Examining the Use of Low-Zinc Epoxy Primers

In an Ask the Expert Article in which a reader asks the question, “Do these (low-zinc) primers still provide good galvanic corrosion protection and maintain good adhesion and mechanical properties of the dried film?”, the answer includes the following explanation:

“Formulation of an effective zinc-rich or reduced zinc primer requires a high degree of effort (or luck!) on the part of the formulator – it is not just a case of putting in a high loading of zinc and hoping for the best.”

When it comes to protective coatings, zinc epoxy primers are a critical component in safeguarding metal surfaces. These primers are renowned for their corrosion resistance and durability. But how do you know which is the correct one for your application?

Unpacking the Role of Zinc in Epoxy Primers

The efficacy of zinc in epoxy primers can’t be overstated. To truly appreciate its role, we need to delve into the chemistry and physics of how these primers work.

Zinc acts as a sacrificial anode. When applied over metal surfaces, it reacts preferentially with the oxygen and moisture in the environment, corroding itself instead of allowing the underlying metal to rust. This process, known as cathodic protection, is central to the protective qualities of epoxy primers.

But the role of zinc extends beyond just preventing rust. It also contributes significantly to the primer’s adhesion properties. The presence of zinc particles creates a rougher surface at a microscopic level. This increased surface roughness enhances the mechanical adhesion between the primer and the metal substrate, ensuring a stronger bond and a more durable protective layer.

Moreover, zinc contributes to the overall mechanical strength of the dried film. It helps in forming a dense, impermeable barrier that is resistant to scratches and impacts. This is particularly important in harsh industrial environments where mechanical wear and tear are common.

Furthermore, zinc’s role is not just limited to protection and adhesion. It also affects the primer’s electrical properties. Zinc-rich primers can provide a certain level of conductivity, which is beneficial in preventing static charge build-up on the surface. This property is particularly valuable in certain industrial applications where static electricity can pose a significant risk.

In essence, zinc is a multifaceted player in epoxy primers. Its contribution goes beyond mere surface-level protection, impacting the primer’s physical, chemical, and electrical properties. Understanding these aspects is crucial when considering the implications of reducing zinc levels in these formulations.

The Low-Down on Low Zinc Levels

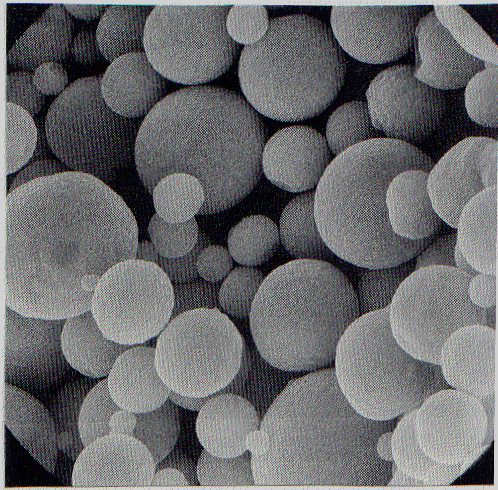

The formulation of the primer plays a crucial role. The type and amount of zinc, the particle size, and the distribution of zinc within the epoxy matrix are all critical factors that influence the primer’s performance. Advanced formulations aim to optimise these factors to ensure maximum protection with minimum zinc content.

What exactly constitutes a ‘low zinc level’ in these primers? Typically, it refers to formulations where the zinc content is significantly reduced compared to traditional mixes.

Most standards and specifications require at least 77% of weight of zinc dust in dried film to meet the performance demands. For example, standards for zinc levels in coatings include:

- ISO 12944 = “zinc rich” >80% (Zinc dust on dry film)

- BS5493 = “zinc rich” >95% (Zinc dust on weight of pigment)

- BS4652 = “zinc rich” >85% (Zinc metal on dry film)

However, protective primers are increasingly formulated using lower levels of zinc, with a process that ensures the zinc dust particles are not totally encased by the binder. This makes sure that the zinc is still able to react with the external environment.

The shift towards these low-zinc formulations is often driven by cost reduction, easier application processes, and environmental considerations.

Investigating Adhesion Properties

Zinc plays a pivotal role in ensuring that an epoxy primer adheres to metal surfaces. There’s a complex interplay of chemical and mechanical bonding that occurs, and zinc dust particles contribute to both:

- Chemically, zinc can react with the metal surface, enhancing the bind between primer and metal

- Mechanically, zinc particles create a rougher texture, which in turn provides greater grip and stronger adhesion

Tests are carried out to measure adhesive strength of low-zinc primers under different conditions, including exposure to moisture, temperature variations, and mechanical stress.

It’s also crucial to consider adhesion longevity, for over time environmental factors (like UV exposure, corrosion, and thermal cycling} can lead to degradation of adhesion. In this regard, zinc’s protective qualities can help to prolong a bond’s lifespan by shielding the metal surface from these elements.

We also need to consider how a primer is applied to a metal surface. Factors like surface preparation, primer thickness, and curing conditions can significantly affect the end result. ICorr’s Coating and Inspection courses ensure that applicators and inspectors understand the science behind effective use of zinc primers and use this knowledge effectively in the field.

We also need to remember that theoretical and real-world performance of coatings can vary dramatically. It’s crucial that we ensure feedback loops to inform research and innovation.

Exploring Mechanical Properties

The mechanical properties of zinc epoxy primers are critical to their performance. The following aspects must be considered when formulating and using zinc epoxy primers:

· Durability and Resistance to Wear

Zinc plays a pivotal role in a primer’s resistance to wear. Tests like Taber Abrasion and Impact Resistance provide crucial data that informs us of the durability of lower-zinc formulations.

· Flexibility and Resistance to Cracking

Especially for structures that are subject to thermal expansion or mechanical stress, the flexibility of a primer is important. They must be able to flex without cracking or loss of adhesion. Here, we might look at studies on elasticity and tests of tensile strength of low-zinc primers when considering the ability to maintain integrity under stress.

· Effect of Environmental Factors

Zinc has proactive qualities that contribute to shielding an underlying metal from environmental factors such as UV radiation, extreme temperatures, and corrosive environments. Therefore, it’s also crucial to assess how reduced zinc levels in a primer will affect performance in the environment in which the structure exists.

· Resistance to Chemicals

Chemical resistance testing provides valuable insight into the suitability of low-zinc primers when they are required to resist the effects of chemicals, oils, and solvents – exactly the type of environment in which many industrial applications are needed.

In addition to the above, we also need to consider the correlation between adhesion and mechanical properties, and how zinc levels affect this.

Finally, when considering the use of lower-zinc epoxy primers, it’s crucial to include discussions about longevity and maintenance requirements. An analysis of primer performance over time – including consideration of repair needs – will help to assess overall cost effectiveness over the lifetime of the structure.

Navigating the Trade-Offs

Selecting the best zinc epoxy primer requires careful consideration of various factors. As we move toward lower-zinc formulations, we must consider the following trade-offs:

· Balancing Cost and Performance

Do lower upfront costs offset potential increase in maintenance or a possible reduction in the longevity of the coating?

· Environmental Considerations

Reducing zinc use can result in lower environmental impacts, reducing mining as an example. Reducing zinc levels can lower toxicity and improve working conditions. But are they sustainable?

· Performance in Industry-Specific Conditions

Each industry has unique requirements. Maritime industries require primers to withstand harsh, moist and salt-heavy conditions. Onshore infrastructure may prioritise flexibility and UV resistance. We need to be certain that suitable primers are used for each unique need.

· Innovations in Formulations

As our knowledge of how alternative compounds can complement the protective qualities of zinc, we have been able to develop new formulations that meet the dual demands of performance and sustainability.

· Regulatory Compliance and Safety Standards

We need to consider current and updated regulations and compliance with international standards, as well as paying heed to health and safety requirements. Low-zinc primers must meet the same rigorous standards as traditional formulations.

· Long-Term Implications and Lifecycle Analysis

Finally, it’s essential to consider the long-term implications of low-zinc primers. This includes a lifecycle analysis of the coating, considering factors like frequency of reapplication, ease of repair, and eventual disposal. Understanding the full lifecycle impact of these primers can provide a more comprehensive view of their cost-effectiveness and environmental footprint.

The Bottom Line for Low-Zinc Epoxy Primers

There are compelling arguments for the use of low-zinc epoxy primers. However, when doing so, we must consider a multitude of factors.

When considering the trade-offs, we must make informed decisions, balancing cost-effectiveness, environmental friendliness, and performance. Only then can we select solutions that align with needs, budgetary constraints, environmental responsibilities, and regulatory requirements.

We also need to remain updated with the evolution of innovations in this field, as academia and engineering collaborate to expand the capabilities and applications of corrosion prevention and protection products and techniques.

Do you work with coatings to protect metal from corrosion? If you’d like to know more about ICorr’s training schemes for applicators and inspectors, click on the following links: