interesting, as this is a material that I’ve not had much experience with yet in my career.

The next presentation I attended was ‘Coatings Failures investigations – Finding the Cause. This also went through case studies, but with a different view than the last. It also focused on the importance of ensuring the specifications are always followed correctly, and the responsibilities of the different parties in the scenarios, such as the manufacturers, suppliers, applicators, contractors, and clients.

Later, I attended a presentation on ‘Materials Selection and Cost Control’. It was based on the comparison of several bridges and their associated CAPEX and OPEX costs. It highlighted the superiority of duplex coating systems, even though they had considerably higher CAPEX costs, the maintenance was much lower, resulting in them actually being far cheaper and lasting three times longer than paint systems. Another lecture I attended on Monday was on ‘Internal ICCP of Offshore Wind Monopile Foundations’. I’ve only had a little experience with offshore wind structures, focusing on sacrificial anodes, so it was interesting to learn more about the application of ICCP in this industry. The presenter went through different systems and case studies. It was interesting to understand the evolution of the system in this industry, where closed systems were originally used, Open systems are generally more preferred to allow free flow of water to the internal sections, using current trends to maximise the placement of ‘refreshment’ holes.

In the evening, we attended the AMPP Exhibition Grand Opening. There were 376 exhibitors covering all aspects of the corrosion industry, It was truly amazing to see the enormity and scale of the exhibition and what it had to offer.

After the official Exhibition opening, we went for a lovely dinner with various other senior members of ICorr who had also made the long trip to Denver for the conference. It was great to meet familiar faces that I had only seen before through Virtual Meetings and have a good chat about all things corrosion and otherwise.

Tuesday 21st March 2023

On Tuesday I again set out to attend lectures on different subject matters. My first presentation of the day was, ‘Innovative Approaches for Mitigation and Monitoring of Microbial Induced Corrosion in Seawater’. This highlighted the findings of a technical paper and I found it insightful to learn more about the upcoming and novel approaches being used for this prevalent issue.

I also attended a lecture given on the ‘Alternative CRA Materials for Line Pipe application’. I found it interesting as the speaker discussed challenging the CRA thicknesses provided in standards and doing further testing to make this value less conservative to reduce CRA material, as well as mentioning different CRA materials from the typically seen nickel-based alloys.

Subsequently l attended a presentation on ‘Predicting the enhanced effects of coating deterioration in marine environments’. Again, this was based on a technical paper which was much different to the lectures I had attended in the previous days. It was interesting to see the work being done to try and fully understand certain phenomena witnessed from organic coatings systems. The presenter explained the test result data of the deterioration in detail and highlighted the next steps they would take in experiments.

Later I went to a lecture on ‘The Myths of Insulation Treatments and CUI – What Works and What Doesn’t’. I was very keen to attend this one as my Masters dissertation was based on CUI, and the presentation even had a section on the same test method I had studied. It discussed and compared different insulation systems and their associated pros and cons when it came to CUI, and the importance of corrosion prevention being treated as a complete system approach of the cladding, insulation material and coating. After a full day at the conference it was time to get ready for the EMERG Leaders Awards Ceremony at the Filmore in Denver, sponsored by BP. The night was absolutely fantastic and we were invited on stage to receive our ICorr YEP awards from Stephen. It was also great to celebrate the achievement with the friends we had made on the MDLP earlier in the week, some of whom were also receiving awards that night. The atmosphere, the band, the food (and drinks!) were great. The night was definitely my highlight of the trip.

Wednesday 22nd March 2023

I spent the majority of my Wednesday going around the Exhibition Hall and talking to lots of different stalls. There were many large companies and it was great to talk to their representatives about upcoming technologies and processes. It was an ideal opportunity to ask questions directly and gain the right contacts for questions that may arise in the future. The exhibition hall also had a practical section to show coatings and CP testing and monitoring systems which was great to learn more about by getting to use it and understand it better.

Several people we had met at the MLDP were presenting their posters at the Student Poster Session, so it was great to talk to them in more detail about their specialised areas and thesis projects.

The work they had all put into their posters was extraordinary, and it was good to see so many other young people so interested in the corrosion industry. Unfortunately, none of us were lucky enough to win the Harley Davidson that was up for grabs! In the evening, we met with a few friends made over the course of the week for some final goodbyes over bowling and arcade games.

Thursday 23rd March 2023

Thursday was sadly my final day in Denver, as I was leaving in the afternoon. Denver had an electric feeling to it. AMPP 23 was a truly unforgettable experience with so many amazing memories made with fantastic people.

In the Thursday morning I still had a little time left to cram in a couple of presentations including ‘Susceptibility of martensitic steels to hydrogen embrittlement’. This isn’t an area I was as familiar with but it was interesting to learn which material properties increase the risk of hydrogen embrittlement and why this is the case. Following on from this I attended a presentation called ‘It’s Stainless Steel, we don’t

need to worry…right?’ It was interesting to learn of case studies which magnified the point that management plans need to be implemented regardless.

After the morning sessions, it was time for me to say my goodbyes with the rest of the YEP team over some lunch before I headed to the airport. It was great to meet everyone and have such a valuable experience which has helped me to become a better engineer.

Thank you so much to ICorr and to BP for the opportunity to attend the AMPP Leadership course and Conference, I am incredibly grateful.

CAPTIONS:

Eilidh Macdonald – 2022 YEP Winner.

Blogs

The Future is Bright. The Future is Young ICorr It may be a cliché, but the successful future of the corrosion industry relies upon developing up-and-coming talent. Here at the Institute of Corrosion, we have a dedicated space to nurturing this talent – Young ICorr....

Institute News

The first of the series of YEP-AMPP Journals, by Christopher Slater, Project Engineer, STORK, Aberdeen, is given below.

The 2022 Young Engineer Programme (YEP) consisted of 9 evening lectures presented by specialists in their field, to provide technical competency and knowledge across the field of asset integrity to delegates, combining with the Aberdeen branch technical programme.

Subsea 7 loaned their training facility for this purpose. that were covered during the 2022 programme:

• Fundamentals of corrosion

• Cathodic protection

• Coatings and linings

• Corrosion under insulation / fire proofing

• Integrity management / fitness for service

• Materials / welding

• NDT and corrosion monitoring

• Production chemistry / chemical treatments

• Presentation skills

The case study presented a scenario whereby we were engaged by a mock integrity services contractor to advise an international company that is a newcomer to the operation of production facilities in the UK sector of the North Sea. This consisted of analysing the scenario and current integrity status of the pressurised systems on the mock platform through the evaluation of the provided data and performing an initial risk assessment to identify key threats to the mechanical integrity of the pressurised systems. The brief to develop our proposed application of a systematic methodology to manage corrosion and surveillance activities allowed for approaches to prolong service life, the use of innovative solutions, the assessment of material options for the new pipeline, and the possible impact of H2S on operations to be explored and practical experience of these aspects to

be achieved.

In the accumulating case study and later presentation, we were guided to develop this in a way that gave us valuable experience of approaching/dealing with the mock prospective client, including the production of an overall high-quality presentation with a balance of presentation skills and team coordination through presentation, all of which were developed through delivery and exposure to the task.

Throughout this programme, the technical lectures and opportunity for direct implementation of learnings from lectures have given me invaluable exposure to fields of asset integrity that I hadn’t previously been exposed to, as well as providing opportunities to develop further practical knowledge of aspects I am familiar with.

I believe that this programme has given me a stepping stone’ towards further progressing my career within asset integrity and has opened new career avenues on the back of it.

AMPP Member Leadership Development Programme

We all had the opportunity to enrol in AMPP’s Member Leadership Development Programme (MLDP) ahead of the conference. The intent of this programme was to provide enhanced leadership skills and training to members who may have an interest in serving in upper-level member leadership roles within the organisation in the future. The programme was led by Kim Ray, the Director of the EMERG Student Outreach Programme at AMPP, in partnership with Lauren Kaufman Blachman of Kaufman Blachman Consulting. The programme consisted of a series of learning sessions. On the Sunday preceding the conference, a full-day in-person event was organized, followed by five monthly online sessions. We have also participated in additional online meetings in which we, within groups of other participants on the programme, will later present the culmination of our work on a case study to the Joint Executive Committee of AMPP.

The leadership programme included training sessions that help provide a more in depth understanding of AMPP, its governance structure, the strategic plan, as well as its products, programmes, and services. In addition, participants would also intensify their own leadership skills with sessions in emotional intelligence, change management, communication skills, presentation skills, and much more. This special event kicked off on the first day of the conference. The morning session included an introduction to some members of the AMPP Joint Executive Committee and AMPP Chief Staff Officers who were available to come along to share their welcomes and provide positive insights into the programme. This initial in-person session, among other team building activities, included an Emotional Intelligence workshop providing a depth of personal insight in order to enhance our ability to use emotional intelligence to feel more positive and be a more effective influence throughout our personal and working lives. During this, there were several interactive break-out activities allowing for the opportunity to get acquainted with the American and other international participants and build relations that would be carried throughout the conference trip and furthermore into the rest of the MLDP programme.

This experience left me feeling much more confident to go forward with my leadership and management skills, as I was able to develop effective communication skills and an understanding of effective leadership. I feel much more confident going ahead as a leader to manage change. Also I have gained experience on how to navigate situations with heightened emotions effectively, being able to read a room and recognising what actions to take, through better emotional intelligence, depending on scenarios faced in professional and personal situations.

AMPP 2023 Conference + Expo

Due to the wide array of topics associated with materials protection (corrosion control and protective coatings), I planned my schedule to cover further development and advanced technologies in the field of plant inspection but also include a range of topics across the broader field. Kicking off on Sunday, the first day of the conference, proceedings consisted of a Coatings 101 workshop, which gave basic awareness of a typical protective coatings project, from understanding the need for a project and the selection of coating criteria to the unique challenges faced in the industrial coating industry. The afternoon consisted of a symposium on “Digital asset transformation: application of data science and analytics for corrosion management” – featuring a presentation on “eddy current array technologies, the utilisation of digital twin technologies for predictive corrosion and proactive management, and overviews of operators” developed holistic corrosion management software and dashboards. In the evening, we attended the opening reception for the conference. Monday included several symposia, including “Facilities integrity: day 1” (including presentations on tank linings and composite repairs), “Corrosion under insulation” (including presentations on the utilisation of on-line inspection and monitoring solutions for CUI management), and “materials and cost of corrosion” – including effective service forecasting assessments and initial material selection for the improved lifecycle and project costs. In the evening, we attended a meal with some senior ICorr members who attended the conference, including Stephen Tate (President), Gareth Hinds (Past President), Danny Burkle (CED Chair and past YEP attendee, from 2018’s winning team), and also Peter Elliot (former UMIST lecturer). Tuesday presented a busy day visiting symposiums on “sweet and sour corrosion”, “corrosion management”, “facilities integrity: Day 2”, “materials and integrity in oil sands”, “marine coatings and corrosion”. The most notable and interesting presentations I attended included a talk on “the importance of leadership in corrosion management” which stressed the importance of leadership as opposed to management in the success of a corrosion management programme. Another highlight was a presentation where a failure investigation was shared summarising the step-wise failure analysis to understand intergranular stress-corrosion cracking (IGSCC) failure mechanism observed for carbon steel pipelines and piping, believed to be related to the presence of mineral wool insulation of a certain vintage. Also included in these symposia was a presentation by one of our colleagues from the AMPP MLDP, a PHD student from Texas A&M University.

Tuesday evening was kicked off with a BP sponsored drinks reception, followed by the headlined EMERG Scholarship Awards Ceremony and Emerging Leaders Bash where we were presented with our certificates for the YEP programme. Wednesday was mainly focused on attendance of symposia on “Corrosion Protection in Offshore Wind” a topic that is new to myself but attendance provided great insight and learnings on the subject. This day also included the attendance to the Exhibition, sadly not making the putt for the chance to win a Scotty Cameron putter but was able to visit stands of a few of my company’s NDT equipment and condition monitoring suppliers for equipment demos. As part of the exhibition we also had the opportunity to get a walkthrough of paint inspection methods and equipment, and also visit the AMPP Student Poster presentations where a few of our colleagues from the MLDP were presenting.

On Thursday, the final day of the conference proceedings, symposia attended consisted of “Hydrotesting, Mothballing and Preservation” including failure investigations on stagnant lines and conclusion of presence of MIC, “Aboveground Storage Tank Bottom Cathodic Protection” including presentation on the findings of an off-line inspection and corrosion identification of a water storage tank and “Machine Learning for Corrosion Management” including overview of Ultrasonic Guided Wave techniques utilisation for machine learning for corrosion monitoring in Pipes. As part of the package for attending the Conference we also have access to the recorded sessions on-demand to revisit attended sessions or catch-up on sessions that we wished to attend but clashed with schedules at the time – so the takeaways from the conference are still very much ongoing, which is a huge benefit to my continued professional development. Through the exposure to a wide range of asset integrity innovations and in-development solutions, it has sparked a real interest to better understand these technologies and diversify my knowledge in subjects such as corrosion monitoring solutions and cathodic protection.

Conclusions

Overall, from the outset of the programme itself and the opportunities created following, the Young Engineer Programme has given so much exposure to field of corrosion, asset integrity and related topics. This has been such an invaluable experience, opening doors and my mind to further progression in my professional life.

Each aspect of this journey has afforded many networking opportunities to better integrate me as an individual in the asset integrity industry and develop professional relationships and rapports with subject matter experts in the fields of asset integrity.

I would like to thank ICorr, especially Yunnan Gao (ICorr’s Vice President), a former colleague at STORK and now with BP, for introducing me to the programme in the first place and would encourage any prospective candidates of the YEP programme to go for it and take hold of all the opportunities that are available from it.

ICorr Microbiologically-Influenced Corrosion (MIC) Courses

The next ICorr MIC course is scheduled for October at the headquarters in Northampton. MIC is one of the least understood corrosion phenomena, despite being responsible for a number of high-profile failures. The Aliso Canyon gas leak in 2015 was caused by external MIC rupturing a storage well and the civil lawsuits were settled for US$ 1.8 billion on 27/9/2021[1], on top of utility fines and the cost of repair and containment.

MIC phenomena affect all systems with even traces of water in most industries. Different microbial groups have been identified and are affecting most construction materials.

The ICorr course is the only MIC training programme that is certified by a recognised professional organisation.

Dates:

The awareness course is scheduled for 4/10/2024

The certified MIC technologist course is scheduled for 23/10 to 27/10/2024

Venue:

ICorr headquarters, Northampton, UK

Registration:

Email: admin@icorr.org

Telephone: +44 (0) 1604 438 222

(1) SoCalGas agrees to $1.8-billion settlement in 2015 gas leak – Los Angeles Times (latimes.com)

Institute News

AMPP 2023 VISIT – DENVER

The 2022 YEP programme was chaired during the year by Hooman Takhtechian FICorr, and has been previously documented at: https://www.icorr.org/young-engineers-programme-yep-winners-night/ and see also (24) Post | LinkedIn

AMPP 2023 VISIT – DENVER

The five winning YEP delegates listed below all attended the 2023 AMPP exhibition, full conference, and leadership programme. The Institute of Corrosion is extremely grateful to AMPP, and to BP (our key sponsor) for making this all possible. Each of the YEP participants has produced a comprehensive journal, and these will be published in subsequent issues of the magazine (the first appears in this issue), as we move towards the start of the YEP 2024 programme.

YEP delegates at AMPP in 2023 were:

• Christopher Slater

• Eilidh MacDonald

• Jamie Hillier

• Lee Hunter

• Praveena Nanthakumaran, (who was on the winning team for the 2020 YEP competition but was unable to attend at that time)

Rosie Bird (from the 2022 winning team) was unfortunately not able to go to the AMPP event this year but it has been agreed that she will attend AMPP in 2025, alongside the 2024 winning team.

During October 2023, the winning students will make a presentation of their experiences to Aberdeen branch, and this will be available to all ICorr members, as a hybrid event to which AMPP and Young ICorr members will be invited.

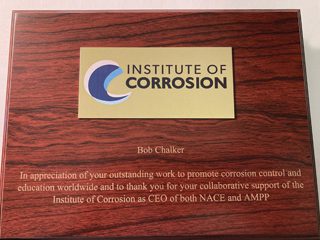

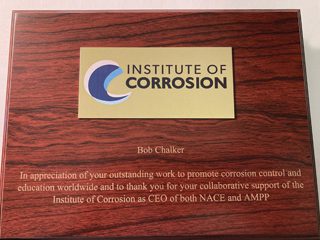

AMPP Retiring President

During the AMPP 23 event, a “thank you” plaque was presented to retiring AMPP CEO – Bob Chalker. Bob will be succeeded by Alan Thomas with a 2 month handover until July 2023.

The YEP wishes to express its gratitude to all the AMPP, BP and ICorr management teams, for their support and assistance provided for their 2023 visit, which was a huge success and greatly enjoyed by all. Some of the YEP winners’ comments are extracted here below, and their full journals will be published as space permits

YEP / AMPP – Delegate Feedback

• The YEP programme was a huge success. I developed my technical, communication, leadership, and teamwork skills, to a huge extent. I got to play so many different roles that I simply would not get exposure to during my usual day job as subsea engineer. At times I felt like a leader, a follower, a technical consultant, and a salesman. The value of the programme was really demonstrated to me through the opportunity to play these roles, (Jamie Hillier – Senior Subsea Engineer at Xodus Group, Aberdeen).

• If you are just starting your career as a young engineer and are interested in corrosion, I highly recommend applying for the ICorr’s YEP. It was an eye-opening experience. I have learned from SMEs in the industry, made fantastic friends along the way, and gained new and exciting opportunities through the programme. Additionally, the AMPP conference (and Leadership programme) winner’s prize, is incredibly valuable for knowledge transfer, networking, and potentially finding new clients or services for your company, (Praveena Nanthakumaran – Mechanical Engineering Graduate at Worley, London).

YEP – AMPP Visit prize – Leadership Programme / Conference / Exhibition / Awards

• On arrival at the event, we participated in a team building activity after being familiarised with the Drexler-Sibbet team performance model. This was a great way to get involved with other participants and build connections with them. The ‘carpet maze’ required us to work as a team to figure out the correct route to cross the mat without being able to talk to each other, in a limited time frame. This exercise was a practical way to teach us certain things that are directly applicable to the problems we face in a professional setting. Often, we just see our end goal, but to achieve this, mistakes will be made, side steps will need to be taken, and sometimes you even need to go backwards – it’s never just a straight route! (Eilidh MacDonald – Coatings Engineer at Subsea7, Aberdeen).

• The leadership programme experience left me feeling much more confident to go forward with my leadership and management skills, as I was able to develop effective communication skills. It gave me a good understanding of effective leadership, to make me feel much more confident going ahead as a leader to manage change. Also increasing my experience on how to navigate situations with heightened emotions effectively, being able to read a room and recognising what actions to take, through better emotional intelligence, depending on scenarios faced in professional and personal situations, (Christopher Slater – Project Engineer at STORK, Aberdeen).

AMPP 23 Conference – Participant Feedback

• I realised just how busy this conference was when I tried go to the Surface Preparation lectures – there wasn’t even standing room left! (Eilidh MacDonald – Coatings Engineer at Subsea7, Aberdeen).

• The AMPP seminars provided practical tips and strategies for overcoming challenges, and the opportunity to learn from industry experts was invaluable. I left the conference feeling inspired and motivated to apply the knowledge and insights I

had gained to my work, (Lee Hunter – Operations Manager at

AIM Group, Aberdeen).

AMPP 23 Exhibition – Participant Feedback

• Highlights of the exhibition for me were spending time discussing technologies on the market with various vendors. This included talking through pigging solutions to wax-filled pipelines, retrofit ICCP system solutions, and remote UT monitoring sensors. Being able to discuss these technologies and then bring back learnings from them into projects I’m working on would’ve been worth the trip to Denver alone, (Jamie Hillier – Senior Subsea Engineer at Xodus Group, Aberdeen).

• I was impressed by the diversity of the AMPP exhibitors and the range of products and services they offered. From coatings and corrosion protection solutions to equipment and instrumentation, the exhibitor hall had something for everyone, (Lee Hunter – Operations Manager at AIM Group, Aberdeen).

AMPP 23 Awards – Participant Feedback

• The EMERG Leaders Awards Ceremony at the Filmore in Denver, sponsored by BP was absolutely fantastic, and we were invited on stage to receive our ICorr YEP awards from Stephen Tate. It was also great to celebrate the achievement with the friends we had made on the MDLP earlier in the week, some of whom were also receiving awards that night. The atmosphere, the band, and the food (and drinks!) were great, and the night was definitely my highlight of the trip, (Eilidh MacDonald – Coatings Engineer at Subsea7, Aberdeen).

• The evening of entertainment and networking that followed the ceremony was a great opportunity to connect with like-minded professionals and learn from their experiences. Overall, it was a truly memorable event, and I feel privileged to have been a part of it, (Lee Hunter – Operations Manager at AIM Group, Aberdeen).

YEP 2024

We look forward, of course, to the next YEP competition, starting in January 2024, which will be managed by our very successful YICorr division, and take place in London. This 11-month programme provides a great opportunity for young engineers to expand their knowledge in corrosion management and engineering, and to combine it with their experience in energy and other industries.

The programme is designed to offer the following benefits:

1. Attendees will gain practical skills and knowledge on key issues in the energy industries, including Net-Zero technologies.

2. The lectures and workshops will form part of Continuing Professional Development (CPD) for the Institute of Corrosion. Additional attendance at local branch technical meetings will be encouraged where possible.

3. Attendees will develop teamwork and presentation skills from the workshops.

4. CPD points will contribute to participants’ progression to MICorr and Chartership.

5. Excellent opportunities for networking.

6. Increasing the skill level for engineers and decreasing the gap in knowledge between new and senior engineers, overall facilitating a better working environment within the sector.

All students will go through a series of evening lectures and be given a case study. Events will be held once a month from January to November (excluding August). Following is a list of the topics covered during the programme:

• Fundamentals of Corrosion • Cathodic Protection.

• Coatings & Linings

• Corrosion under Insulation/Fire Proofing

• Integrity Management / Fitness for Service

• Materials / Welding • NDT and Corrosion Monitoring

• Production Chemistry / Chemical Treatments

• Presentation Skills, (in the form of ‘How to solve a corrosion case study’ – This will cover the basics to presentation skills anecdotally but importantly teach the participants the keys to problem solving in the corrosion world)

James McGladdery will co-ordinate the next programme on behalf of YICorr, who can be contacted at:

James.McGladdery@uknnl.com, Tel: +44 (0)1946 556 600

Denver Conference Centre, Colorado.

YEP Winners, BP Sponsor and President at AMPP 2023 – (L to R),

Praveena Nanthakumaran, Eilidh MacDonald, Jamie Hillier, Timothy Bieri, Stephen Tate, Lee Hunter and Christopher Slater.

Presentation of the YEP Awards at the Filmore.

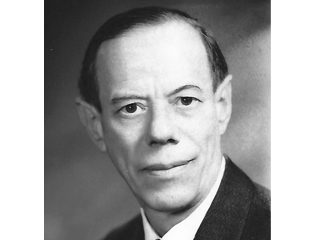

Plaque to Bob Chalker, retiring CEO of AMPP.

Institute News

Each year, the Institute of Corrosion bestows a range of internationally renowned awards in recognition of excellence in corrosion science and engineering, and to reward outstanding service to the Institute and the wider corrosion community.

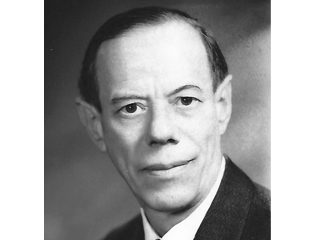

The institute is extremely proud to announce the selection of Trevor Osborne, FICorr (Hon), NACE Corrosion Specialist, for the H.G. Cole Award.

This award is made in recognition of exceptional services to the development of the Institute. It is only awarded on an occasional basis, reflecting the highest possible level of commitment of the recipient to the activities of the Institute. The inaugural H.G. Cole Award (in the form of a poignard) was presented to Charles Booker in 1997 by Gwen Cole (wife of the late Henry Cole), in recognition of his many years of service as Honorary Secretary of the Institute. The modern form of the award is a plaque whose design captures the essence of the original poignard.

Trevor is a past president of the Institute of Corrosion and a long-standing chair of the board of its commercial arm, Correx Ltd. He is managing director of Deepwater Corrosion Services (UK) Ltd., and has worked in the energy industry for over 43 years, with very wide experience in corrosion control and project execution. He will be presented with the award at the Institute AGM to be held on November 8, 2023, in Birmingham.

We offer our sincere congratulations to Trevor on this magnificent achievement.

Background to the H.G. Cole Award

Henry George Cole was the chief materials engineer at the UK Ministry of Defence. He was based in London and Farnborough, and was a hugely respected coordinator and sponsor of research, an elegant and influential ‘Whitehall Mandarin’, and a man of spectacular vision and determination. He was Secretary to the Hoar Committee, a ground-breaking development for the recognition of corrosion costs in the early 1970s that was the mainspring for corrosion interest in UK government circles for the next twenty years. Henry Cole was also hugely committed to the Institute of Corrosion. He became the part-time administrative officer for the institute when it shared accommodation with the SCI at Belgrave Square. He oversaw the Institute’s move to the IMF offices in Birmingham and he was one of the guiding lights of the Institute until his untimely death on 14th May 1987.

Trevor’s Legacy

Trevor has made an outstanding contribution to the long-term financial sustainability of the institute in a variety of roles over many years. He has guided the Institute financially by overseeing the continued success of our ICATS training scheme in his role as Chair of the Correx Board, and by coordinating sound investments on our behalf. In addition, before retiring from Council in 2022, Trevor spearheaded the purchase and refurbishment of a new headquarters for the Institute – ‘Corrosion House’ in Northampton.

This is a ‘state of the art’ 3-storey building, with the ground floor dedicated to the HQ administration team, the middle floor for training, and the top floor as a conference room. Each floor has its own kitchen, and the corrosion training centre has a breakout facility for delegates.

Corrosion House is undoubtedly a world class facility, totally fitting for the Institute of Corrosion, and based in a location in easy reach for both national and global customers, that today welcomes customers and members from all over the world.

More information on the H.G. Cole Award can be found on the Awards page of the ICorr Website:

https://www.icorr.org/icorr-awards/