Sustainable C5 Corrosion Protection for Primer Coatings

According to Hexigone, their latest test results prove that their sustainable corrosion inhibitor, Intelli-ion AX1, can reach C5 levels of corrosion protection in both waterborne and solvent borne coatings.

C1–C5 are classifications used to describe the level of corrosion resistance required for aggressive environments and applications. C5 refers to highly corrosive environments where the steel structure is exposed to high levels of humidity, saltwater spray, and other corrosive substances.

The coatings that were tested were specially formulated by a UK-based organisation that provides technical and scientific support to the global coatings industry. The REACH compliant inhibitors were added to both waterborne (WB) and solvent borne (SB) 2 pack epoxy coatings, and both primer only and top-coated systems were tested.

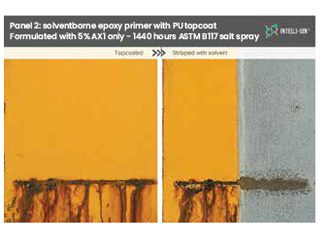

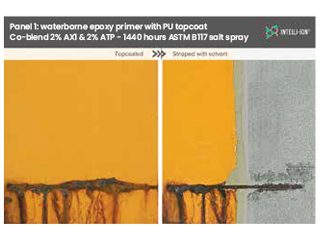

The panels used for testing were shot-blasted to Sa 2.5 as per C5 specification. Each primer layer had an average dry film thickness (DFT) of 120 µm, and the topcoat was applied at approx. 60 µm. After 1440 hours salt spray (SST) to ASTM B117 both the primer and full system for the WB epoxy and SB epoxy displayed no signs of blistering in the coating. To demonstrate the full performance of both systems with AX1 in, part of the paint system was removed after salt spray to view the substrate underneath. The WB epoxy system after 1440 hours shows minimum corrosion at the scribe, evidencing Intelli-ion’s excellent performance in WB systems. The SB epoxy system also meets specifications with no blistering, minimum cross-scribe corrosion, and no undercoat corrosion present on the full substrate.

Unlike zinc phosphate, which primarily provides anodic protection via precipitation, Intelli-ion offers both anodic and cathodic corrosion protection. The technology is released in a smart way and works by forming a protective nano layer on the metal surface, which provides a physical barrier to corrosion-inducing substances. The final mode of protection happens once it has donated a proton to OH- ions resulting from the cathodic oxygen reduction reaction, it forms a lone pair bonded layer over the metal surface at the cathode, blocking interfacial electron transfer.

Hexigone invites coatings manufacturers worldwide to join forces and co-create high-performance, sustainable, smart coatings.

For more information visit https://www.hexigone.com