The Aberdeen Branch hosted the Young Engineer Programme (YEP) 2022 final on 24th November ’22, at the Palm Court Hotel, which was attended by over 40 in person, plus around 15 attendees online.

It was more than 18 months ago that the branch first considered hosting this event in Scotland, after 3 very successful events hosted by London Branch. David Mobbs, Trevor Osborne, and Danny Burkle, all very kindly supported the branch in the early days of YEP 2022.

The Young Engineer’s Programme was conceived some 10 years ago by the ICorr London Branch, and has been generously sponsored since then by BP, with the following in mind, perceived skill shortages in the industry, preparing graduates for entry into the industry with an enhanced skillset, and to be the first stage in achieving MICorr / CEng.

The ICorr YEP remains extremely popular with our younger and aspiring corrosion engineers, and this 4th YEP had 24 candidates, selected from over 50 applicants The Institute is very grateful to the Aberdeen committee who worked hard, especially Hooman Takhtechian (2021-2022 session chair) and Steve Paterson (YEP mentor supervisor / Case study organiser), superbly supported on the night and throughout the YEP by, Muhammad Ejaz / Adesiji Anjorin, the current branch chair and vice chair respectively.

This year’s selection criteria were:

• Early stage of their career related to corrosion.

• 2 to 6 years relevant experience.

• 35 and under.

• Relevant academic background.

• Based in Aberdeen, or willing to travel at their own cost.

The YEP committee had great difficulty in selecting those to go forward. The case study teams were based on their experience, academic background, and employer, to ensure not being in the same company as the other team members or the mentor, with the average experience for each team being 4 to 4.5 years.

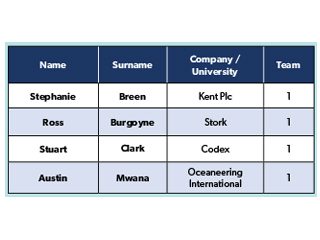

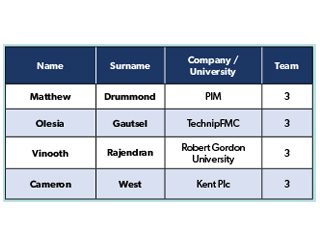

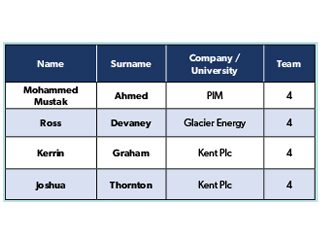

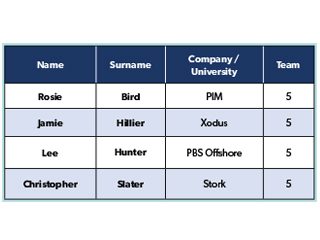

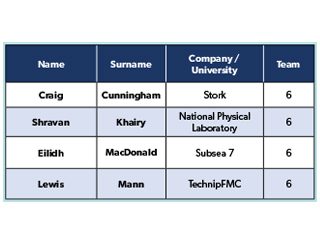

YEP 2022 Participants

The 2022 case study exercise was complex, and focused on good corrosion management approaches under difficult conditions, requiring careful consideration of:

• A 15 year old offshore platform in sweet service.

• Poor corrosion management to date.

• Possible new owner with another 10 years’ service.

• Possible tie-in of new field with slightly sour fluids.

• Dealing with an intermediary integrity services contractor.

• Difficult and demanding client.

• Subsidiary of international operator.

• Based on an actual platform in the North Sea.

• High level assessment (and ranking) of threats.

• Mitigation measures – corrosion management system.

• Material options for required new pipeline.

•

The management and impact of change in operations (MOC).

• Identifying all other relevant factors in dealing with client.

YEP 2022 Participants

The 2022 case study exercise was complex, and focused on good corrosion management approaches under difficult conditions, requiring careful consideration of:

• A 15 year old offshore platform in sweet service.

• Poor corrosion management to date.

• Possible new owner with another 10 years’ service.

• Possible tie-in of new field with slightly sour fluids.

• Dealing with an intermediary integrity services contractor.

• Difficult and demanding client.

• Subsidiary of international operator.

• Based on an actual platform in the North Sea.

• High level assessment (and ranking) of threats.

• Mitigation measures – corrosion management system.

• Material options for required new pipeline.

• The management and impact of change in operations (MOC).

• Identifying all other relevant factors in dealing with client.

Some key aspects of the exercise were to:

• Analyse and discuss the information and data provided.

• Identify any gaps in information and any assumptions that may need to be made.

• Perform a high-level risk assessment to identify key threats to the mechanical integrity of the pressurised systems (structural integrity was excluded).

• Identify what further information or data required for the other tasks in the exercise.

• Propose a systematic approach to manage the key threats including mitigation measures, corrosion control requirements, performance monitoring, and the resources required to manage the process.

• Propose materials of construction for a pipeline, including welding consumables, and any testing requirements to tie-back the new reservoir to the platform, and explain the basis for the materials selection and how any corrosion threats will be mitigated.

• Identify what changes, if any, to the existing facilities would be required should the new sour reservoir be tied-back to the platform.

• Propose a strategy for convincing Capercaillie Energy (the integrity management contractor) that your approach is the optimal solution and that you are the right team to do the job.

The marking criteria for the YEP case study presentation were:

1. Analysis of the scenario and current integrity status of the pressurised systems of the platform (20 marks).

2. Application of a systematic methodology to manage corrosion and surveillance activities (20 marks).

3. Viability of the proposed approach to prolong service life (10 marks).

4. Assessment of material options for the new pipeline (10 marks).

5. Assessment of the impact of change in operation with H2S (10 marks).

6. Identification and assessment of factors in dealing with the client (10 marks).

7. Overall quality and balance of the presentation, plus team coordination as demonstrated by the presentation (20 marks). Only 20mins were allowed per team for their presentation, with strict penalties being applied for those going over.

The Aberdeen committee would like to offer its special thanks to all of the following lecturers, mentors, and judges.

YEP 2022 course lecturers

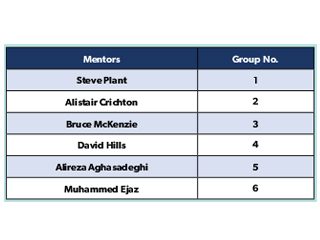

The YEP course mentors were:

The judges on the night were:

• Chris Williams, (BP Sunbury – Key Sponsor).

• Susan Cushnaghan, (formerly of Shell Aberdeen).

• Stephen Tate (2022-2024 ICorr President).

All the participating teams engaged fully with the brief and gave a tremendous series of presentations providing many different solutions to the task in hand including net zero considerations, their enthusiasm was a joy to watch.

Unfortunately. Teams 2 and 6 were missing colleagues on the night due to illness, but they still performed brilliantly.

Team members

It was a very hard decision for the judges, but in the end Team 5 stood out as the best all-rounders and enactors of the task in hand. The Institute offers their warmest congratulations to all the Team 5 members, as they head off to AMPP Annual Conference & Expo 2023 19-23 March, all expenses paid courtesy of key sponsor, BP.

Winner of the Leadership Prize

After receiving feedback from all the mentors, judges and committee members, based on the performance during the whole programme, teamwork and presentation skills on the competition evening, Eilidh Macdonald was selected as the outstanding YEP 2022 individual participant. The Institute also offers their congratulations to Eilidh on receiving this recognition, who will also be eligible to attend the AMPP leadership course, all expenses paid. This is very well deserved.

Some key aspects of the exercise were to:

• Analyse and discuss the information and data provided.

• Identify any gaps in information and any assumptions that may need to be made.

• Perform a high-level risk assessment to identify key threats to the mechanical integrity of the pressurised systems (structural integrity was excluded).

• Identify what further information or data required for the other tasks in the exercise.

• Propose a systematic approach to manage the key threats including mitigation measures, corrosion control requirements, performance monitoring, and the resources required to manage the process.

• Propose materials of construction for a pipeline, including welding consumables, and any testing requirements to tie-back the new reservoir to the platform, and explain the basis for the materials selection and how any corrosion threats will be mitigated.

• Identify what changes, if any, to the existing facilities would be required should the new sour reservoir be tied-back to the platform.

• Propose a strategy for convincing Capercaillie Energy (the integrity management contractor) that your approach is the optimal solution and that you are the right team to do the job.

The marking criteria for the YEP case study presentation were:

1. Analysis of the scenario and current integrity status of the pressurised systems of the platform (20 marks).

2. Application of a systematic methodology to manage corrosion and surveillance activities (20 marks).

3. Viability of the proposed approach to prolong service life (10 marks).

4. Assessment of material options for the new pipeline (10 marks).

5. Assessment of the impact of change in operation with H2S (10 marks).

6. Identification and assessment of factors in dealing with the client (10 marks).

7. Overall quality and balance of the presentation, plus team coordination as demonstrated by the presentation (20 marks).

Only 20mins were allowed per team for their presentation, with strict penalties being applied for those going over.

The Aberdeen committee would like to offer its special thanks to all of the following lecturers, mentors, and judges.

YEP 2022 course lecturers

The YEP course mentors were:

The judges on the night were:

• Chris Williams, (BP Sunbury – Key Sponsor).

• Susan Cushnaghan, (formerly of Shell Aberdeen).

• Stephen Tate (2022-2024 ICorr President).

All the participating teams engaged fully with the brief and gave a tremendous series of presentations providing many different solutions to the task in hand including net zero considerations, their enthusiasm was a joy to watch.

Unfortunately. Teams 2 and 6 were missing colleagues on the night due to illness, but they still performed brilliantly.

Team members

It was a very hard decision for the judges, but in the end Team 5 stood out as the best all-rounders and enactors of the task in hand. The Institute offers their warmest congratulations to all the Team 5 members, as they head off to AMPP Annual Conference & Expo 2023 19-23 March, all expenses paid courtesy of key sponsor, BP.

Winner of the Leadership Prize

After receiving feedback from all the mentors, judges and committee members, based on the performance during the whole programme, teamwork and presentation skills on the competition evening, Eilidh Macdonald was selected as the outstanding YEP 2022 individual participant. The Institute also offers their congratulations to Eilidh on receiving this recognition, who will also be eligible to attend the AMPP leadership course, all expenses paid. This is very well deserved.

YEP 2024

The Institute are already planning for YEP 2024, which will be managed by the Young ICorr Division.

Details will be announced later during 2023, however interested parties can register their advance interest

to the new YICorr chair, James McGladdery,

James.McGladdery@uknnl.com

Eilidh MacDonald from Team 6, Winner of the Leadership Prize.

CAPTIONS:

YEP 2022 coordinator, Hooman Takhtechian.

YEP 2022 case study lead, and the ICorr CED All Energy chair, Steve Paterson, explains proceedings.

Contestants, mentors, judges and ABZ committee members on the night.

The YEP 2022 winning team 5, Judges, President, and team 5 mentor. From left to right, Rosie Bird, Lee Hunter, Jamie Hillier, Chris Williams (Judge), Susan Cushnaghan (Judge), Stephen Tate (Judge), Christopher Slater, Alireza Aghasadeghi (mentor), and Steve Paterson (Case study lead).

Team 1

Team2

Team 3

Team 4

Team 5

Team 6